Electrically powered well servicing rigs

a technology of electric motors and wells, which is applied in the direction of wellbore/well accessories, drilling pipes, hoisting equipment, etc., can solve the problems of apparatuses, and affecting the operation and maintenance of hydraulically-powered motors. , to achieve the effect of reducing or eliminating the leakage of hydraulic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

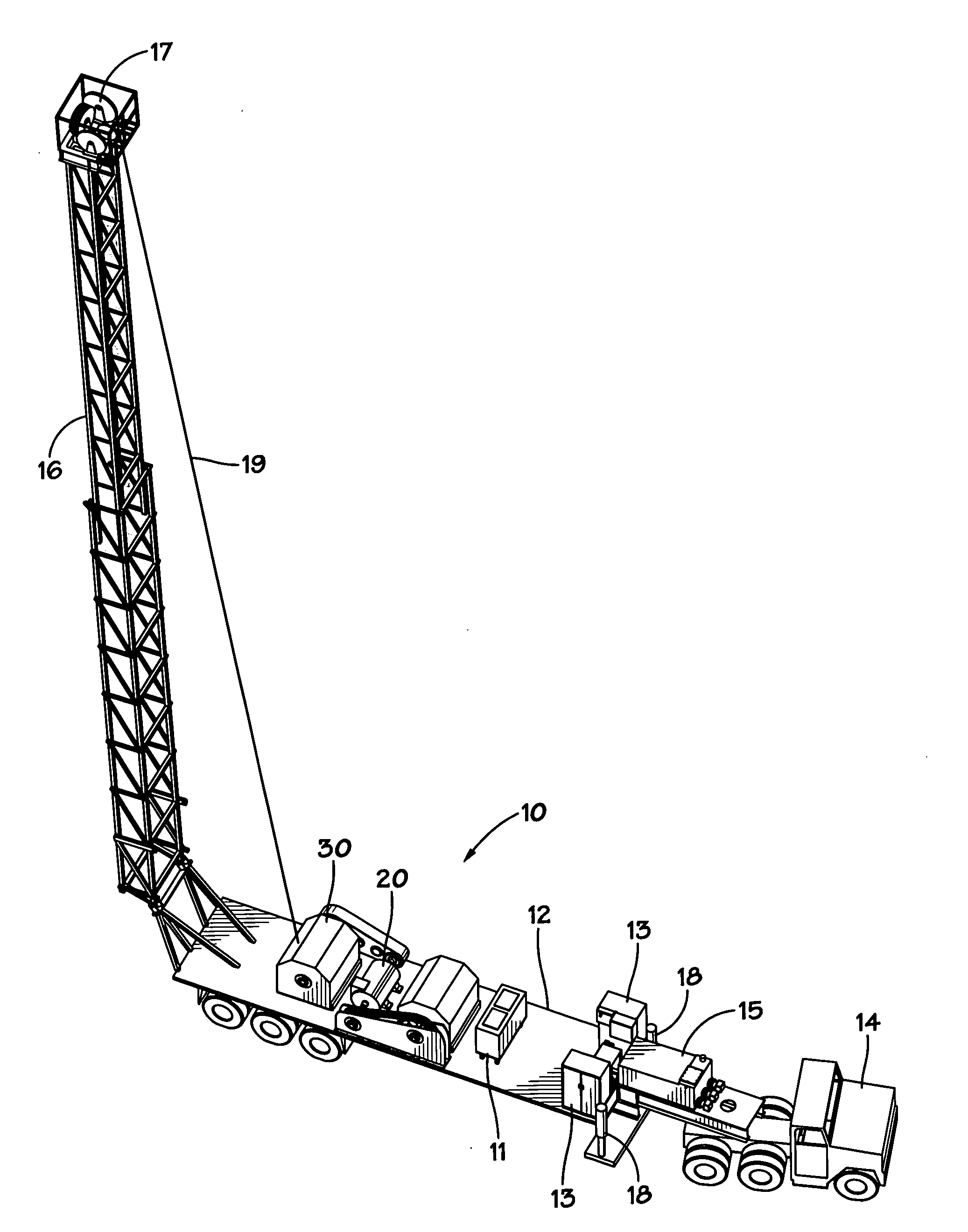

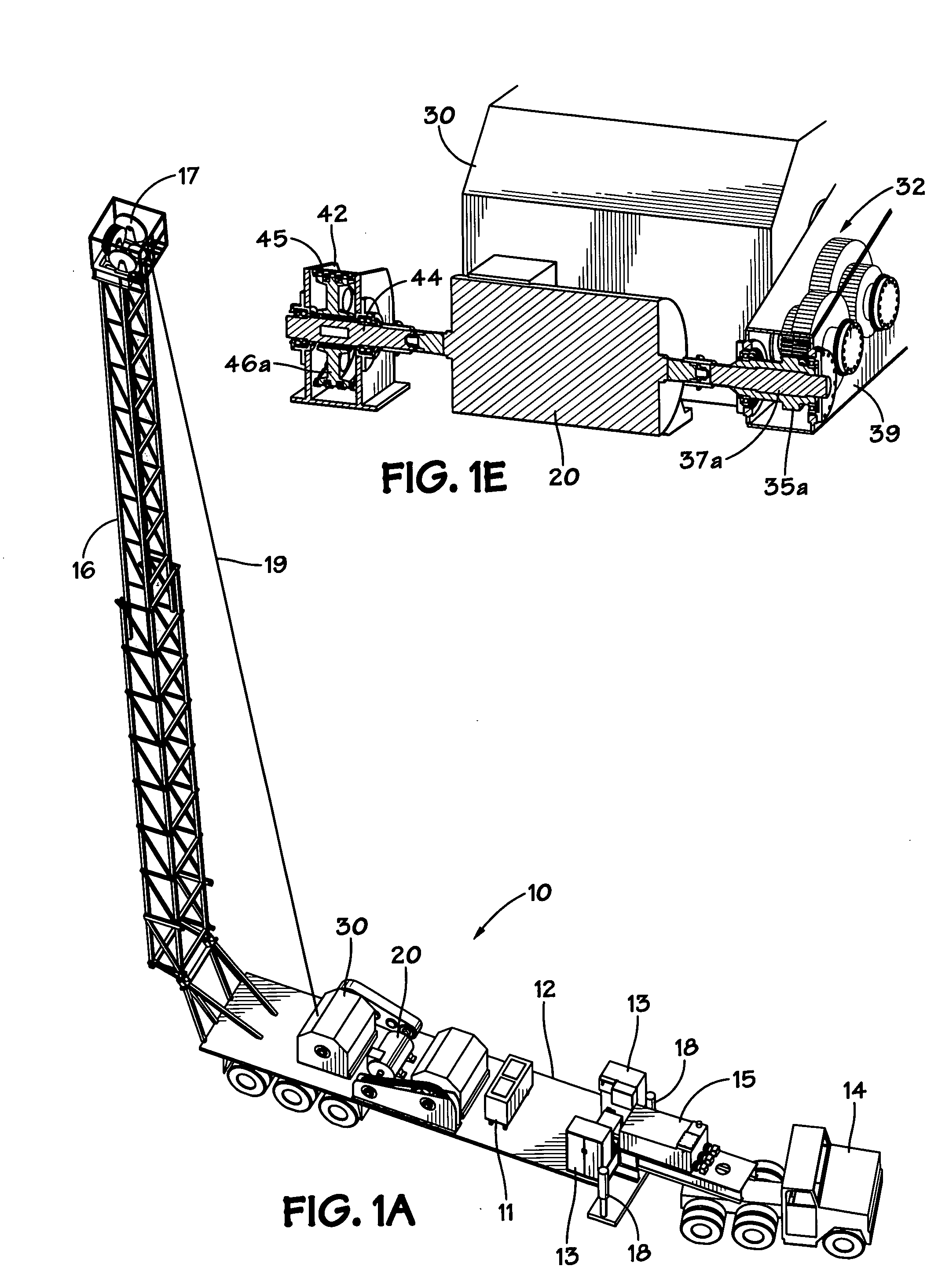

[0047]FIGS. 1A-1G show a system 10 according to the present invention which includes a vehicle with a trailer 12 moved by a truck 14 and a mast 16 which can be raised from the trailer 12 to an erected position as shown in FIG. 1A. Levelling jacks 18 support the trailer 12. Optionally, no separate truck is used and the rig is self-propelled.

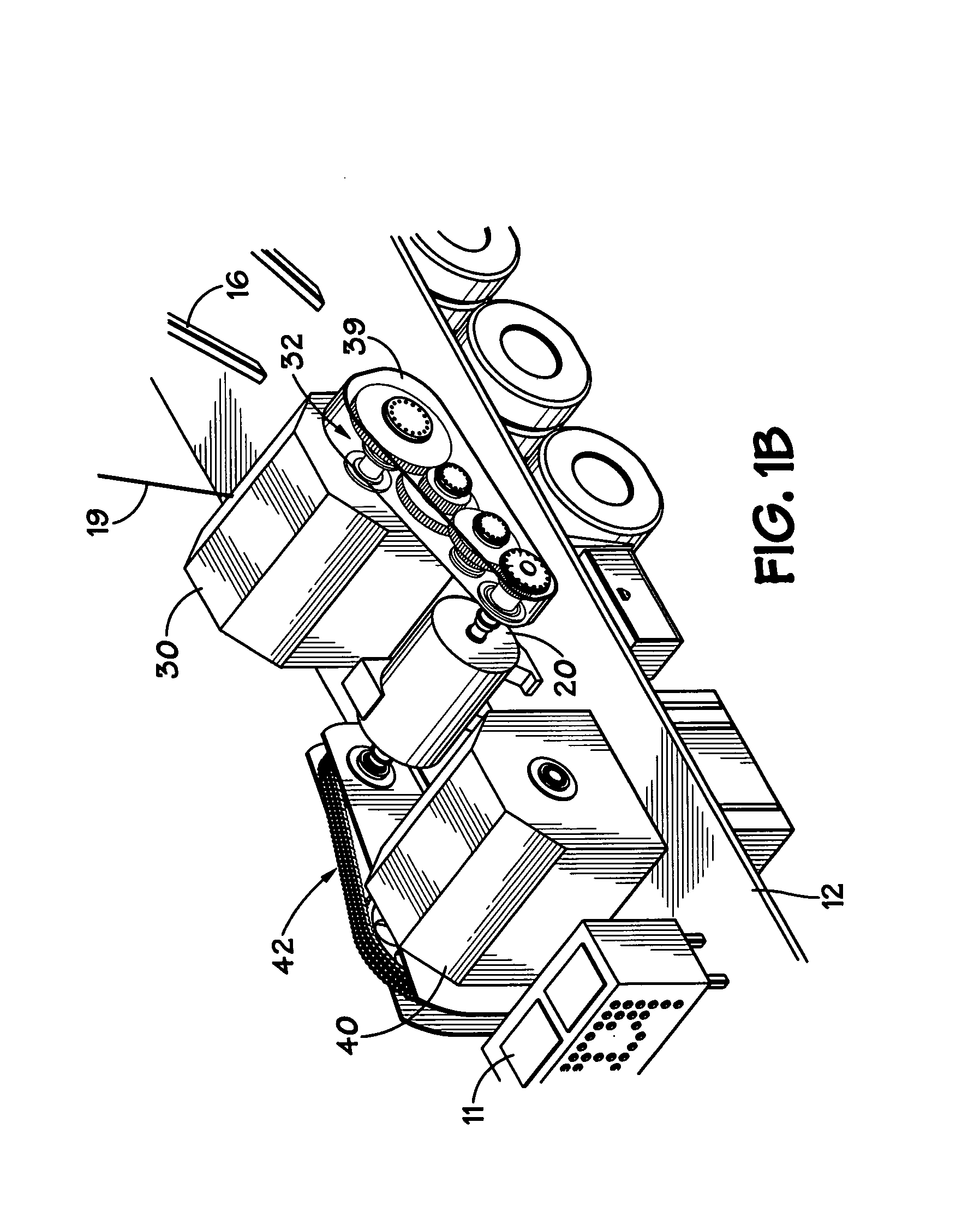

[0048]An electric motor 20 provides power to operate a main winch 30 (also called a drawworks) and a sandline winch 40. The motor 20 has two drive shafts, with one shaft extending from each end of the motor. One drive shaft 21 drives the main drum winch 30 via a gear system 32. Optionally, a chain drive system is used. Another drive shaft 22 drives the sandline winch via a chain drive system 42. A shiftable cutout coupling 23 selectively couples the drive shaft 21 to a shaft 37a of the gear system 32. A housing 39 encloses the gears and shafts.

[0049]A shiftable cutout coupling 24 selectively couples the drive shaft 22 to a shaft 44 of the chain dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com