In-Furnace Gas Injection Port

a gas injection port and furnace technology, applied in the direction of lighting and heating apparatus, combustion types, and lump and pulverizing fuel, can solve the problems of increased cost and weight, increased and ineffective prevention of ash adhesion or growth of clinker, etc., to achieve high reliability and fuel combustion. high, the effect of reducing nox and co combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

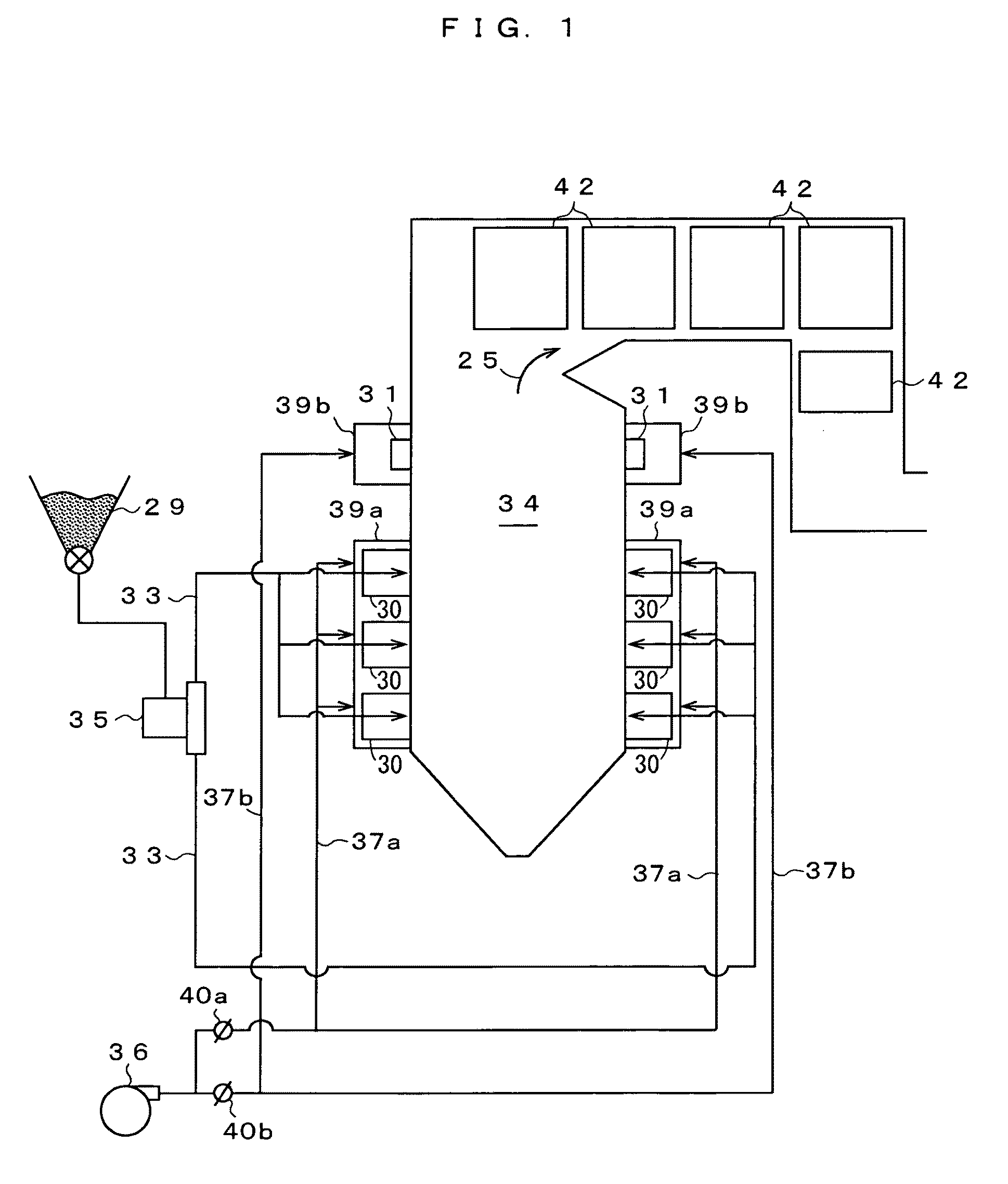

[0067]Next, an explanation will be made for aspects of the after airport (hereinafter referred to as “port” or “AAP”) 31 applied to the boiler furnace 34 by referring to the following embodiments.

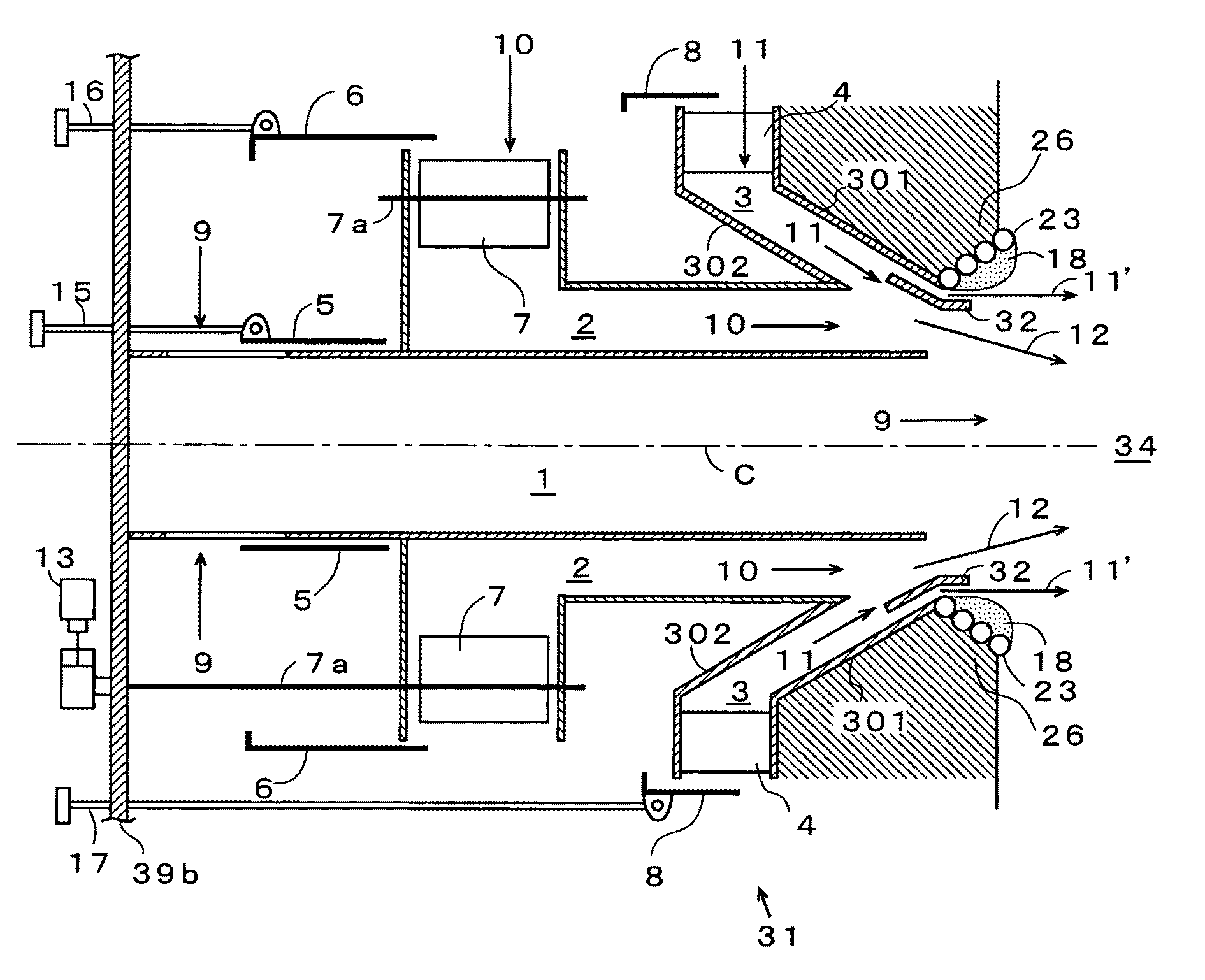

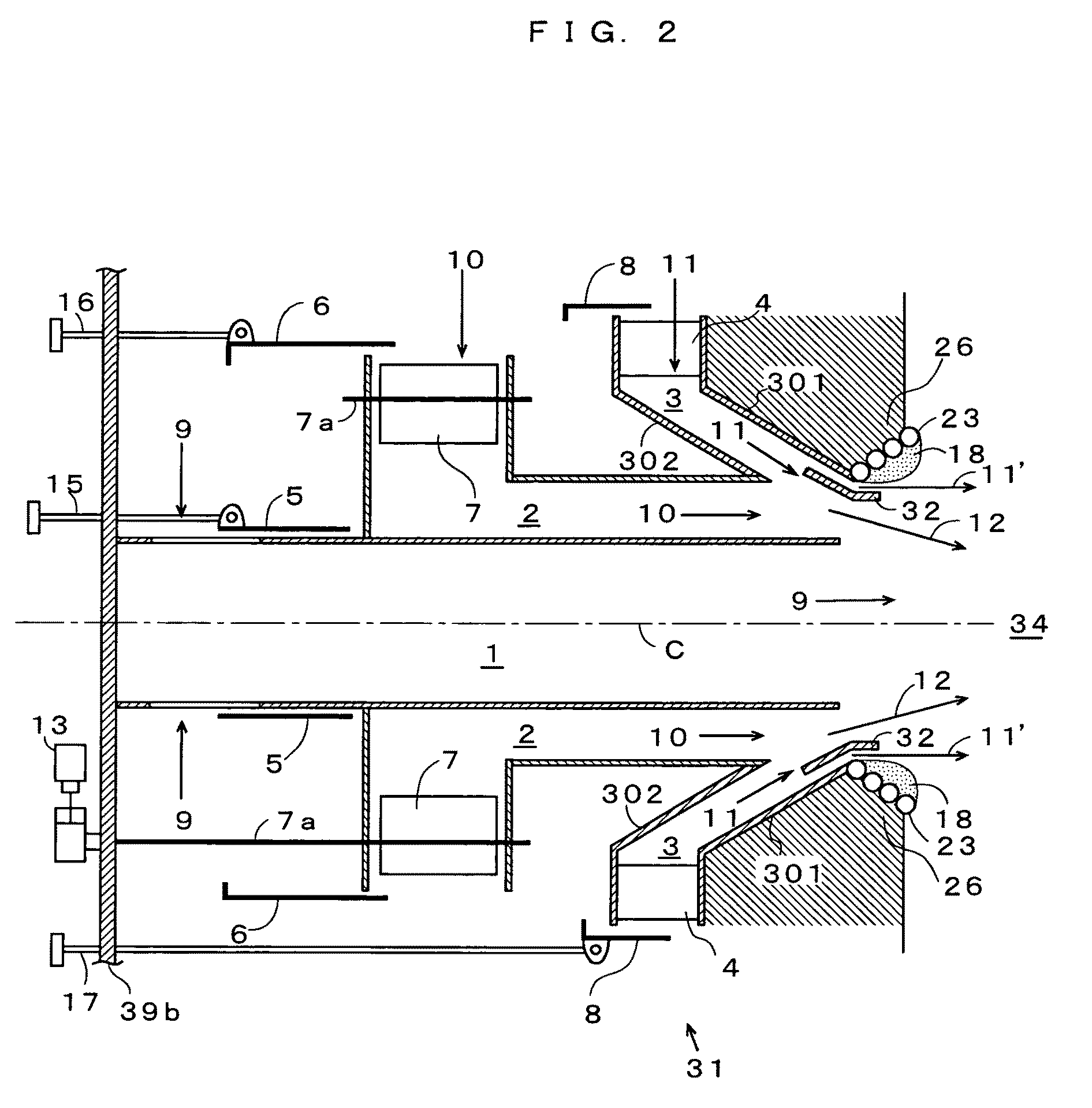

[0068]FIG. 2 is a sectional view of the port 31 in the present embodiment (a sectional view taken along line A-A′ in FIG. 4). FIG. 3 is a perspective view in which the port 31 is partially omitted. FIG. 4 is a drawing of the port 31 which is viewed from the furnace 34 side.

[0069]The port 31 is arranged inside the window box 39b, and the air nozzle mechanism thereof is provided with a primary nozzle 1, a secondary nozzle 2 for injecting air of rotating flow along the outer circumference of the primary nozzle 1 as secondary air 10 and a tertiary nozzle 3 for injecting air of flow heading from the outside of the primary nozzle 1 to the central axis C of the port 31 as tertiary air 11.

[0070]The primary nozzle 1, the secondary nozzle 2 and the tertiary nozzle 3 are of a coaxial nozzle structure....

embodiment 2

[0086]FIG. 8 shows a sectional view of the port 31 of Embodiment 2. Additionally, FIG. 9 and FIG. 10 are schematic diagrams of the port 31, which is a comparative example for comparison with the port 31 of Embodiment 2 given in FIG. 8.

[0087]As the port shown in FIG. 8, the primary nozzle 1, the secondary nozzle 2 and the tertiary nozzle 3 are shown, through which the primary air, the secondary air and the tertiary air flow respectively in a concentric manner. At least such a structure is acceptable that a flow from the outer circumference of the tertiary nozzle 3 in the present embodiment toward the central axis C of the port is increased and allowed to flow through a port opening of the furnace 34 (throat wall 26), thereby the air injection flow is able to appropriately form a so-called contracted flow. In other words, the primary nozzle 1 and the secondary nozzle 2 are not essential in forming the so-called contracted flow.

[0088]Air flowing through the primary nozzle 1, which is a...

embodiment 3

[0110]FIG. 11 is a schematic diagram of the port 31 showing the present embodiment 3. In the constitution given in FIG. 11, the same parts as those of the constitution given in FIG. 8 are given the same numerals or symbols, an explanation of which will be omitted here.

[0111]In the present embodiment, a parallel portion 26a which is constant in cross section of the channel and parallel to the central axis C is provided on the throat wall 26 of enlarged pipe configuration of the port 31. Further, a cylindrical portion 32a running along the parallel portion 26a is also provided on the louver 32. Additionally, the contracted flow from the tertiary nozzle 3 partially flows into a space between the louver 32 and the throat wall 26 of enlarged pipe configuration, a flow 11′, or a part of the tertiary air 11 which seals the surface of the throat wall 26 of the furnace 34, flows effectively in the vicinity of the wall surface of the throat wall 26, thus making it possible to eliminate a nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com