Chilling apparatus

a chilling apparatus and chilling technology, applied in the field of chilling apparatus, can solve the problems of insufficient ice in many situations, inability to contain easily without melting, and a long time, and achieve the effect of maintaining the beverage container substantially dry and quick and efficient manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

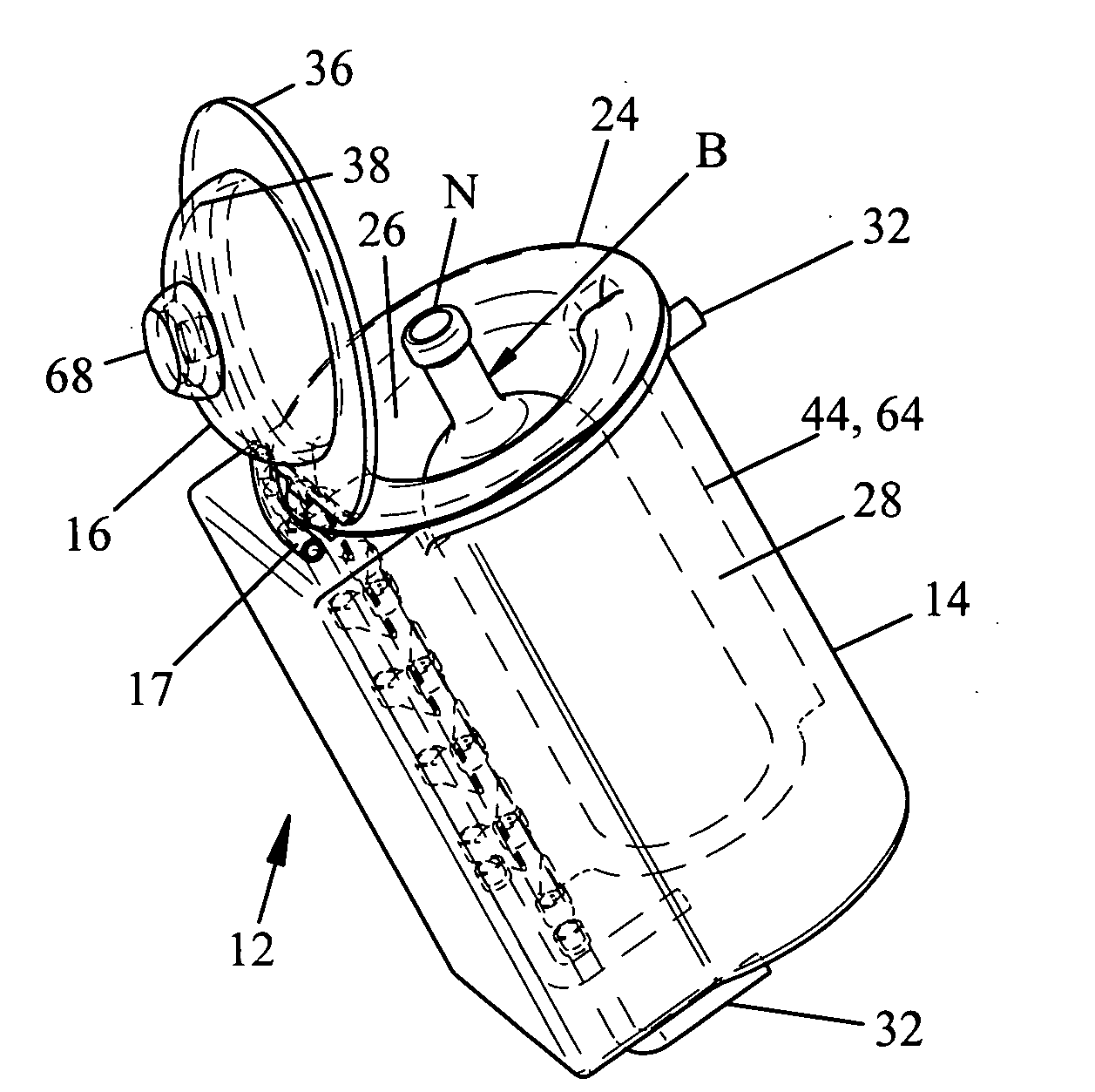

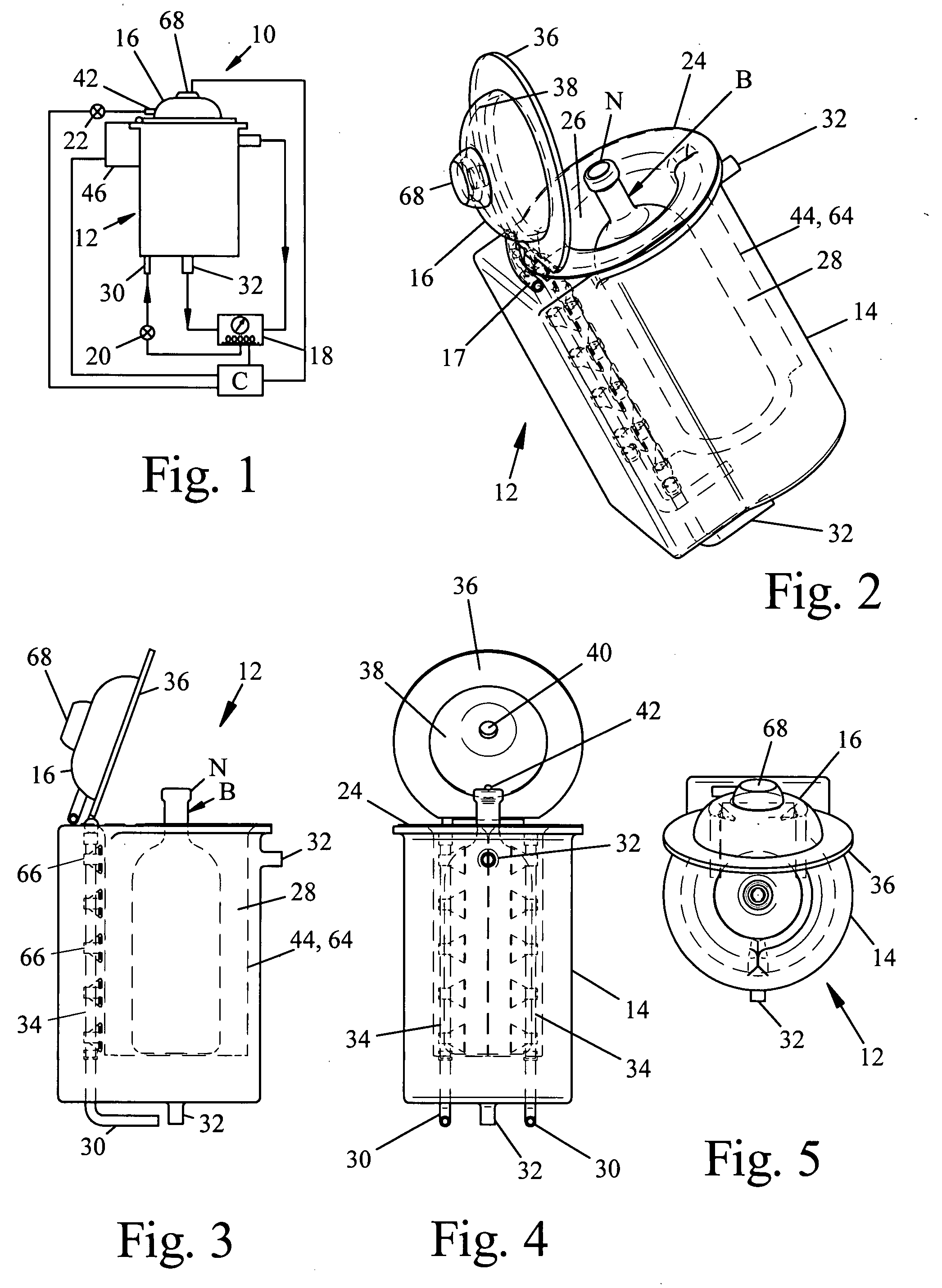

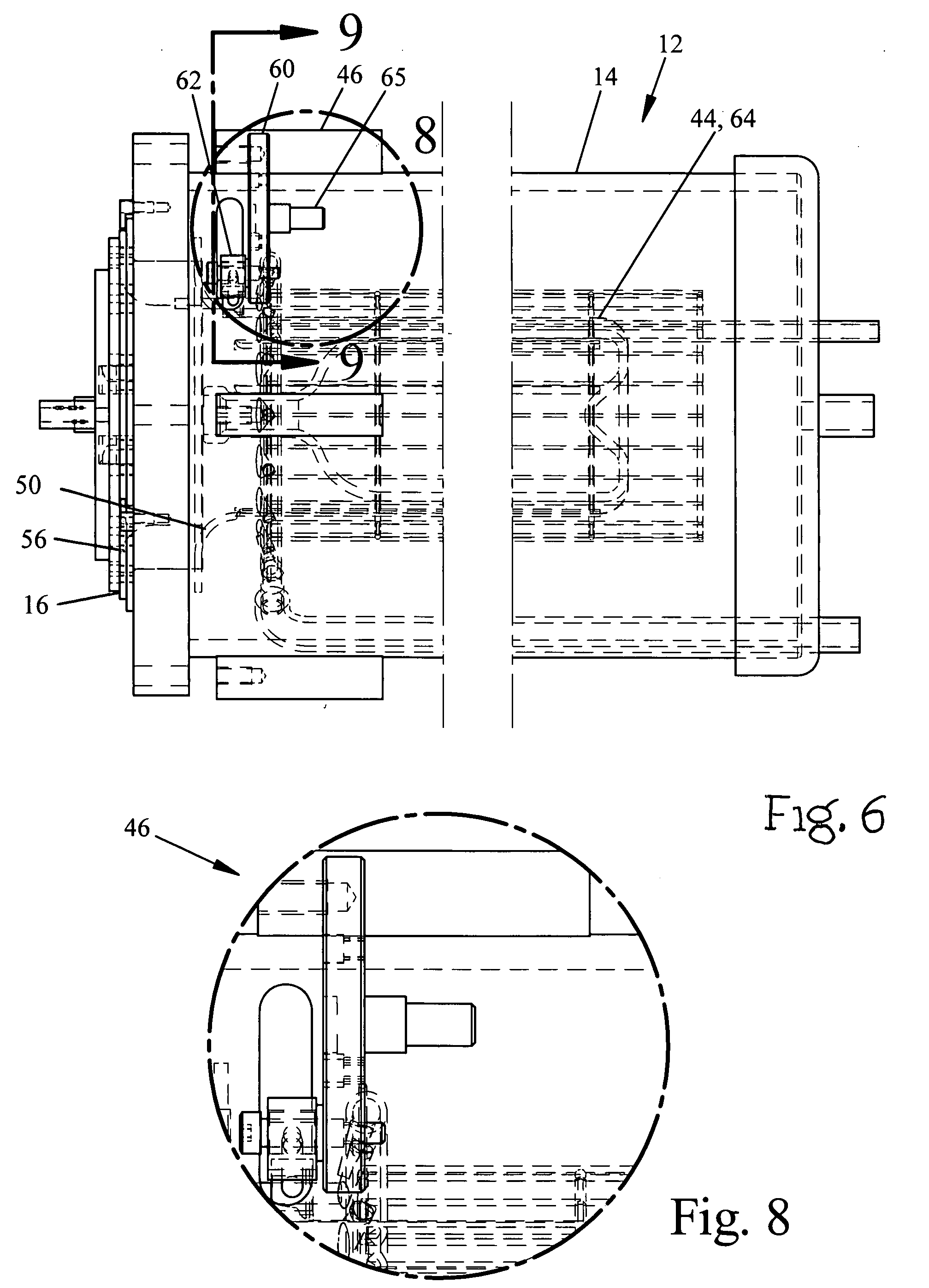

[0043]Turning now to the drawings, FIG. 1 illustrates an arrangement for cooling or chilling a beverage container, such as bottles or cans, and beverages to be cooled or chilled, such as beer, wine, soda, fruit juices and other fluids to be cooled. The arrangement for cooling is generally indicated by the reference number 10 and includes a cooling or chilling apparatus 12, which includes a chill housing 14 and closure lid 16, a refrigerator system 18 for chilling fluids, a fluid pump 20 in operable relation with the refrigerator system and the chill housing, and a vacuum pump 22 in operable relation with the closure lid 16. The interrelationship and operation of the above note elements will be described in greater detail herein below.

[0044]Importantly, not should be made that the chilling fluid is distributed via a closed loop circuit that prevents exposure of the chilling fluid to the atmosphere or to the product being chilled.

[0045]Turning to FIGS. 2-5 and 10, the chill housing 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com