Iron-based alloy and process for producing the same

a technology of iron-based alloys and fe-based alloys, which is applied in the direction of magnetic materials, magnetic bodies, electrical equipment, etc., can solve the problems of inferior ductility of ni—mn—ga-based materials, temperature control of shape-memory alloys, and poor response, so as to achieve a large reversible strain, high elastic deformation, and displacably controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0040]Fe-based alloys having compositions of Table 1 were melted, cast, hot-rolled and cold-rolled to a plate thickness: 0.5 mm. Further, the Fe-based alloys were solution-treated at 1000° C. for 60 minutes. For alloy designs in Table 1, alloys A1 to A5 are based on an Fe—Al-based alloy; alloys S1 to S4 based on an Fe—Si-based alloy; alloys C1 to C4 based on an Fe—Cr-based alloy; and alloys N1 to N4 based on an Fe—Ni-based alloy. Alloys A5, A6, S5, S6, C5, C6, N5 and N6 are obtained by combining a plurality of fundamental Fe-based alloys.

TABLE 1Prepared Fe-based alloyalloy component, contentalloy(% by mass)No.AlSiCrNiFeA12———balanceA25———balanceA37———balanceA410 ———balanceA553——balanceA65—12—balanceS1—0.5——balanceS2—1.5——balanceS3—3——balanceS4—6——balanceS5—312—balanceS6—3—45balanceC1—— 5—balanceC2——12—balanceC3——18—balanceC4——22—balanceC5——1245balanceC62—12—balanceN1———36balanceN2———40balanceN3———45balanceN4———50balanceN52——45balanceN6—0.51245balance

[0041]Table 2 shows results obtai...

example 2

[0046]Alloys A2, S3, C2 and N3 of Table 1, which were selected as a Fe—Al-based, Fe—Si-based, Fe—Cr-based and Fe—Ni-based alloys, were cold-worked and aging-treated after being solution-treated.

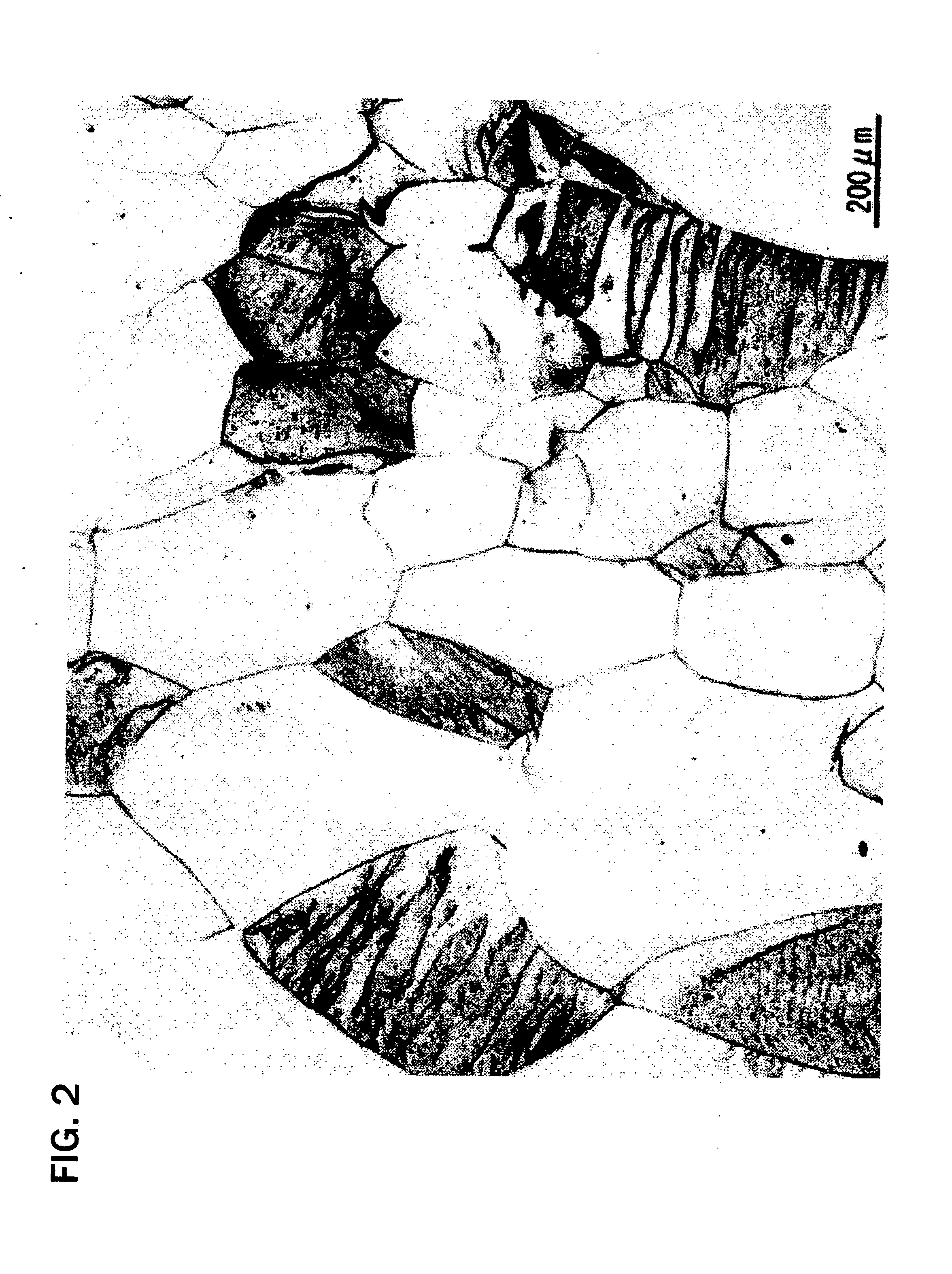

[0047]The relationship between producing conditions and property values is shown in Table 3. In test No. 1, cold rolling was not carried out after being solution-treated, and twin crystals did not exist. Test No. 2 is obtained by applying cold-rolling of 40% to the test No. 1, and the elastic deformation amount was also large. Test No. 3 was rolled at a cold working rate of 80%, and the area ratio of the twin crystal interface and the elastic deformation amount increased with the increase in the working rate. However, the magnetization intensity had no change and magnetic property was well maintained.

[0048]Test Nos. 7 to 12 are aging-treated after being solution-treated and cold-rolled. In the test Nos. 7-8 and 10-11, the area ratio of the twin crystal interface is 0.2 or more, and the suitab...

example 3

[0051]Alloys A3, S2, C3 and N3 of Table 1 respectively have a Fe—Al-based, Fe—Si-based, Fe—Cr-based and Fe—Ni-based fundamental compositions. Various Fe-based alloys were prepared by adding a third component of claim 2 or 4. The Fe-based alloys were cast, hot-rolled and cold-rolled to a plate thickness: 0.5 mm in the same manner as in Example 1 after being melted. The Fe-based alloys were cold-rolled and aging-treated after being solution-treated.

[0052]Table 4 (Fe—Al-based), Table 5 (Fe—Si-based), Table 6 (Fe—Cr-based) and Table 7 (Fe—Ni-based) show results obtained by measuring the elastic deformation amount and magnetization intensity of each of the obtained Fe-based alloys.

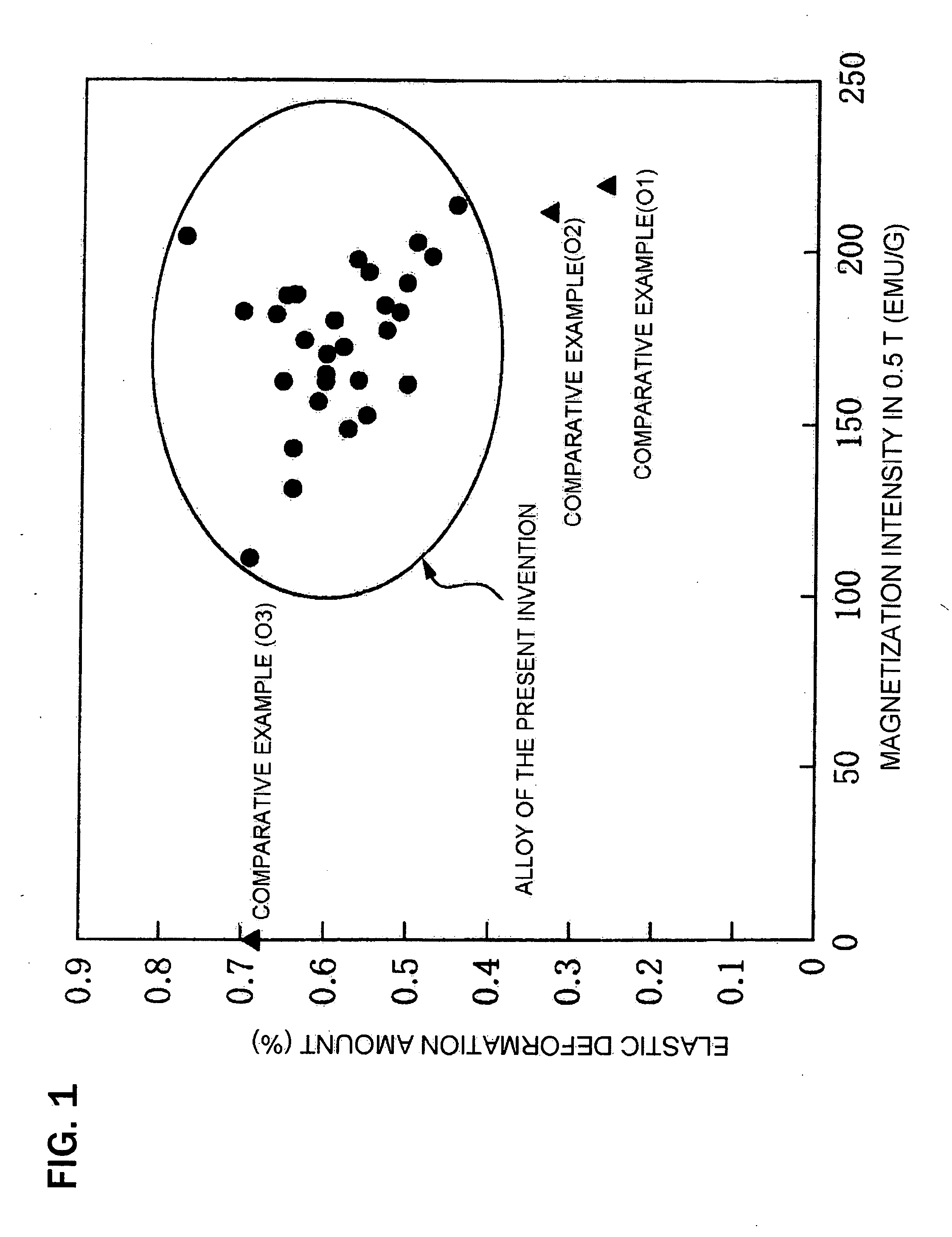

[0053]As shown in search results of Tables 4 to 7, each of Fe-based alloys having enhanced magnetism, a corrosion resistance, strength and ductility or the like obtained adding a third element exhibited an area ratio of a twin crystal interface of 0.6 or more. The Fe-based alloy had an elastic deformation amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| external magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com