Fluid pump

a technology of fluid pump and pump body, which is applied in the direction of non-positive displacement fluid engine liquid fuel engine components, etc., can solve the problems of large and therefore most expensive parts in production, and the need for small mounting space, so as to reduce costs and improve efficiency , the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

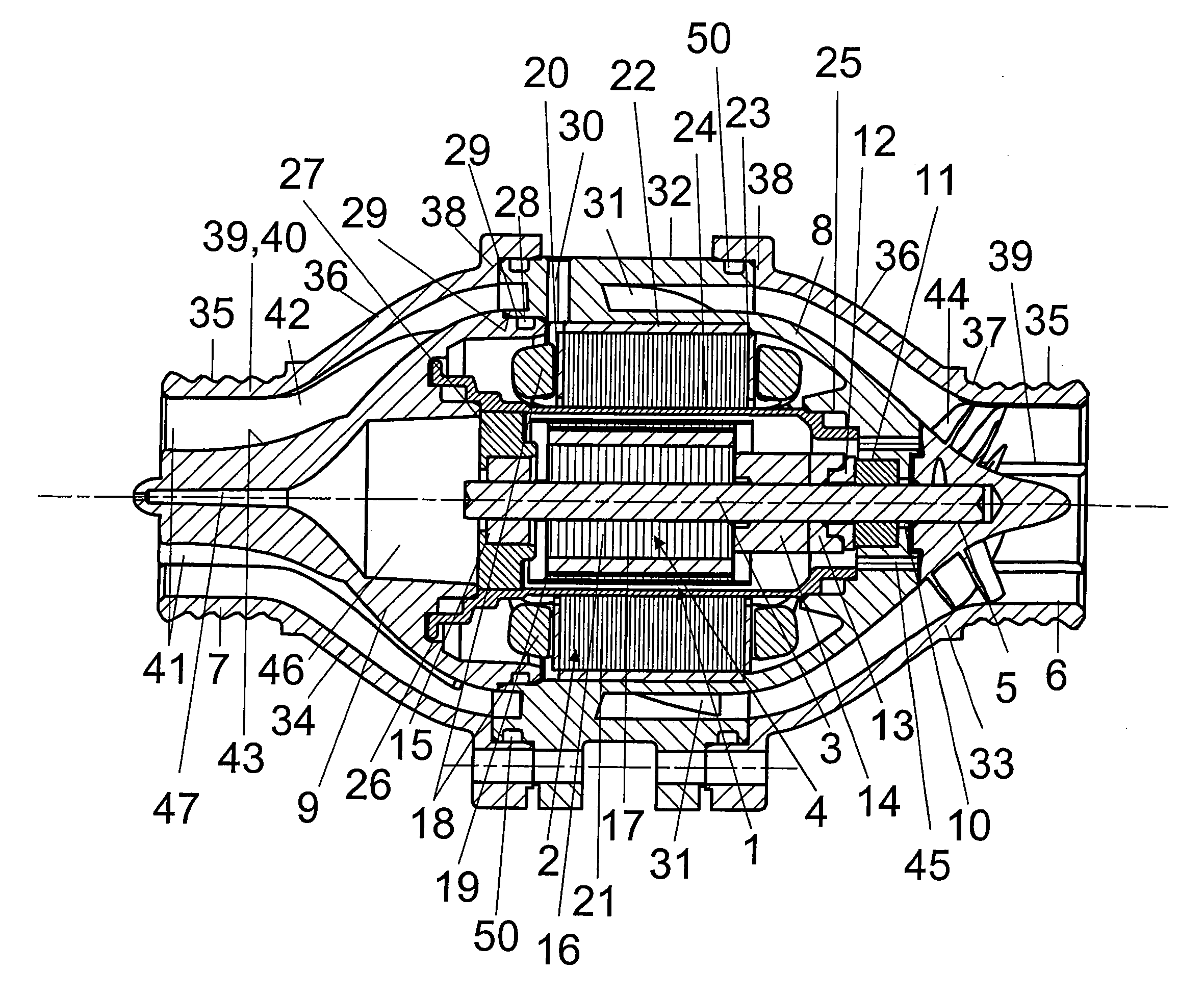

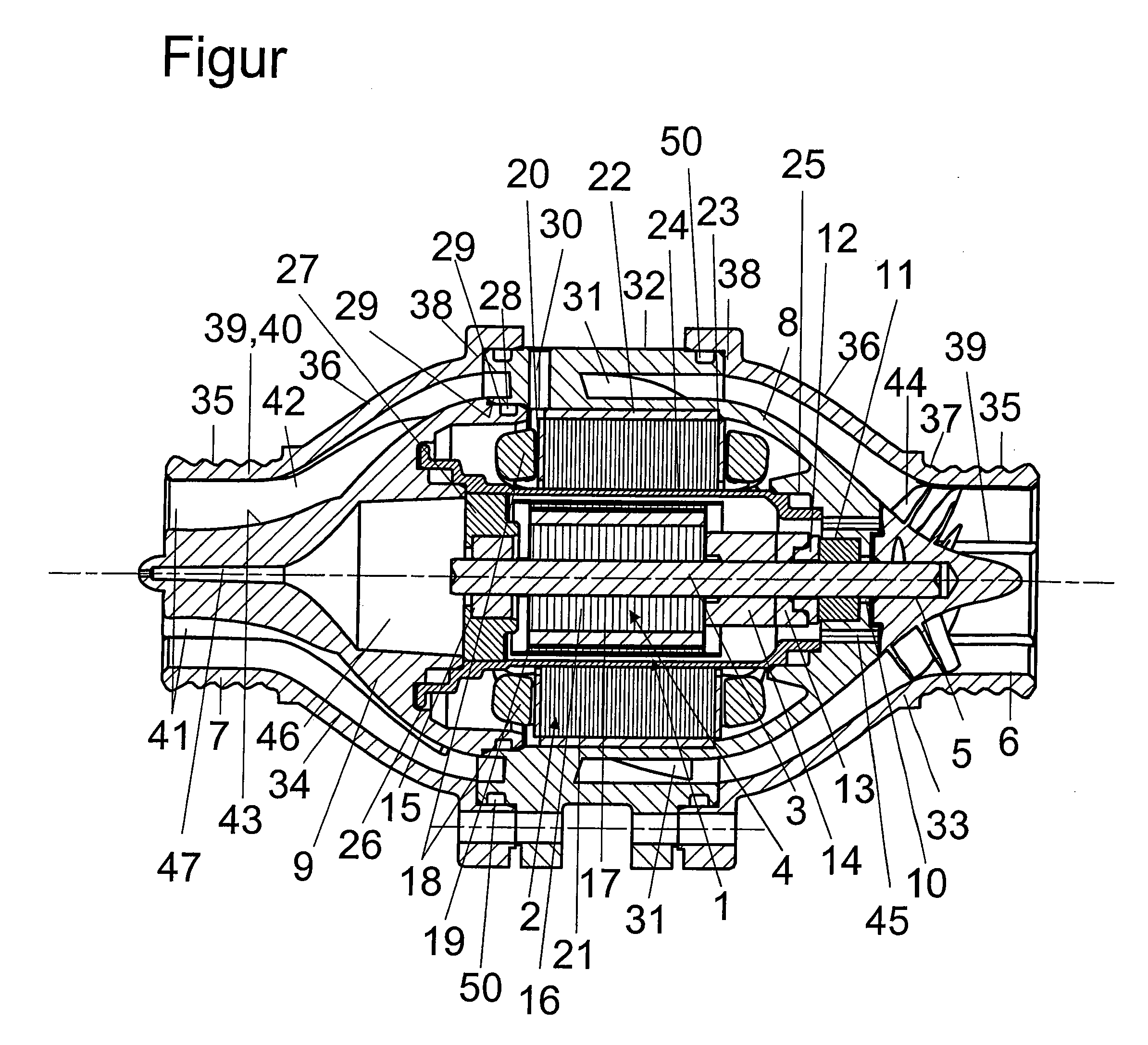

[0016]The fluid pump illustrated in the FIGURE, which is particularly suited as a coolant pump in internal combustion engines, is driven by an electronically commuted electric motor 1, formed by a stator 2 and a rotor 4 arranged on a drive shaft 3. The axial end of the drive shaft 3 is provided with an impeller 5 that is realized in a semi-axial construction and by whose rotation the fluid to be conveyed, especially a coolant, is conveyed substantially axially from an intake port 6 through the fluid pump to a pressure port 7.

[0017]The electric motor 1 is arranged in a motor housing formed by a first, suction-side motor housing part 8 and a second, pressure-side motor housing part 9. The drive shaft 3, on which the impeller 5 is arranged, is passed through the suction-side motor housing part 8. For this purpose, the suction-side motor housing part 8 has a bore 10 with a first bearing 11 being arranged therein for supporting the drive shaft 3. Behind the first bearing 11, seen from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com