Munition or projectile for battlefield illumination

a projectile and battlefield technology, applied in the direction of projectiles, ammunition projectiles, weapons, etc., can solve the problems of increased fire danger, increased danger to persons and the environment, and regular risk of pyrotechnic materials, so as to avoid undesired blinding and sufficient illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

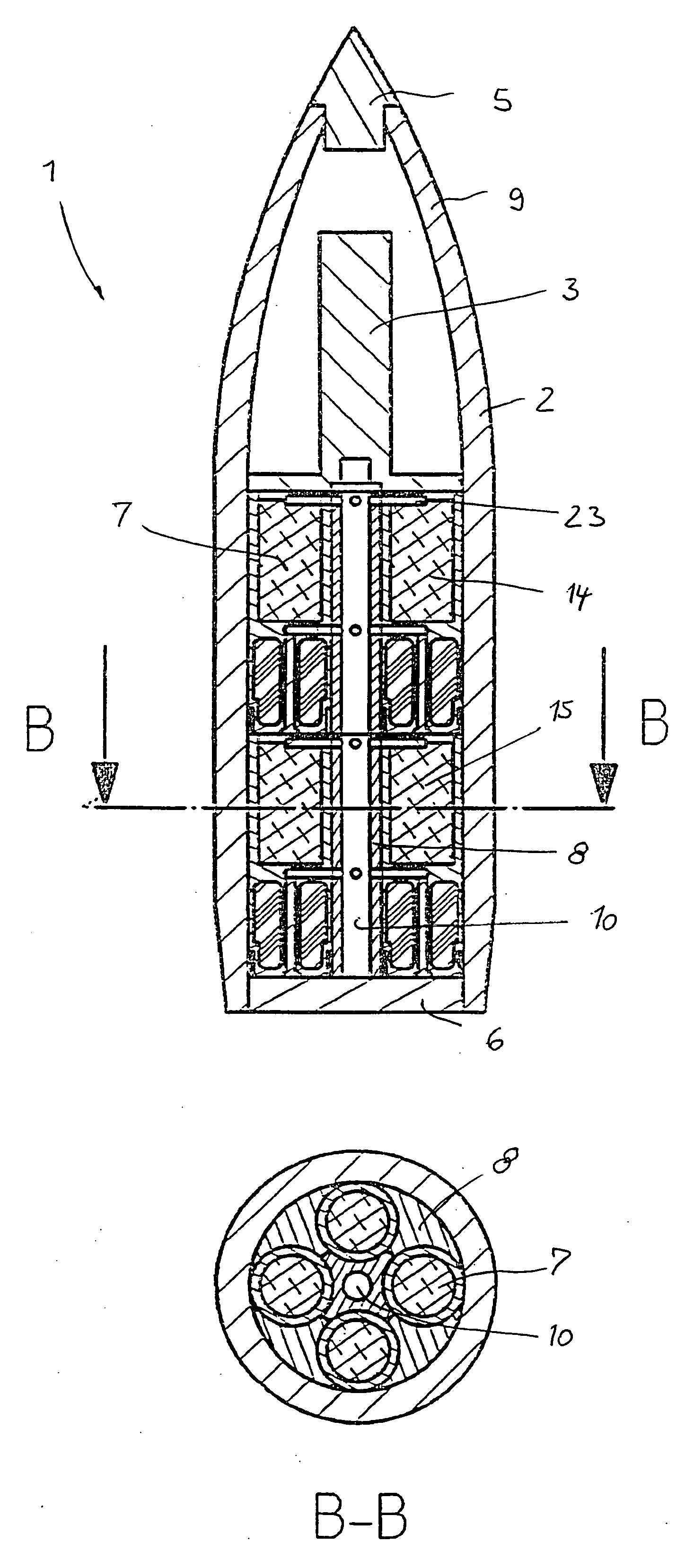

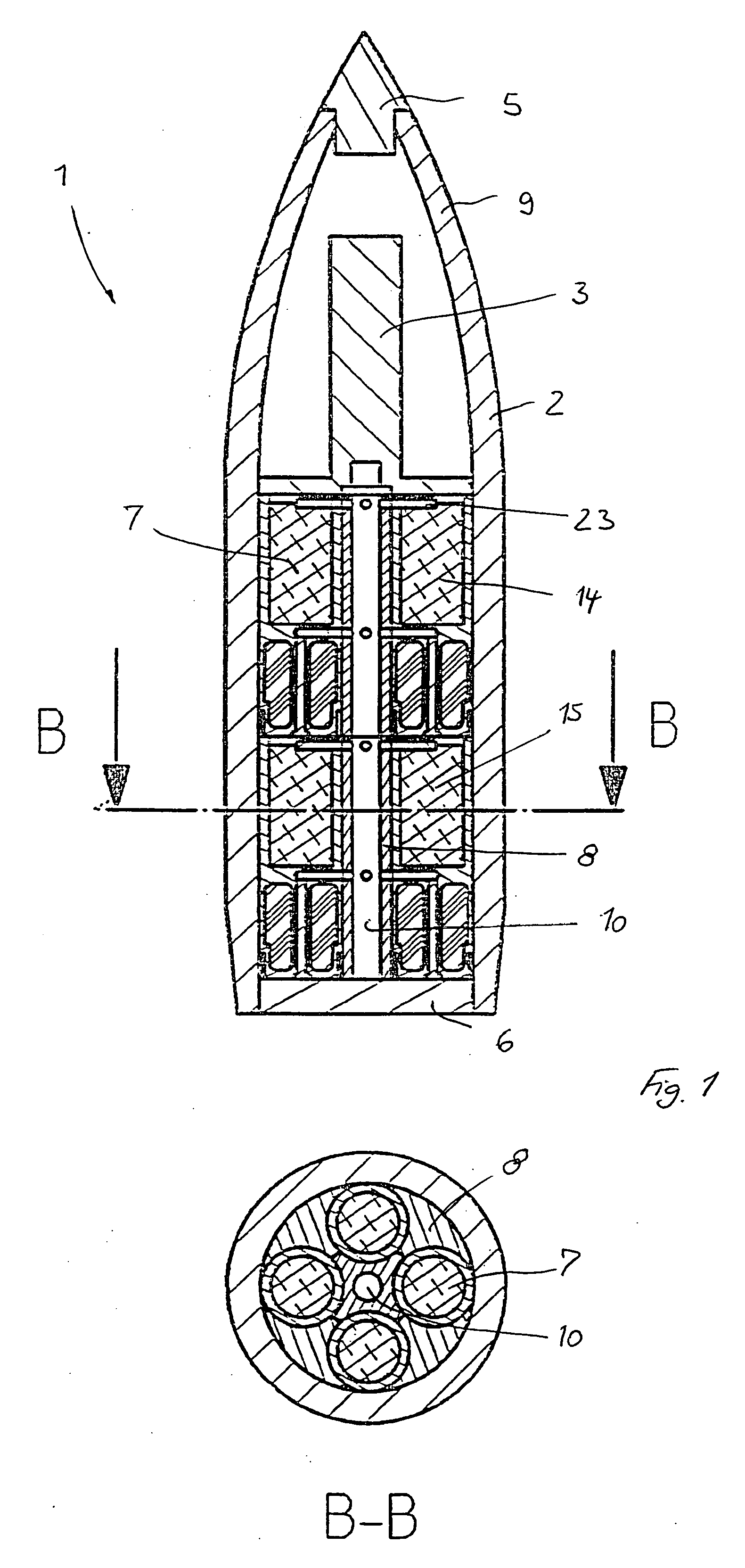

[0023]FIG. 1 shows a projectile 1, which consists of a projectile body 2, an expulsion charge 3 and an expulsion plate. Besides a projectile fuse 5 and a projectile base 6, the projectile 1 contains flare bodies 7 and filler elements 8. In the present case, the flare bodies 7 are positioned on two levels 14, 15. In the case illustrated here, eight flare bodies 7 are incorporated in the projectile 1. The filler elements 8 preferably form a central channel 10 in the projectile 1 for the expulsion gases, by which the delay elements 11, 12 of the flare bodies 7 are ignited.

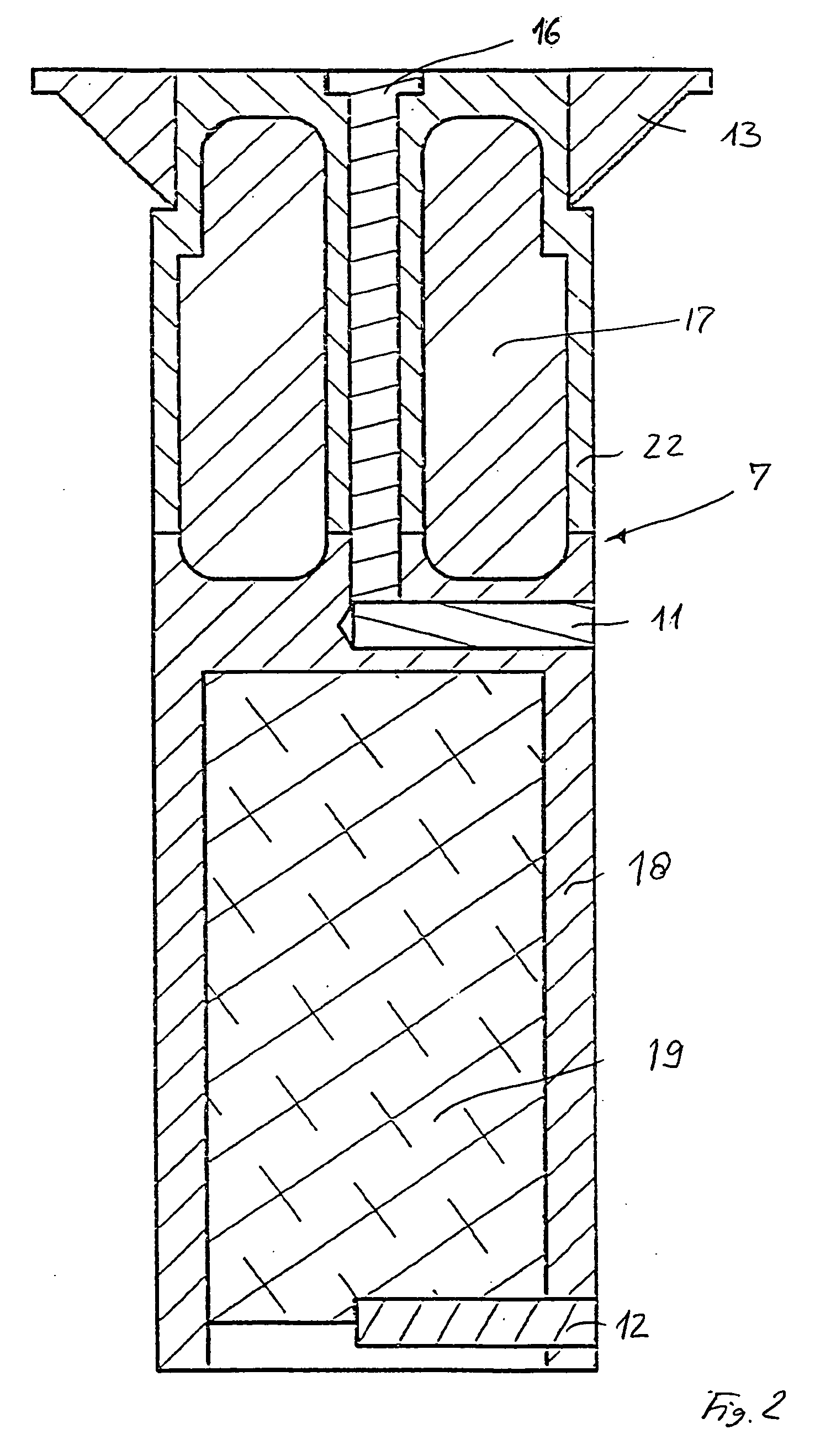

[0024]The individual flare body 7 itself consists of a jacket 18, which houses, for example, a pyrotechnic compound 19, then, at least in this case, preferably two delay elements 11, 12 or a twin-stage delay element, an expulsion system 16, 22, and a parachute 17 (FIG. 2). A stabilizing element 13 is located on the outer jacket, but this is not absolutely necessary.

[0025]The time after which the expulsion charge 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com