Flush Mount Panels With Interconnects

a technology of interconnection and flush mount, which is applied in the direction of transducer casings/cabinets/supports, loudspeakers, electrical transducers, etc., can solve the problems of ineffective attaching components in other positions than along the ceiling joist, difficult to line up or evenly space multiple components, and large amount of work in taking measurements and making minor adjustments, etc. , to prevent cracking and fraying, cost-effective fabrication of devices, and small tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

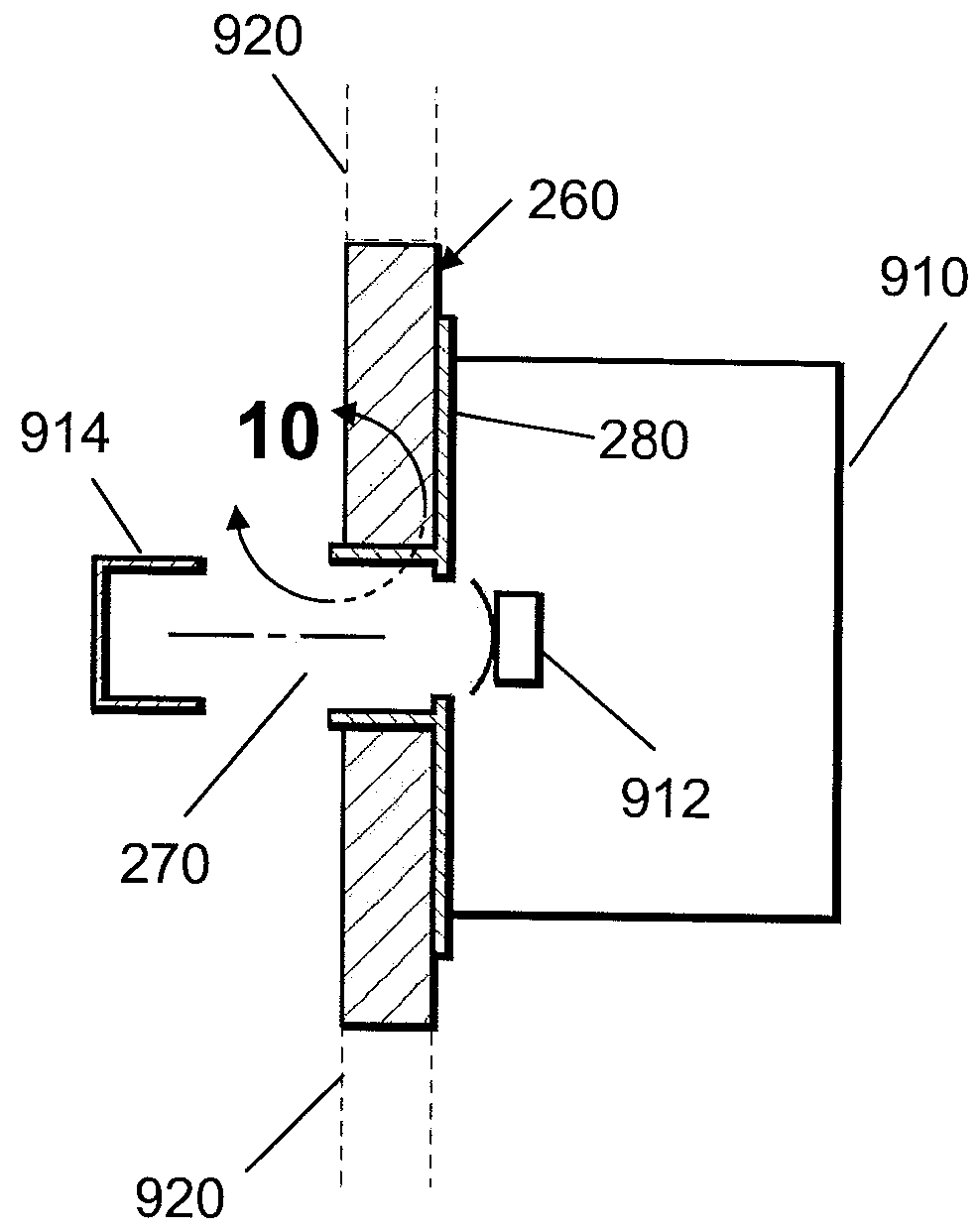

[0051]In FIG. 2 a component mounting apparatus 200 generally includes a panel 210, with opening 220 and panel 260 with opening 270. It should be appreciated that while each bracket is sized and dimensioned to hold a specific component, the brackets could be identical to one another to create a “universal bracketing system” that can hold components of various sizes.

[0052]Panel 210 and panel 260 are preferably substantially identical to one another in terms of shape, size, dimensions, and material, but can vary from one another without departing from the scope of the previous invention. Where the specification refers to only one panel in a figure, it is to be assumed that the other panel in the figure has the same features, unless otherwise stated.

[0053]Panel 210 is a piece of gypsum board, wood, plastic, or other material (or combination of materials) sufficiently strong to support a speaker or other desired component between two studs of a wall, or joists in a ceiling, or other supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com