Cavity wall spacer, building structure and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In the following description, numerous specific details are set forth in order to provide a more thorough description of the present invention. It will be apparent, however, to one skilled in the art, that the present invention may be practiced without these specific details. In other instances, well-known features have not been described in detail so as not to obscure the invention.

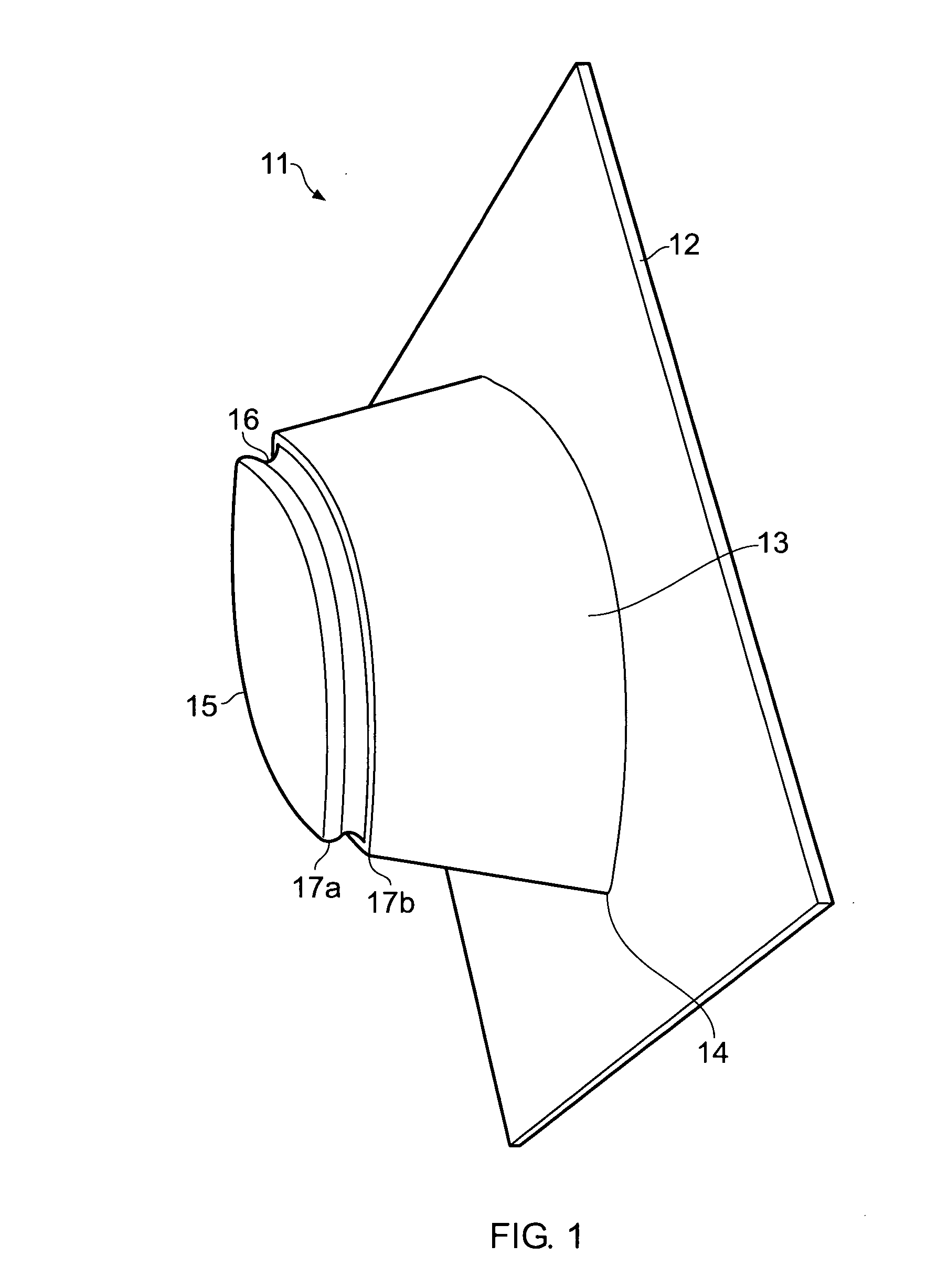

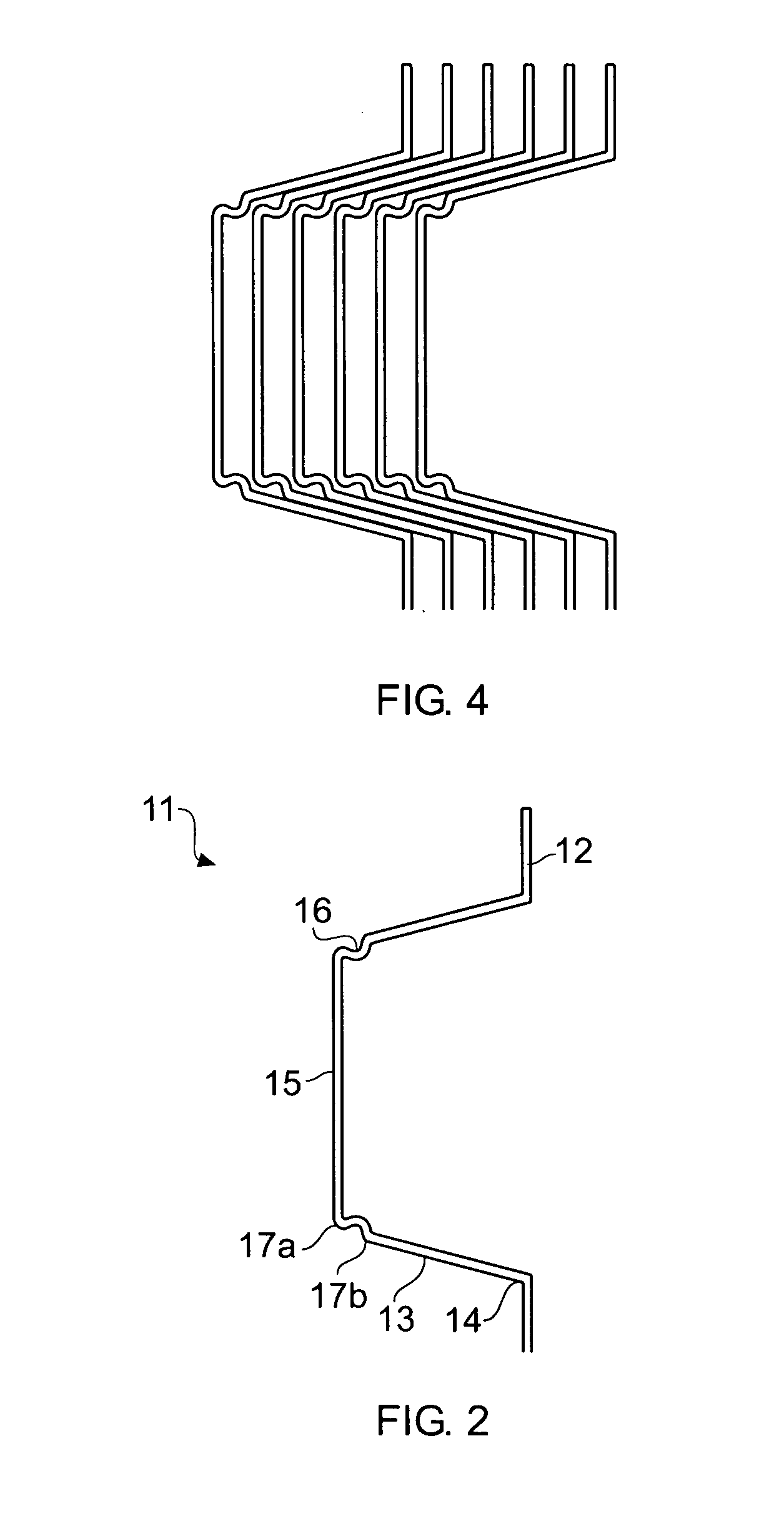

[0040]For a cavity wall to effectively work as a moisture barrier, the cavity or gap should not be bridged in any way. A cavity wall spacer may be used to inhibit the transfer of moisture from the exterior leaf to the interior leaf in one or more embodiments. GB 2 388 614, which is incorporated herein by reference, illustrates an example of a spacer that may be used in this manner. The cavity wall spacer disclosed herein, comprises a novel configuration which provides various advantages which will be apparent from the description below.

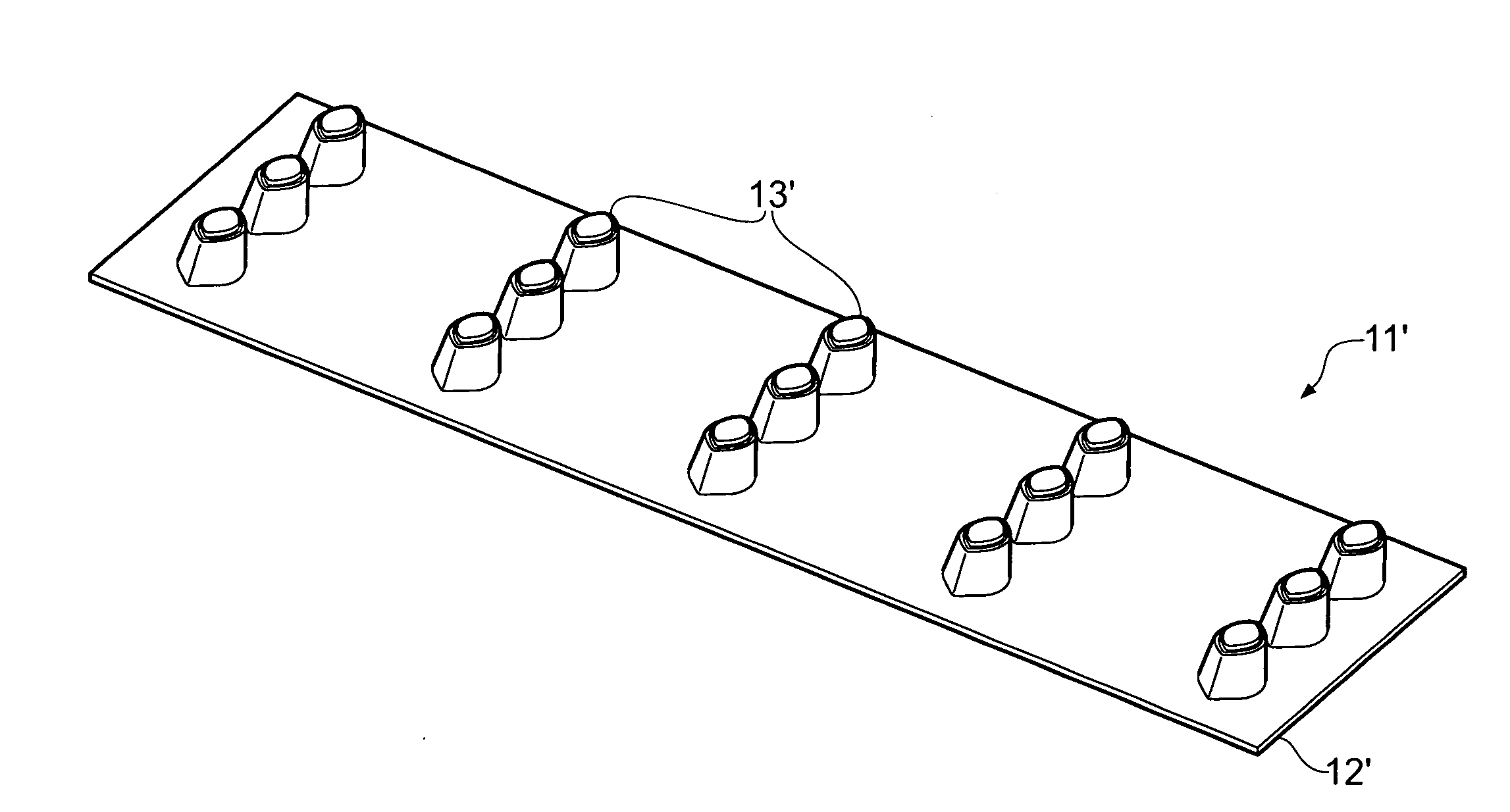

[0041]Referring to FIG. 1, there is shown a cavity wall spacer,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap