Metal Wood Club with Improved Moment of Inertia

a golf club and metal wood technology, applied in the field of improved metal wood golf club head, can solve the problems of limiting the mass characteristics of the club head, the shape of the driver club is substantially different, and the environmental effects are beyond the control of the golf equipment designer, so as to achieve the effect of greater density or thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

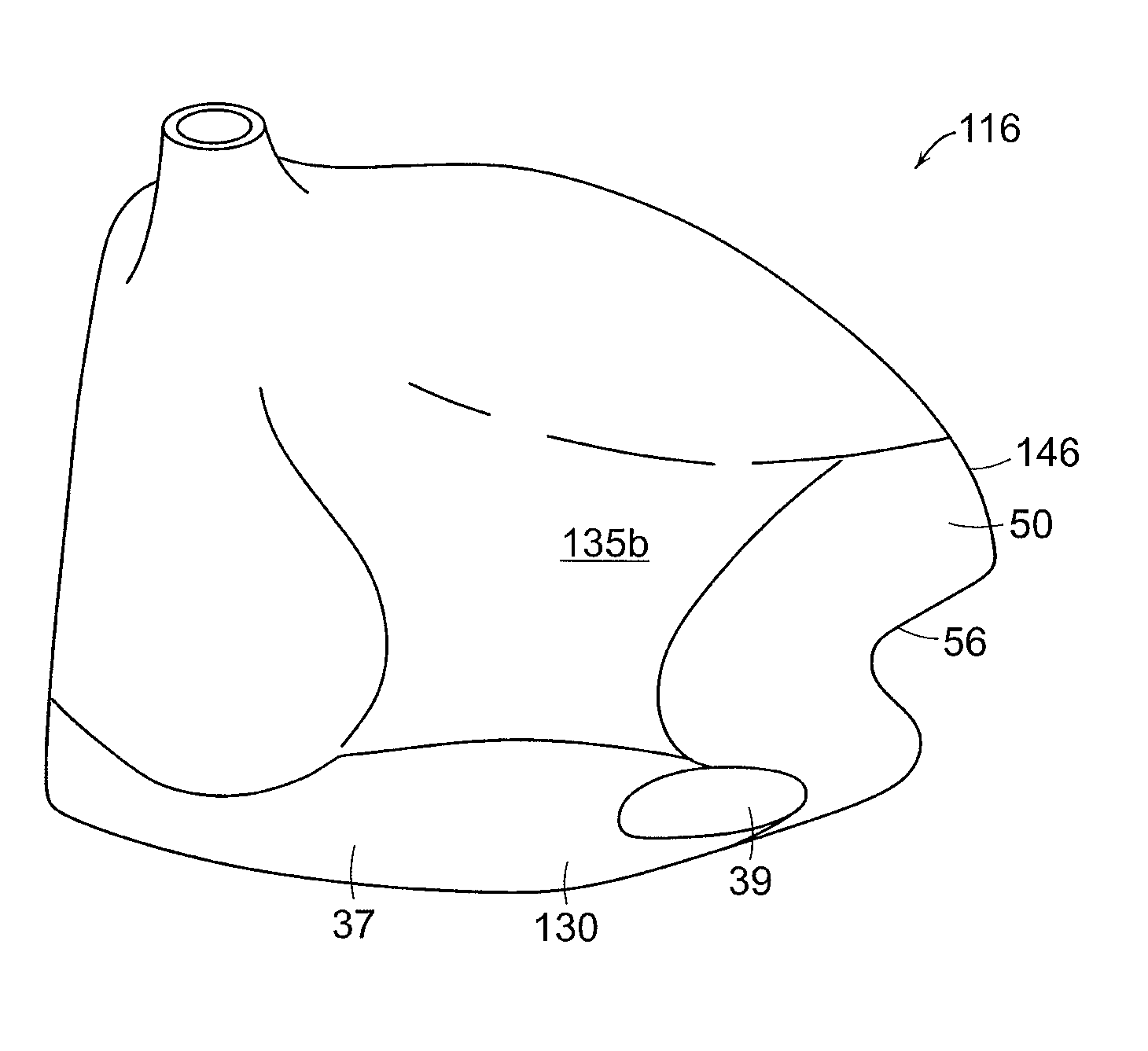

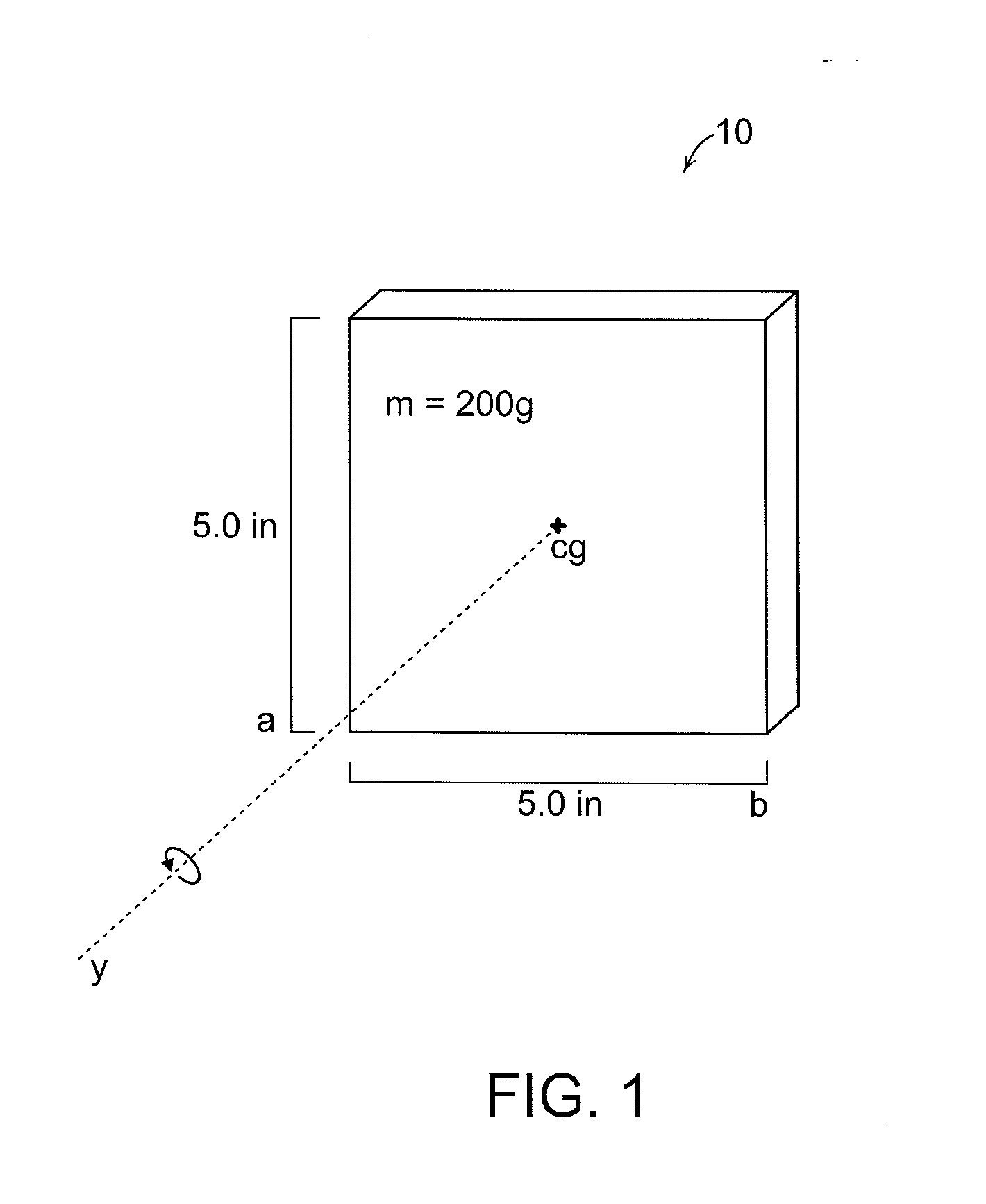

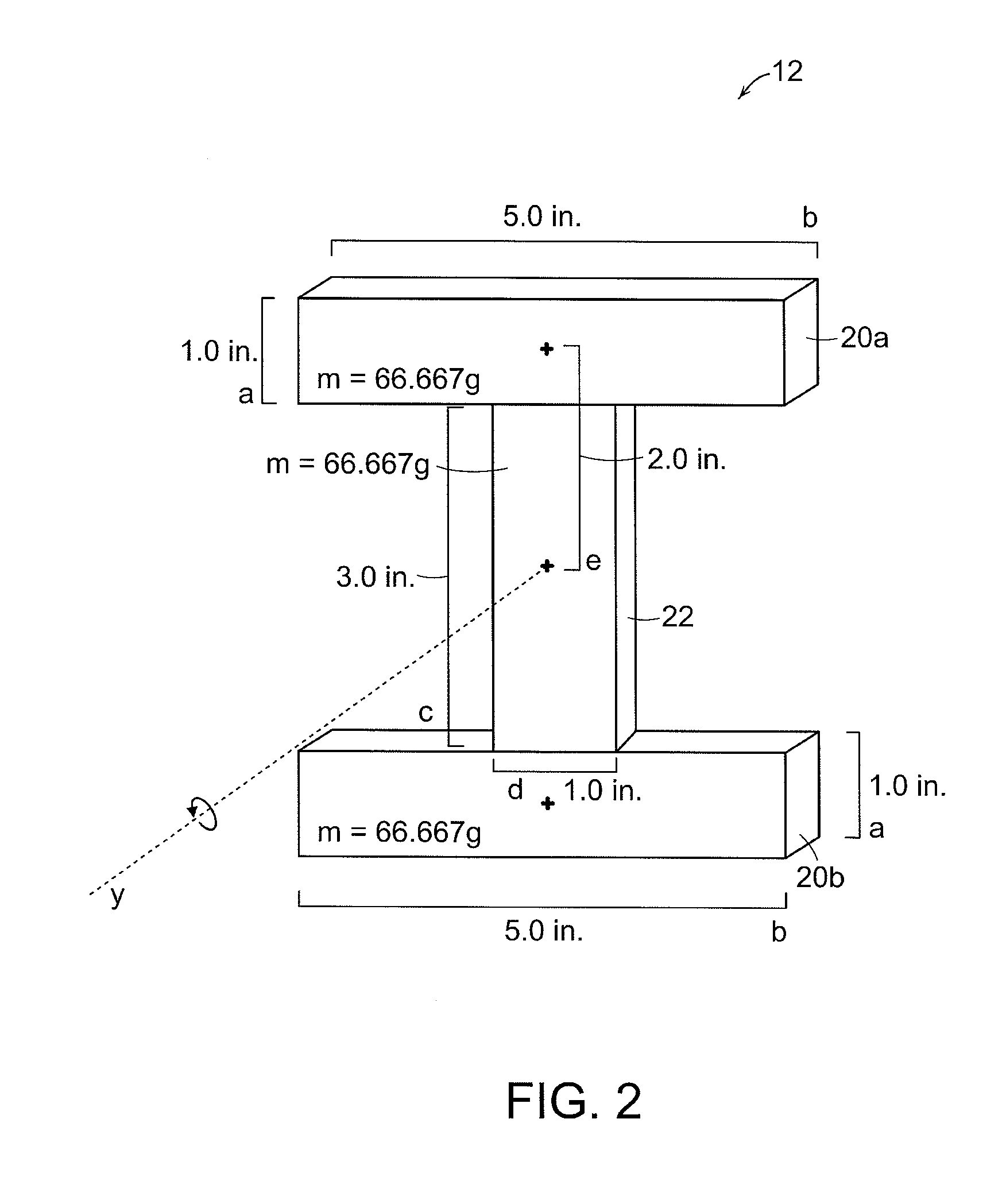

[0024]Rotational moment of inertia (“MOI” or “inertia”) in golf clubs is well known in the art, and is fully discussed in many references, including U.S. Pat. No. 4,420,156, which is incorporated herein by reference in its entirety. When the inertia is too low, the club head tends to rotate excessively from off-center hits. A golf club head having a higher moment of inertia will resist rotation due to an off-center impact between the club face and a golf ball, thereby mitigating the tendency for the ball to hook or slice and increasing flight distance and landing accuracy. The present invention is directed to a hollow body golf club head having discrete concentrations of weight or mass located away from the center of gravity or the geometric center of the club head to optimize the moment of inertia of the club head about the vertical axis running through the center of gravity, hereinafter called the y-axis. In particular, the present invention is directed to a hollow body driver, hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com