A nanofiber membrane filter material with antibacterial function and preparation method thereof

A nanofiber membrane and filter material technology, applied in the field of membrane separation, can solve the problems of complex preparation process, reduce membrane porosity, and complicated process, and achieve the effects of high fiber stacking density, improved antibacterial performance, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

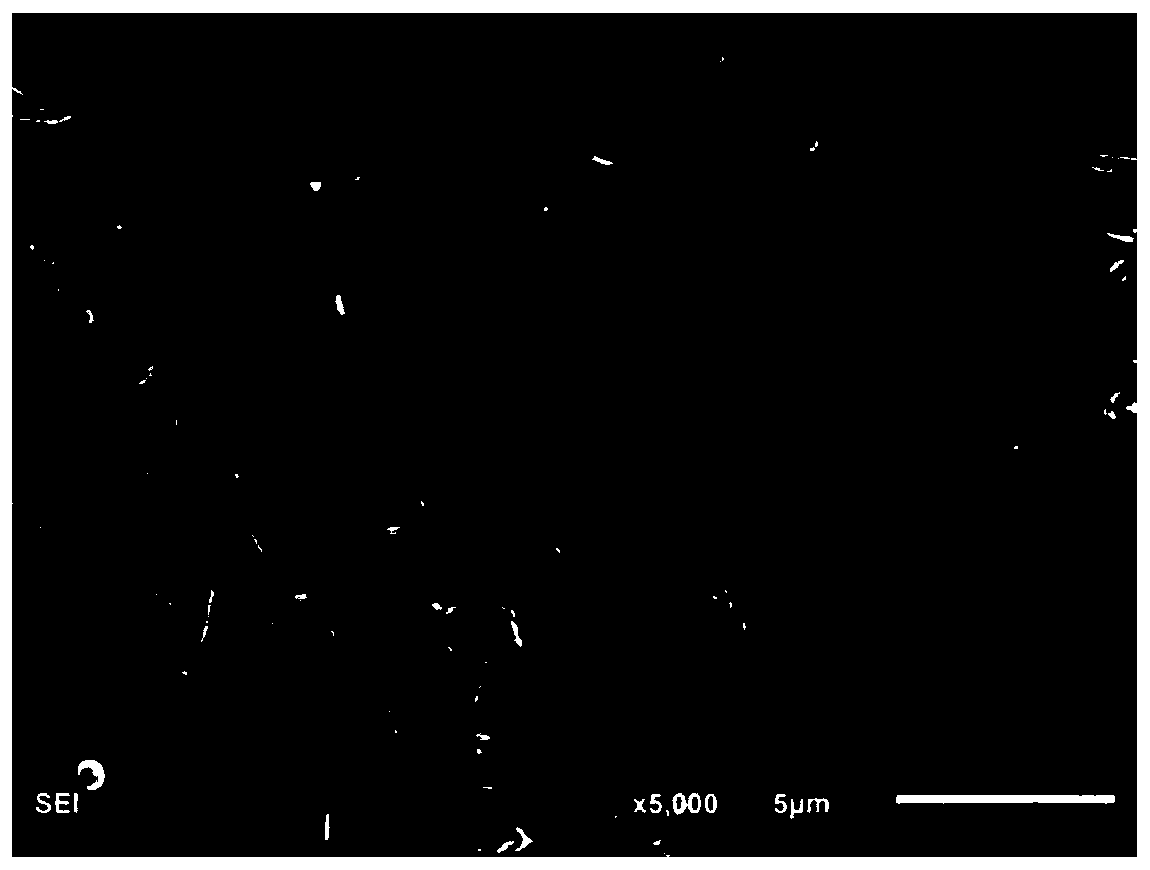

Image

Examples

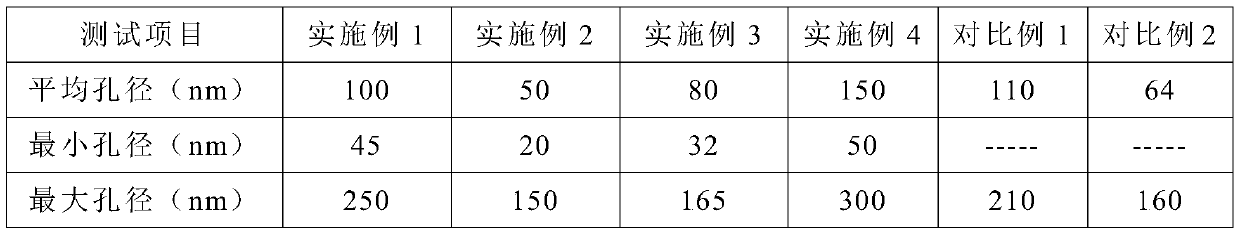

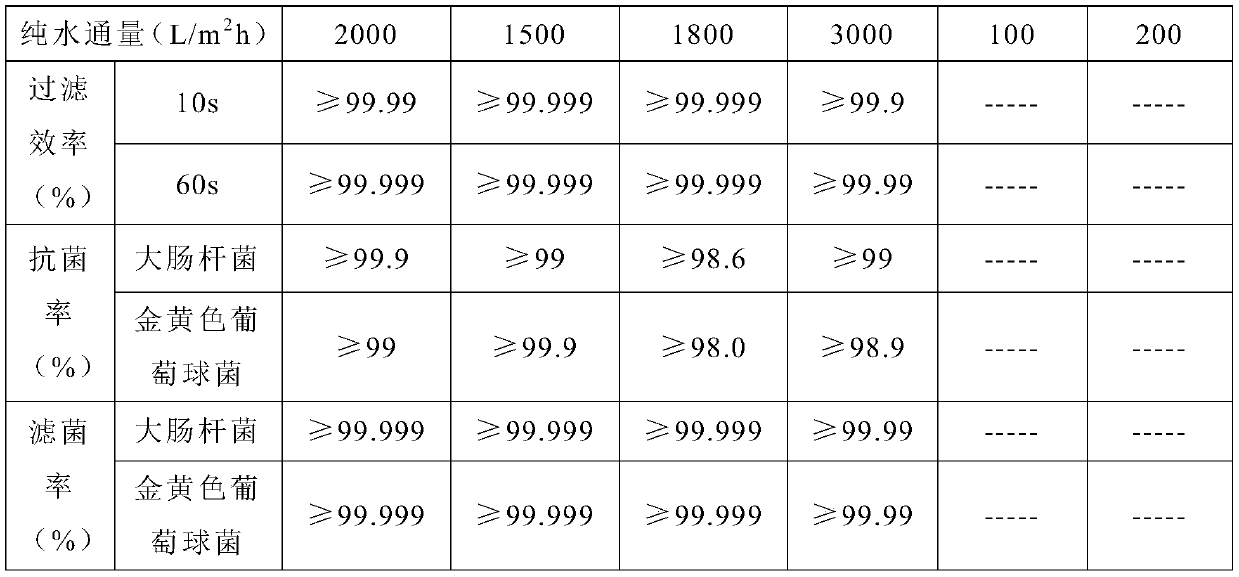

Embodiment 1

[0034] The invention discloses a preparation method of a nanofiber membrane filter material with antibacterial function, which comprises the following steps:

[0035] 1) Preparation of thermoplastic polymer nanofibers: the preparation steps are as follows:

[0036] 1.1) Preparation of thermoplastic polymer / cellulose acetate butyrate composite material: 1 kg of polyvinyl alcohol-ethylene copolymer (PVA-co-PE) and cellulose acetate butyrate (CAB) were uniformly mixed in a mass ratio of 2:3, Extrude and granulate in a twin-screw extruder with a processing temperature of 150°C to prepare a PVA-co-PE / CAB composite material;

[0037] 1.2) Preparing composite fibers: Spinning and drafting the PVA-co-PE / CAB composite material prepared in the step 1.1) through a melt spinning machine to obtain composite fibers;

[0038]1.3) Preparation of thermoplastic polymer nanofibers: reflux the composite fiber prepared in the step 1.2) in acetone, control the reflux temperature to 60° C., and ref...

Embodiment 2

[0044] The invention discloses a preparation method of a nanofiber membrane filter material with antibacterial function, which comprises the following steps:

[0045] 1) Preparation of thermoplastic polymer nanofibers: the preparation steps are as follows:

[0046] 1.1) Preparation of thermoplastic polymer / cellulose acetate butyrate composite material: 1 kg of polyethylene terephthalate (PET) and cellulose acetate butyrate (CAB) were uniformly mixed in a mass ratio of 3:7, and then processed Extrude and granulate in a twin-screw extruder at a temperature of 200°C to prepare a PET / CAB composite material;

[0047] 1.2) Preparing composite fibers: Spinning and drawing the PET / CAB composite material prepared in the step 1.1) through a melt spinning machine to obtain composite fibers;

[0048] 1.3) Preparation of thermoplastic polymer nanofibers: reflux the composite fibers prepared in the step 1.2) in acetone, control the reflux temperature to 60° C., and reflux time to 72 hours ...

Embodiment 3

[0054] The invention discloses a preparation method of a nanofiber membrane filter material with antibacterial function, which comprises the following steps:

[0055] 1) Preparation of thermoplastic polymer nanofibers: the preparation steps are as follows:

[0056] 1.1) Preparation of thermoplastic polymer / cellulose acetate butyrate composite material: 1 kg of polyamide (PA) and cellulose acetate butyrate (CAB) were uniformly mixed at a mass ratio of 1:3, and the processing temperature was 200 ° C in a twin-screw Extrude and granulate in the extruder to prepare PA / CAB composite material;

[0057] 1.2) Preparing composite fibers: Spinning and drawing the PA / CAB composite material prepared in the step 1.1) through a melt spinning machine to obtain composite fibers;

[0058] 1.3) Preparation of thermoplastic polymer nanofibers: reflux the composite fibers prepared in the step 1.2) in acetone, control the reflux temperature to 60° C., and reflux time to 72 hours to extract cellul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com