Bolt fastening method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

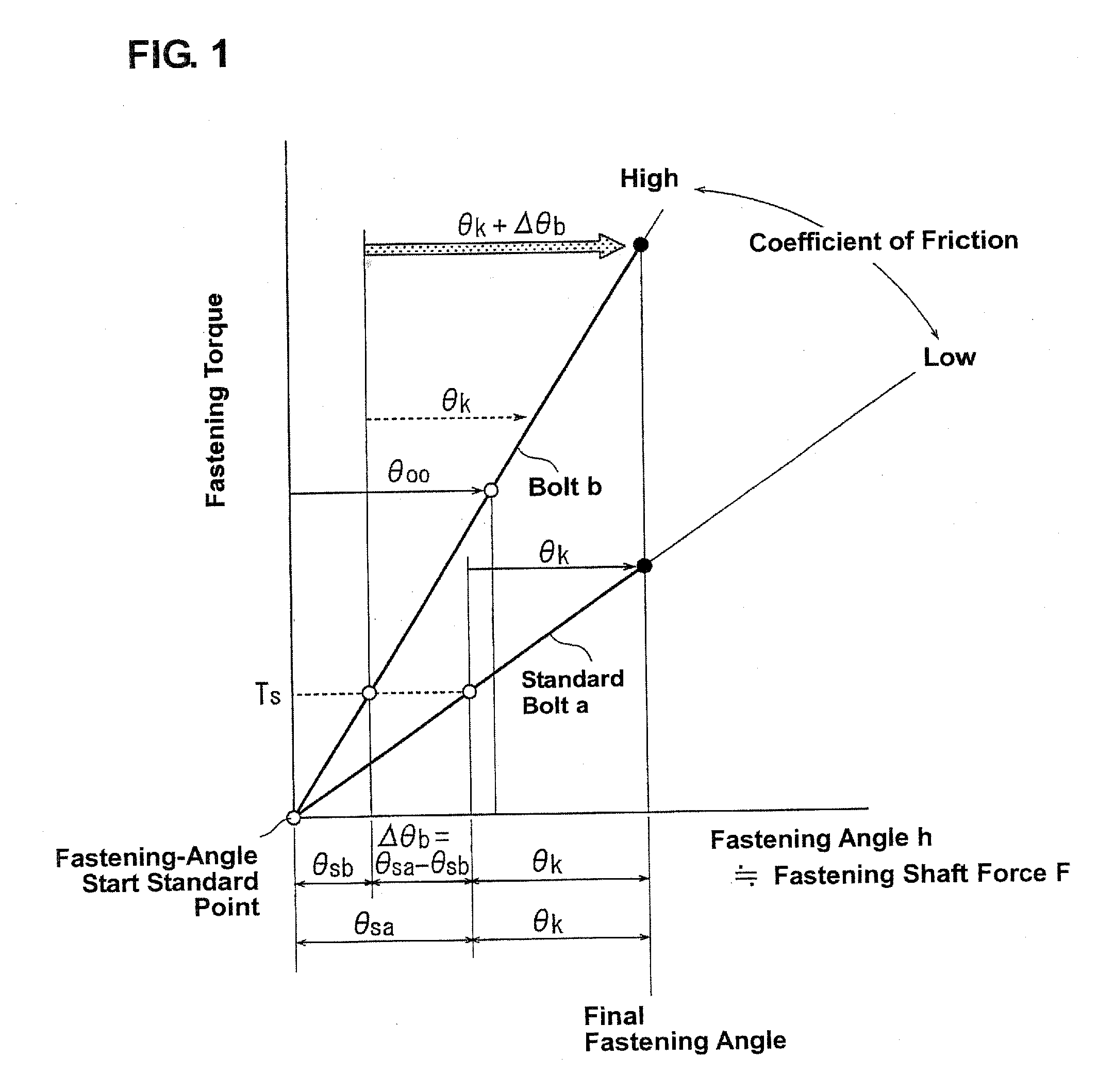

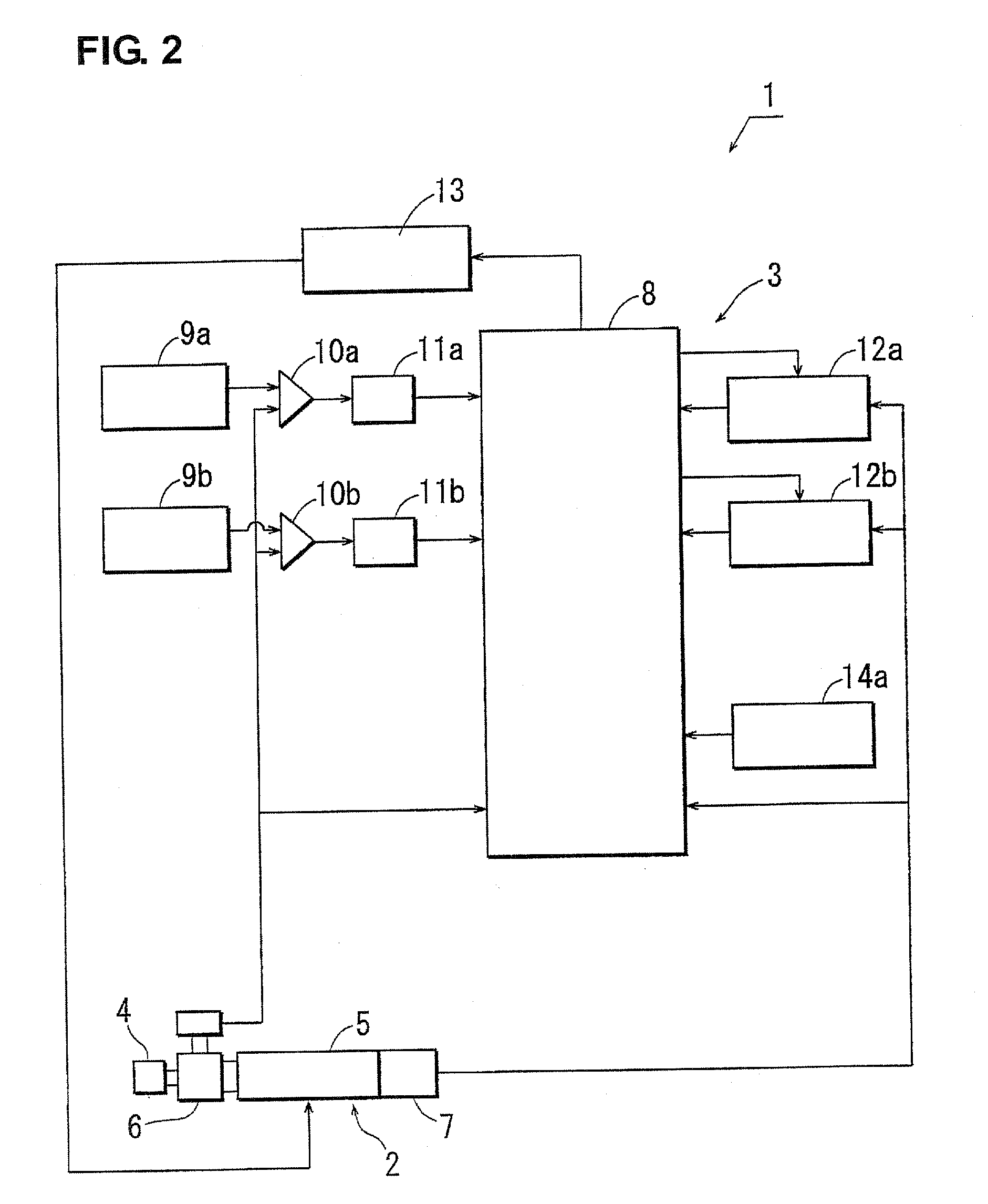

[0032]77A bolt fastening method according to a first embodiment will be described

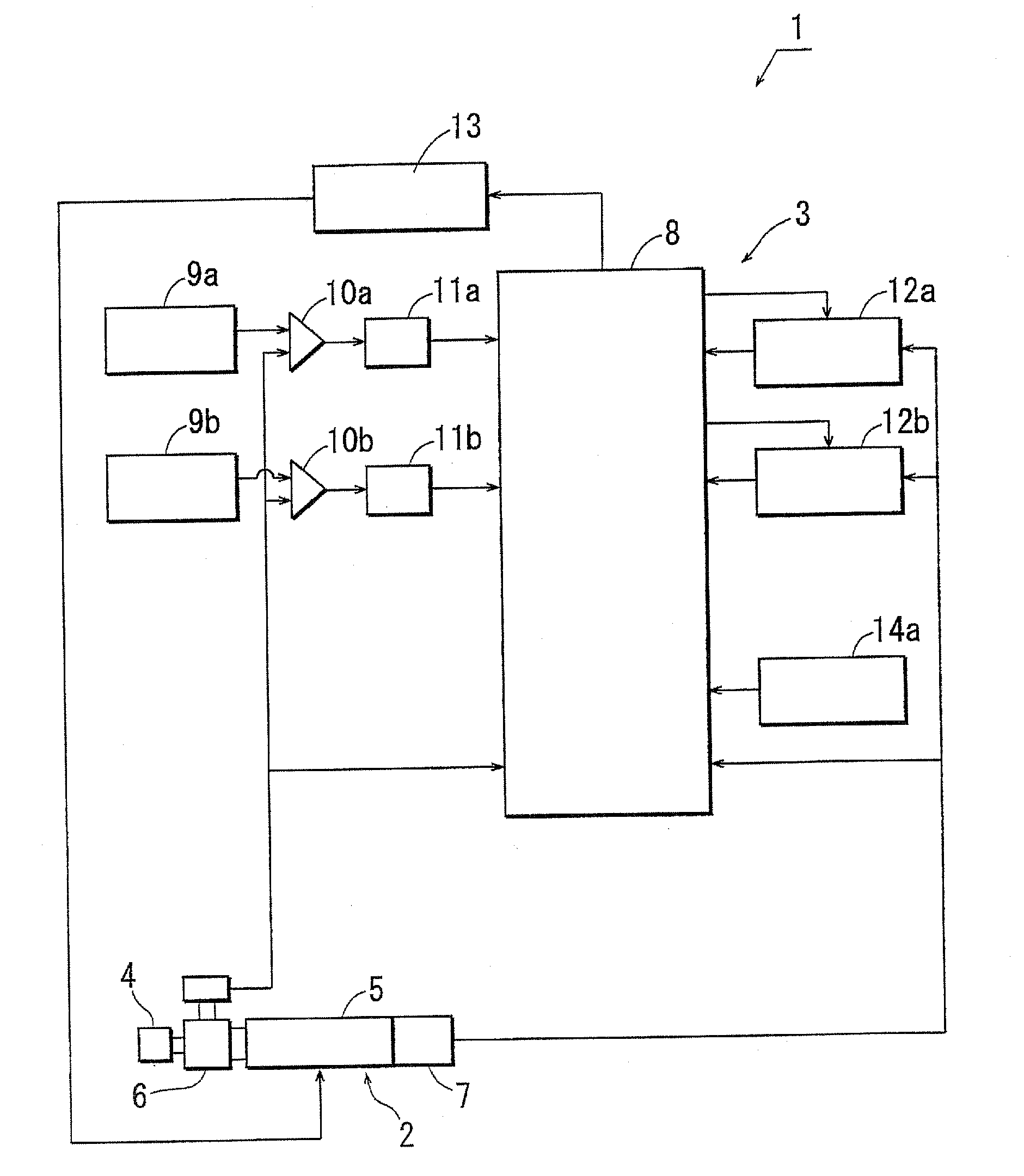

[0033][1] In a bolt fastening method according to the first embodiment, the bolt is fastened to a fastened member (engine bearing parts, for example) with a bolt rotating device such as a nut runner, and a fastened member is fastened with the bolt. Herein, the bolt is fastened up to a predetermined snug torque Ts and then the bolt is further fastened by a specified angle from a bolt angle corresponding to the snug torque Ts (torque+angle method). If the torque method (the method of managing bolt fastening with the fastening torque which utilizes the proportional relationship between the fastening torque and the fastening shaft force (in the elasticity area of bolt)), which is shown in FIG. 11, was applied, the fastening shaft force of the bolt would varies improperly according to the coefficient of friction between the screw face and the seat face of the bolt. The torque+angle method, however, uses addi...

embodiment 2

[0063]Hereinafter, a bolt fastening method according to a second embodiment will be described. Herein, like the above-described first embodiment, the torque+angle method is applied in which the difference Δθ, and the addition of this difference Δθb to the base angle θk is set as the new specified angle. According to the bolt fastening method according to the second embodiment, however, the fastening angles of a plurality of bolts to be fastened at the point where the fastening torque of each bolt has reached the snug torque Ts are detected, an average angle θave of the obtained fastening angles of the plurality of bolts is obtained, and the average angle θave is used as the standard angle. Thereby, the correction of the fastening shaft force of the bolts can be properly achieved regardless of presence of the plural bolts to be fastened, so that the fastening shaft forces of the plural bolts can be made uniform. In this case, part of all of the bolts which are to be fastened can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com