Vacuum thermal insulation with inflatable load-carrying structure

a technology of vacuum insulation and load-carrying structure, which is applied in the direction of insulation improvement, packaging goods, paper/cardboard containers, etc., can solve the problem that the atmospheric pressure tends to scrunch the vacuum container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

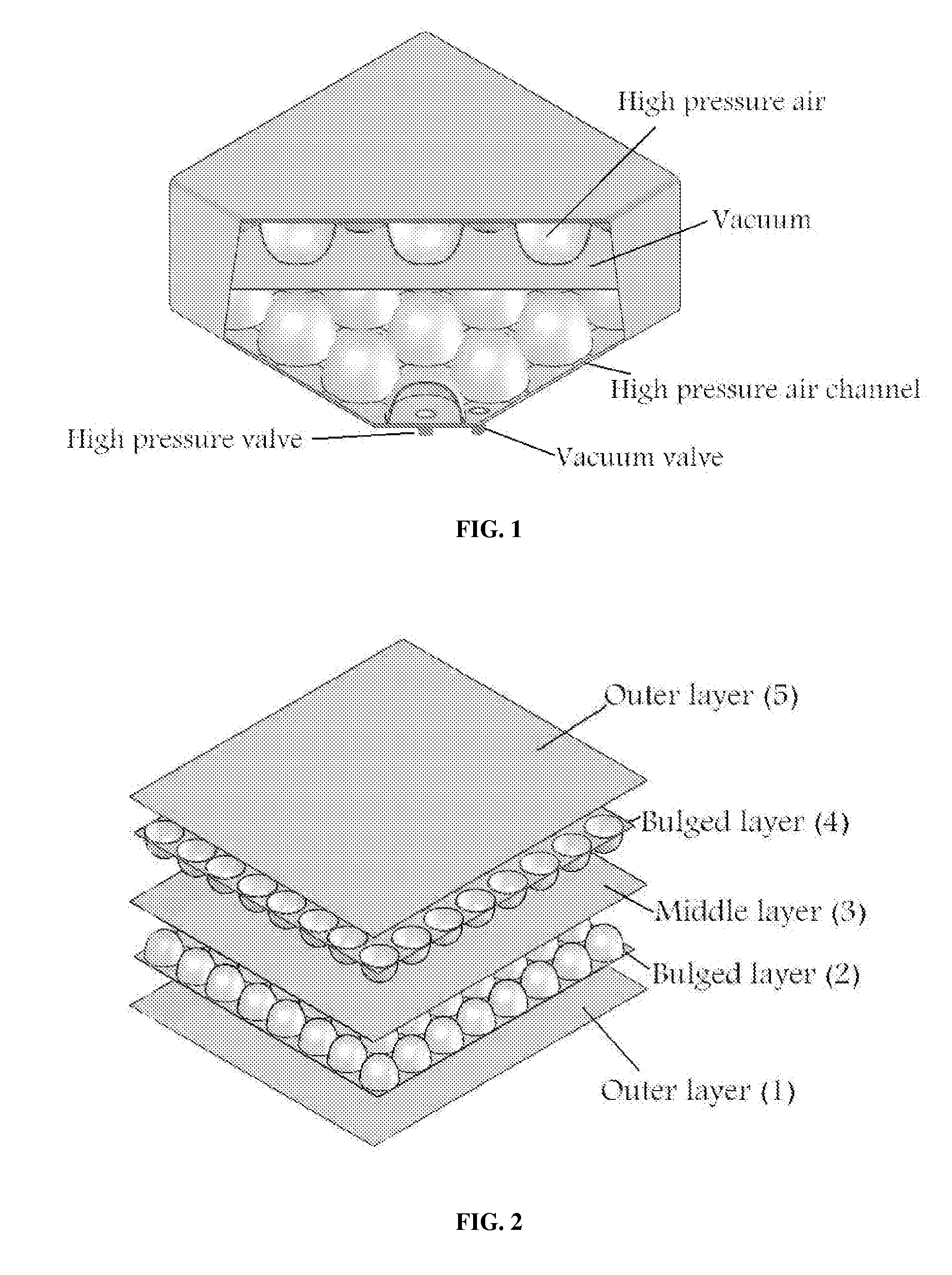

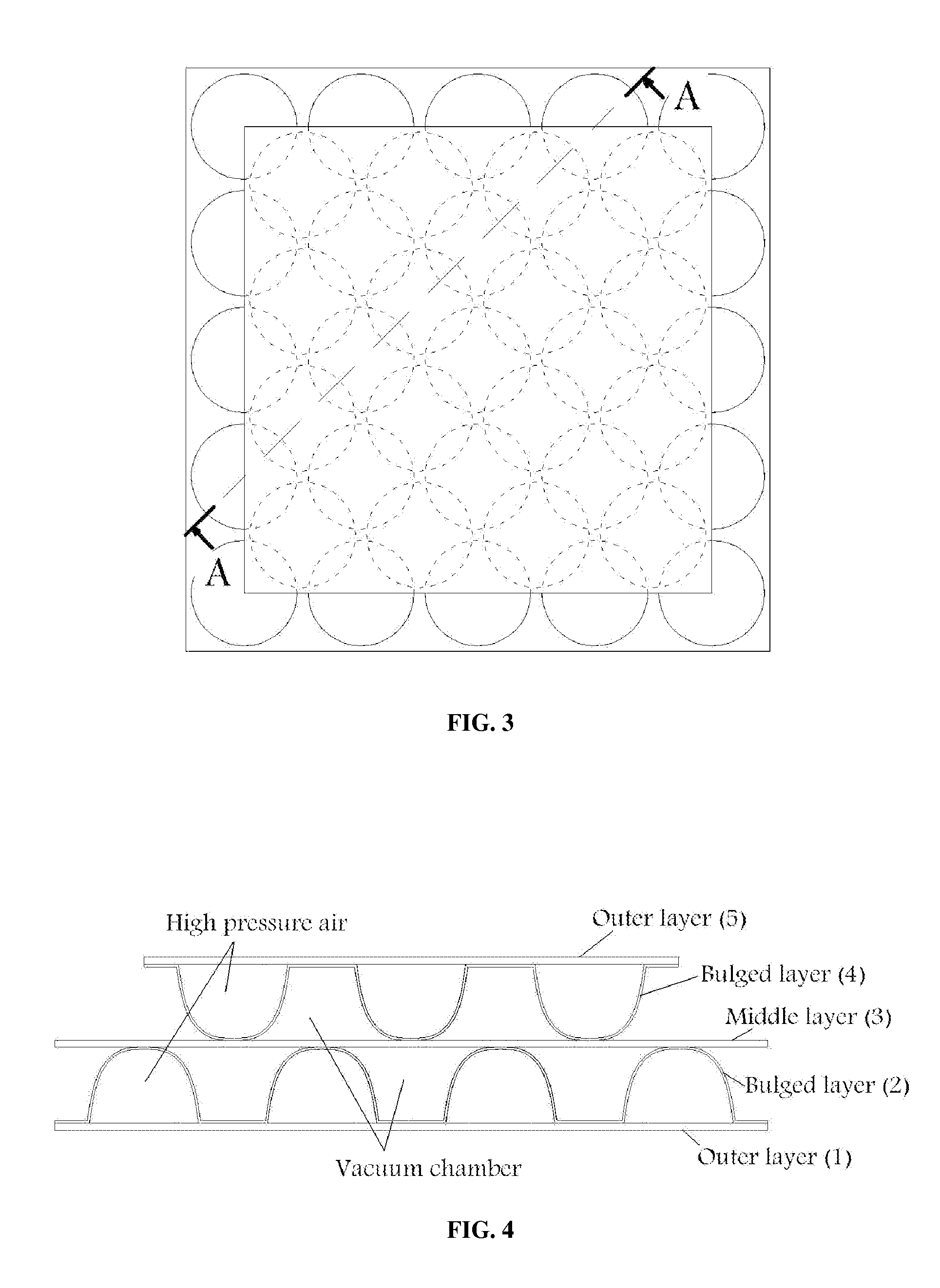

[0029]It is well known that in vacuum insulations the insulating effect will depend upon the extent of the vacuum, as well as the configuration of the remainder of the structure, including the amount of continuous structural contact between the opposing surfaces. Such structural contact will result in heat conduction between the surfaces. The proposed insulation is analyzed to investigate the effect of such parameters on thermal characteristics. Also the state of stress in the structure under the atmospheric and inside pressure loading is studied.

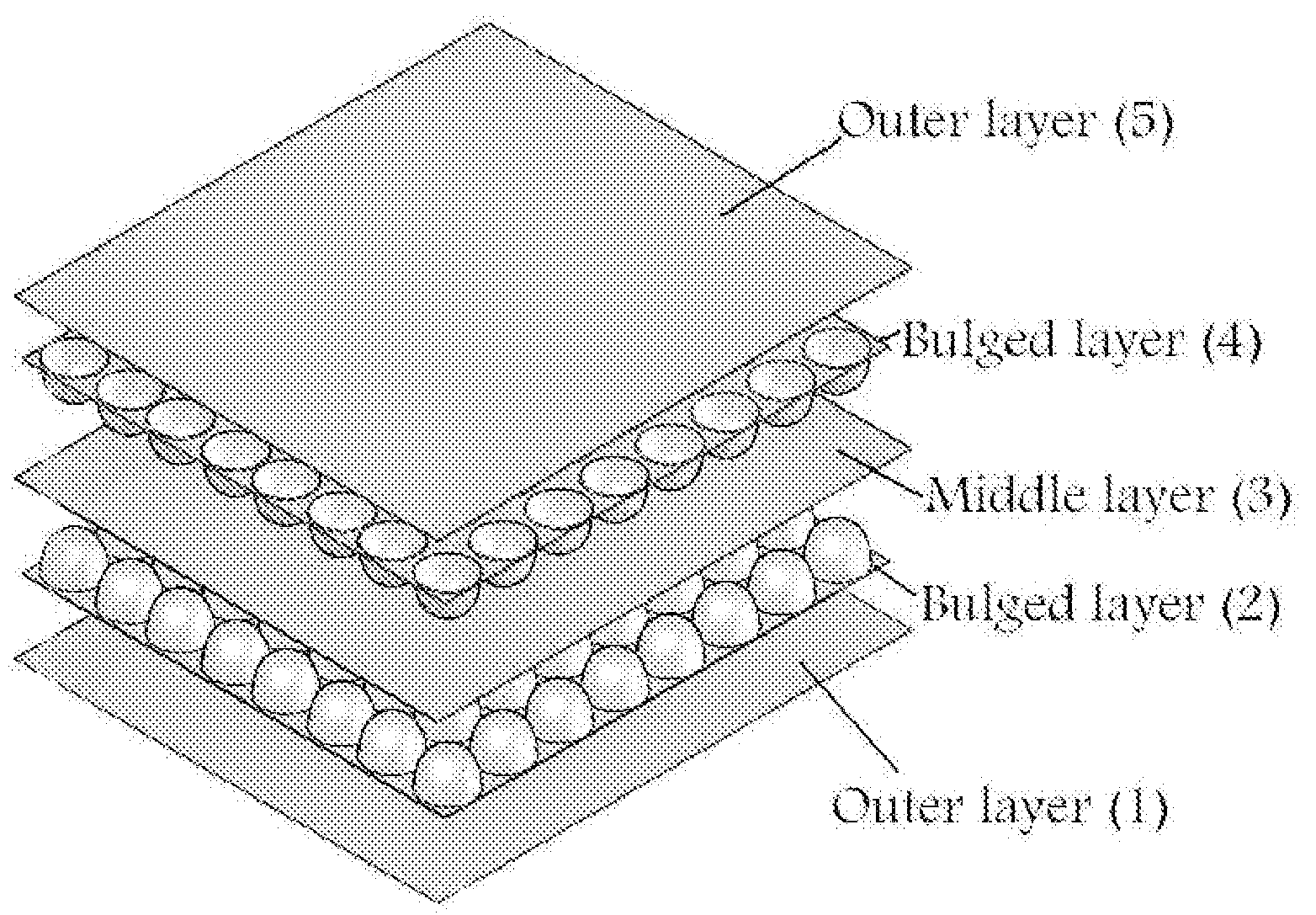

[0030]In the proposed insulation, bulges are main parts of the load-carrying structure. The bulges' area to total area determines the required inside pressure of structure to inflate the insulation. This ratio is the main parameter affecting the thermal efficiency of insulation. In other words the greater inside pressure of structure leads to a smaller required bulge area, which yields to a greater vacuum area and theref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com