Method and System for Semi-Chemical Pulping

a semi-chemical and pulping technology, applied in the field of semi-chemical pulping, can solve the problems of clogging or coating, inability to perform multi-stage cooking processes, and having to shut down and clean the digester, so as to reduce the cost of production, reduce the cost of operation, and improve the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

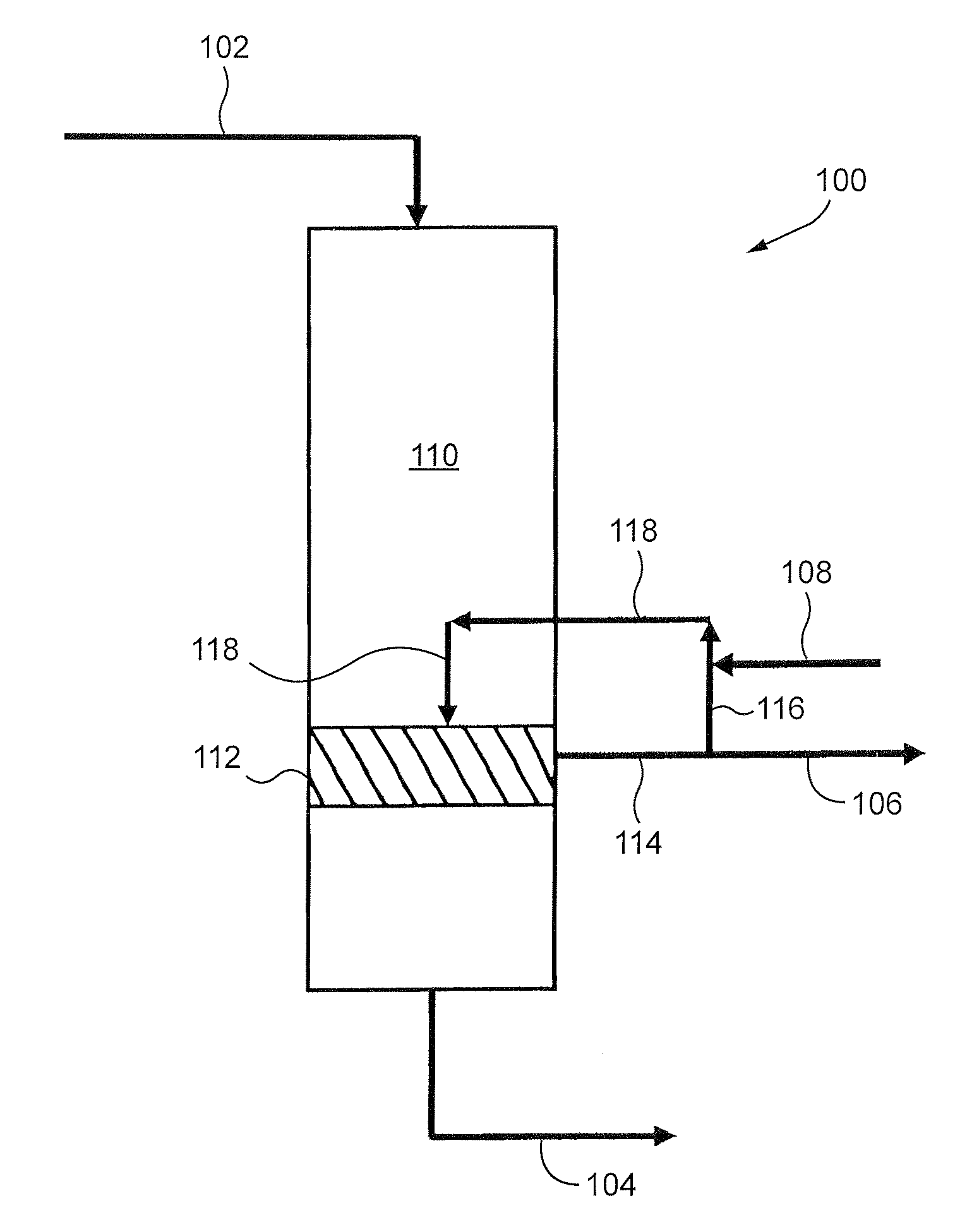

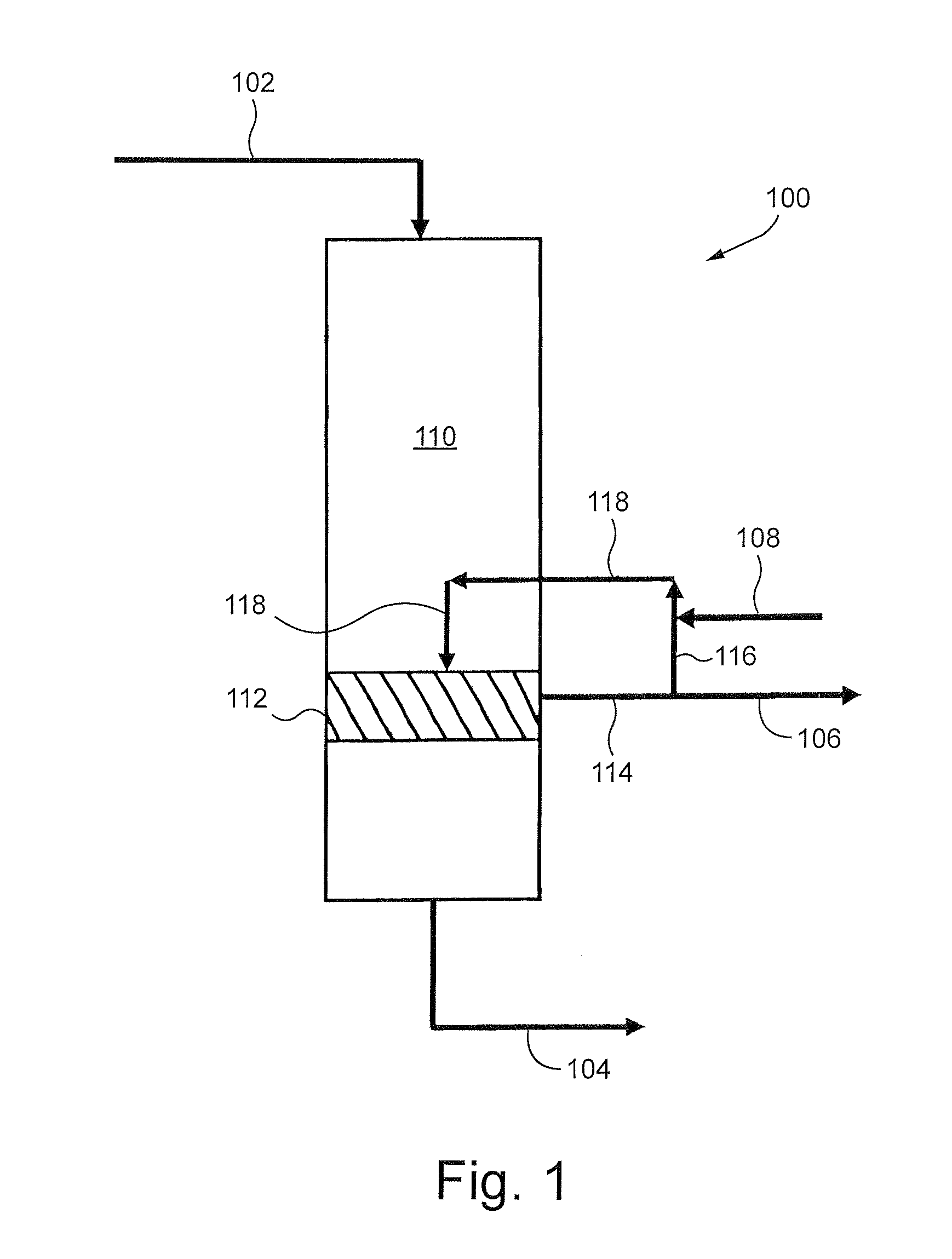

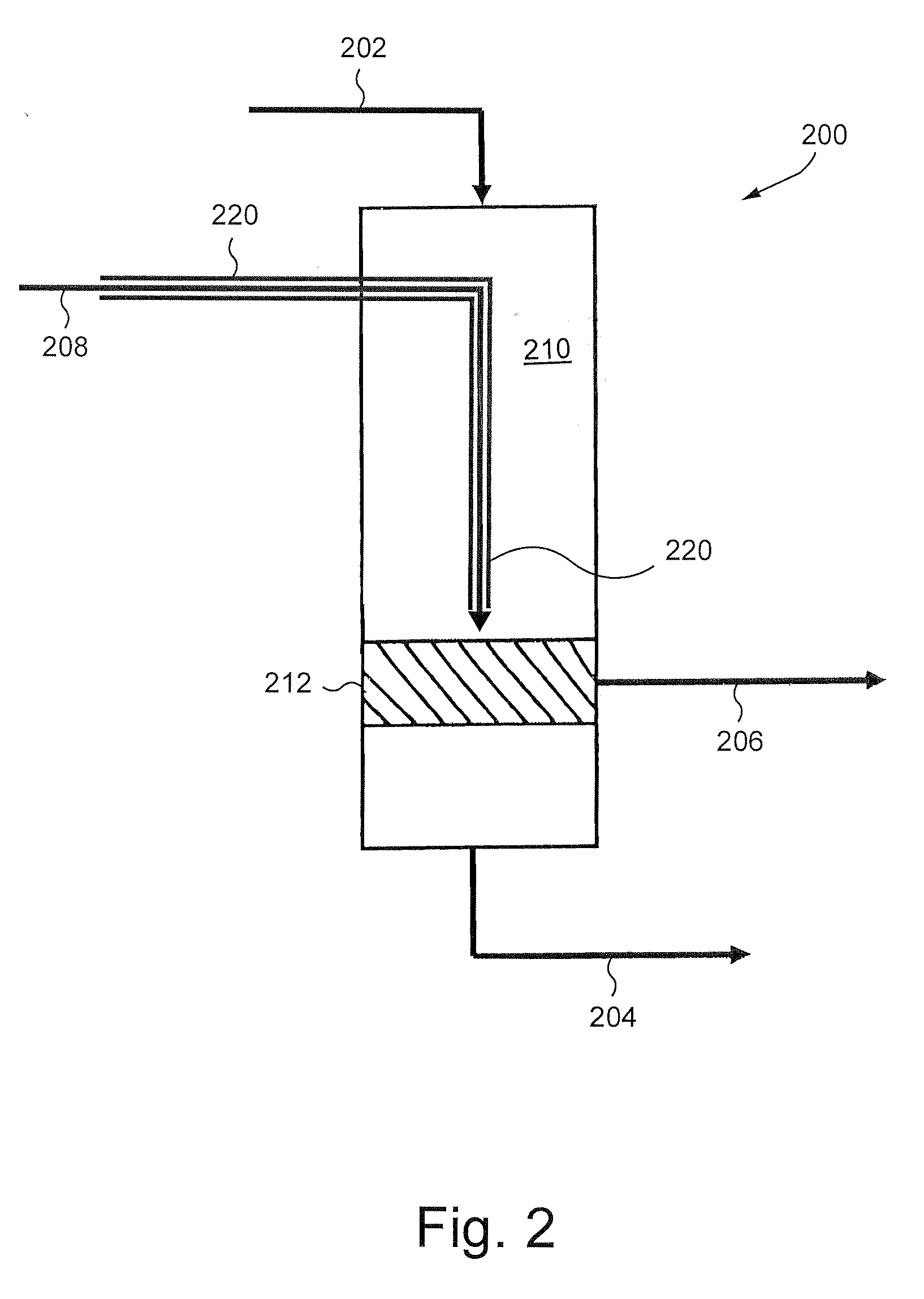

[0014]In one aspect, certain embodiments of the present invention generally relate to increasing the pH at the end of the cook. This may keep the screens cleaner for a longer period of time. The increased pH may be accomplished by adding white liquor or NaOH (or any other base) through a circulation and / or central pipe at the end of the cook.

[0015]The pH of the cooking liquor (e.g., black liquor with lignin) at the end of the cook should be 10 or higher, preferable between 10 and 13, and most preferably between 10 and 12.

[0016]In accordance with certain embodiments of the present invention, the pH at or near the extraction screen(s) may be elevated when compared with the pH of liquor above the extraction screens. This, in turn, may increase the solubility of the lignin at or near the extraction screen(s).

[0017]In certain embodiments, the pH level is raised of a liquid at or near an extraction screen of a vessel in which semi-chemical pulping is performed. In certain embodiments, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com