Electrochemical sensor

a technology of electrochemical sensor and electrode, applied in the field of electrochemical sensor, can solve the problems of limited research on high pressure and high temperature electrochemistry, limited use of commercially available press-fit electrodes, and problems in the application of previously suggested electrode manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

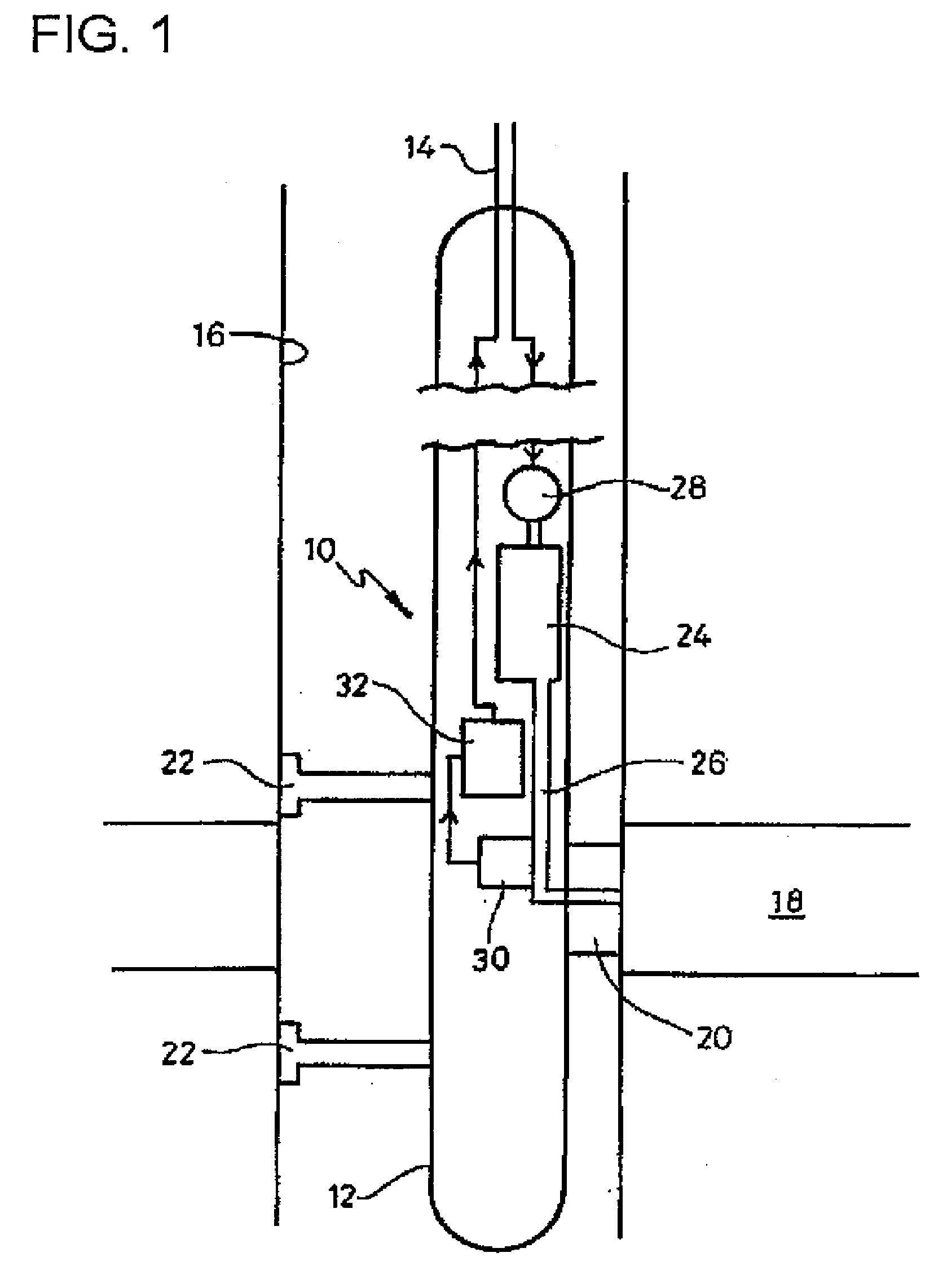

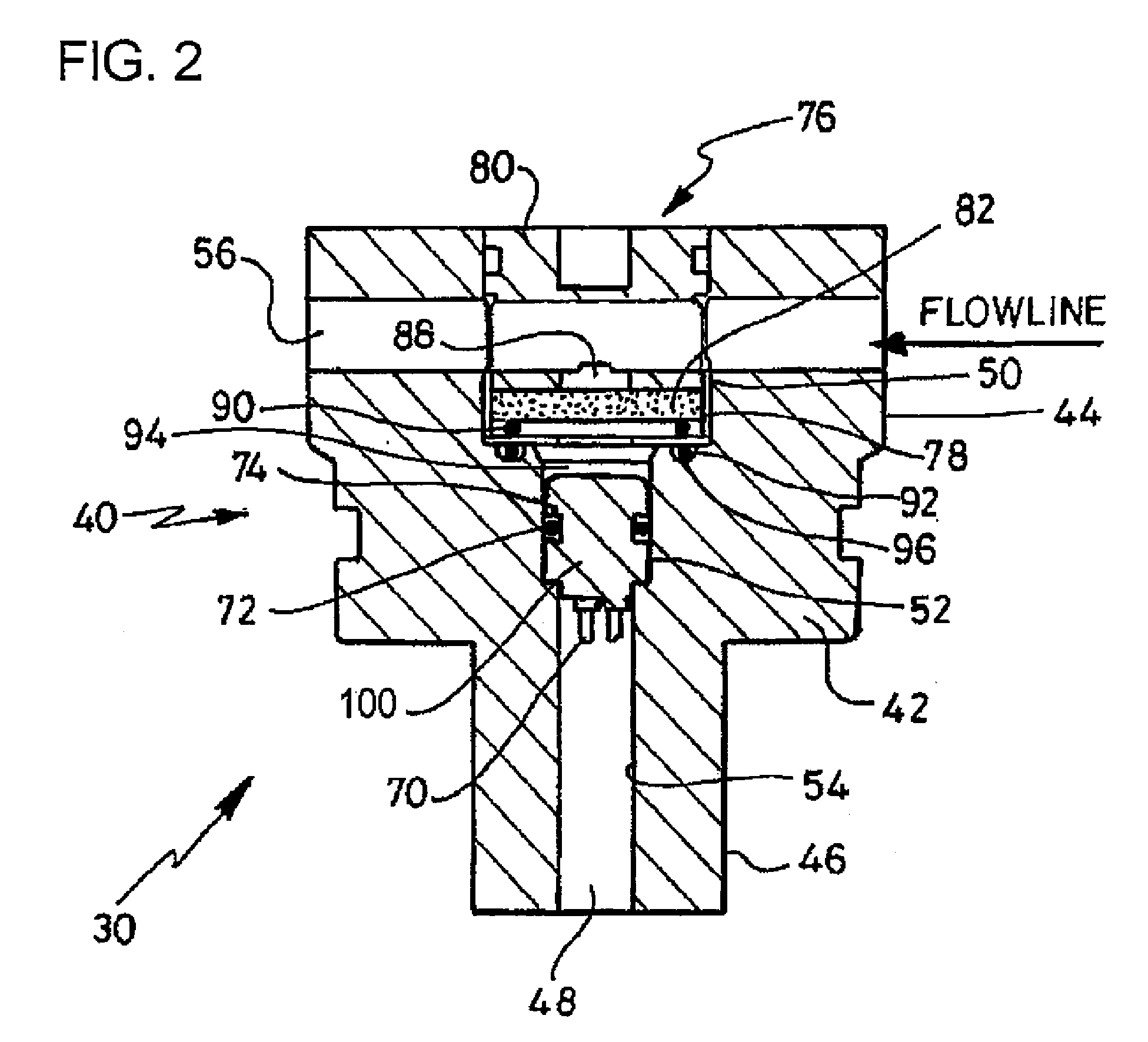

[0027]The invention will be now described with reference to illustrative embodiments. Those skilled in the art will recognize that many alternative embodiments can be accomplished using the teachings of the present invention and that the invention is not limited to the embodiments illustrated for explanatory purposes.

[0028]It is to be noted that, in the explanation of the drawings, the same components will be given with the same reference numerals, omitting the repeated explanation.

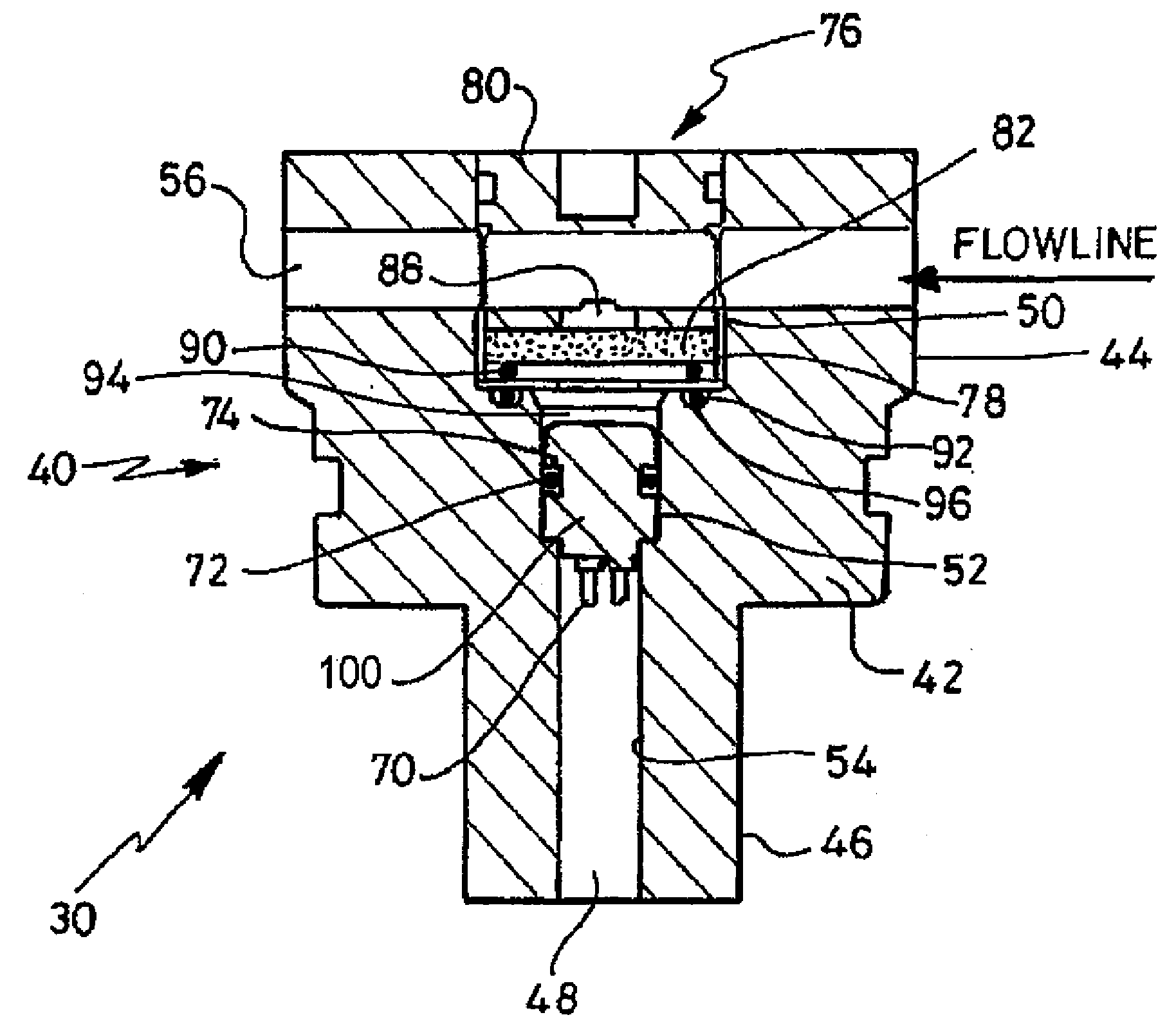

[0029]FIG. 1 shows the structure of a wellbore tool 10. The wellbore tool 10 is based on Schlumberger's Modular Dynamics Tester (MDT) (Schlumberger trademark), as described in U.K. patent publication number 2397651A. The wellbore tool 10 of the present embodiment is used for sensing or measuring contents of a specified component in hydrocarbons in a high pressure condition and / or a high temperature condition.

[0030]The tool 10 includes an elongate substantially cylindrical body 12, which in operation is su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com