Electrically powered pump

a technology of electric motors and winding wires, which is applied in the direction of pumping, positive displacement liquid engines, machines/engines, etc., can solve the problems of winding wire corrosion, corrosion of winding wires, and corrosion of copper conductive bodies,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

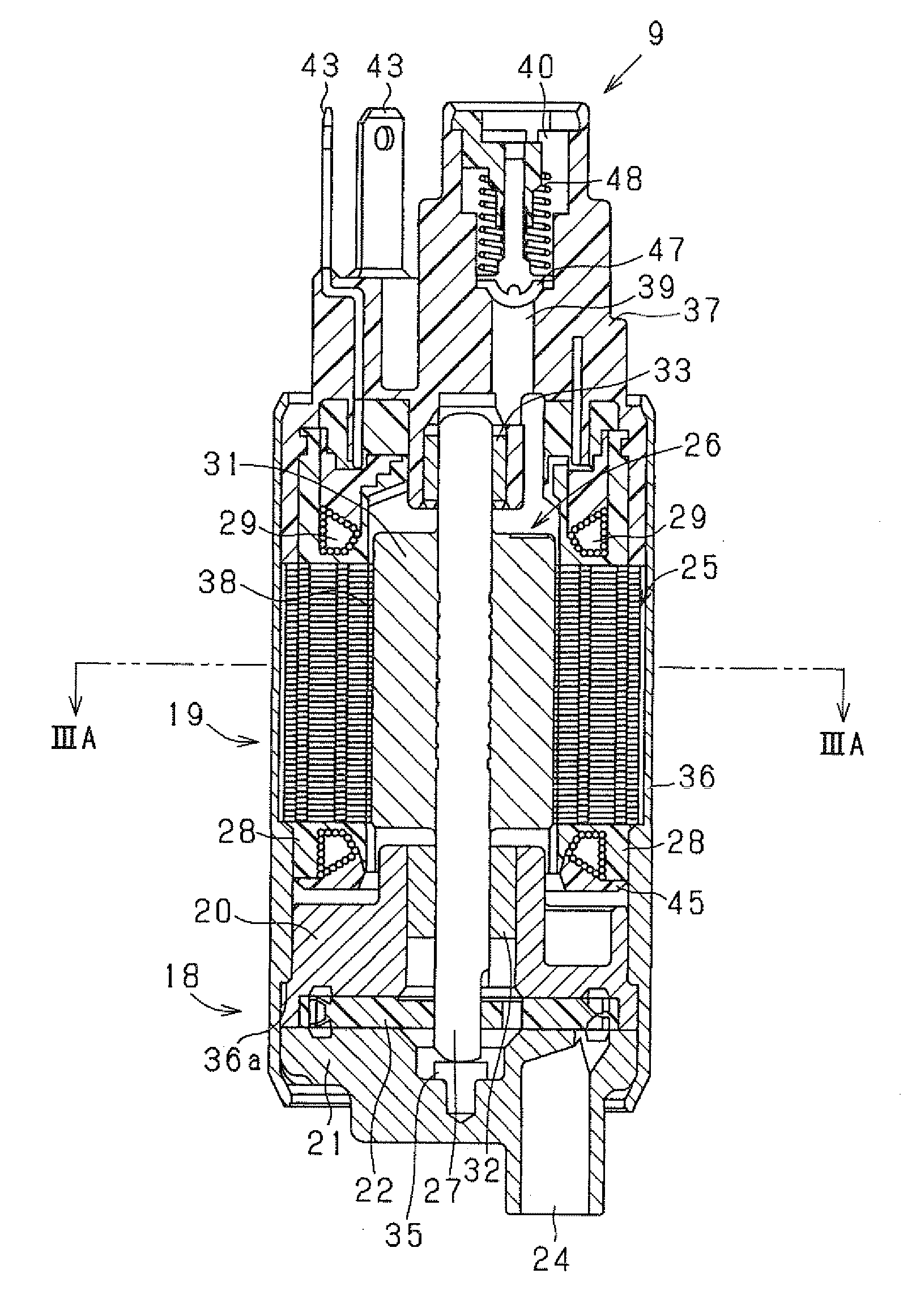

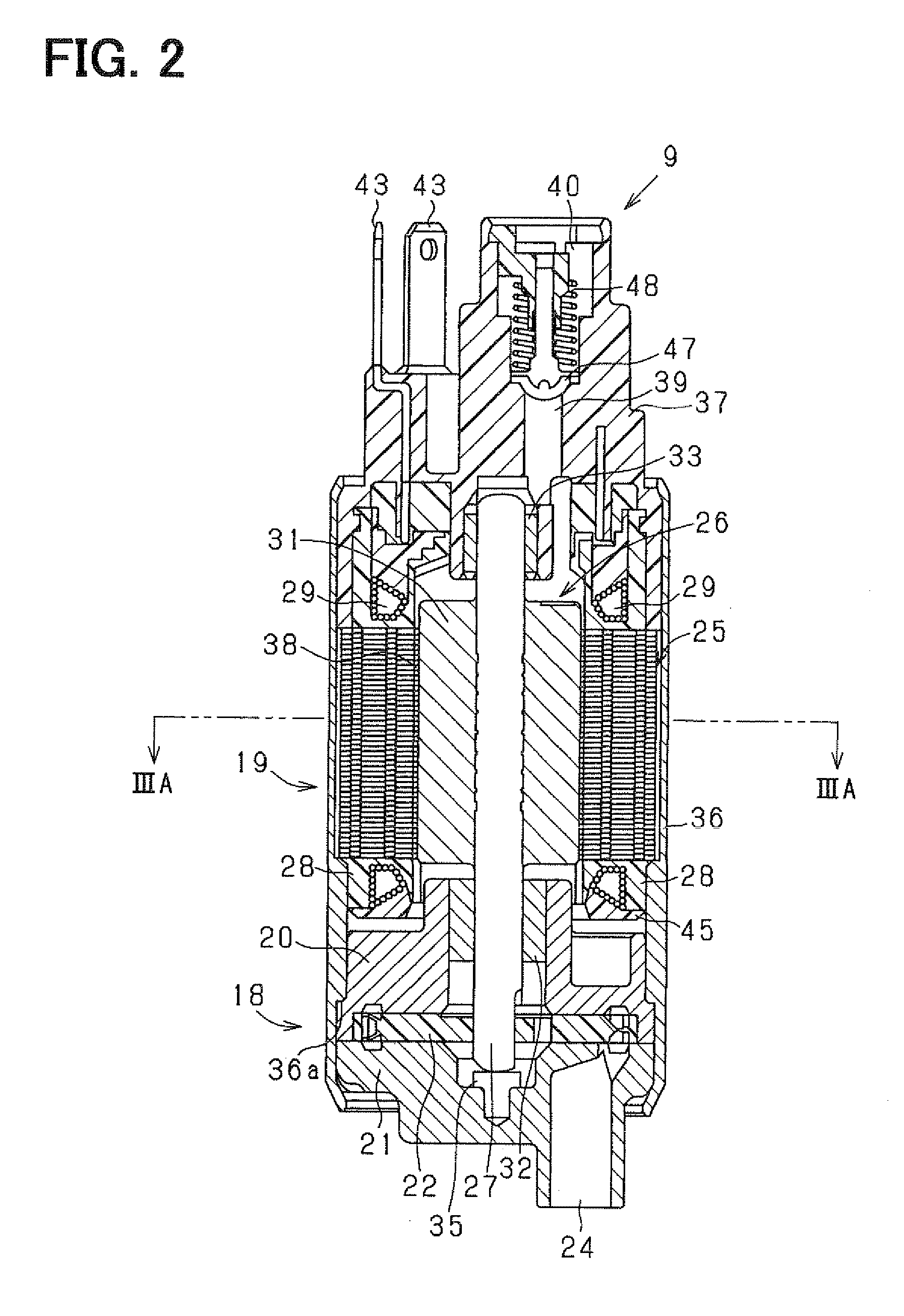

[0022]An electrically powered pump according to one embodiment of the present invention will be described hereafter, with reference to the accompanying drawings.

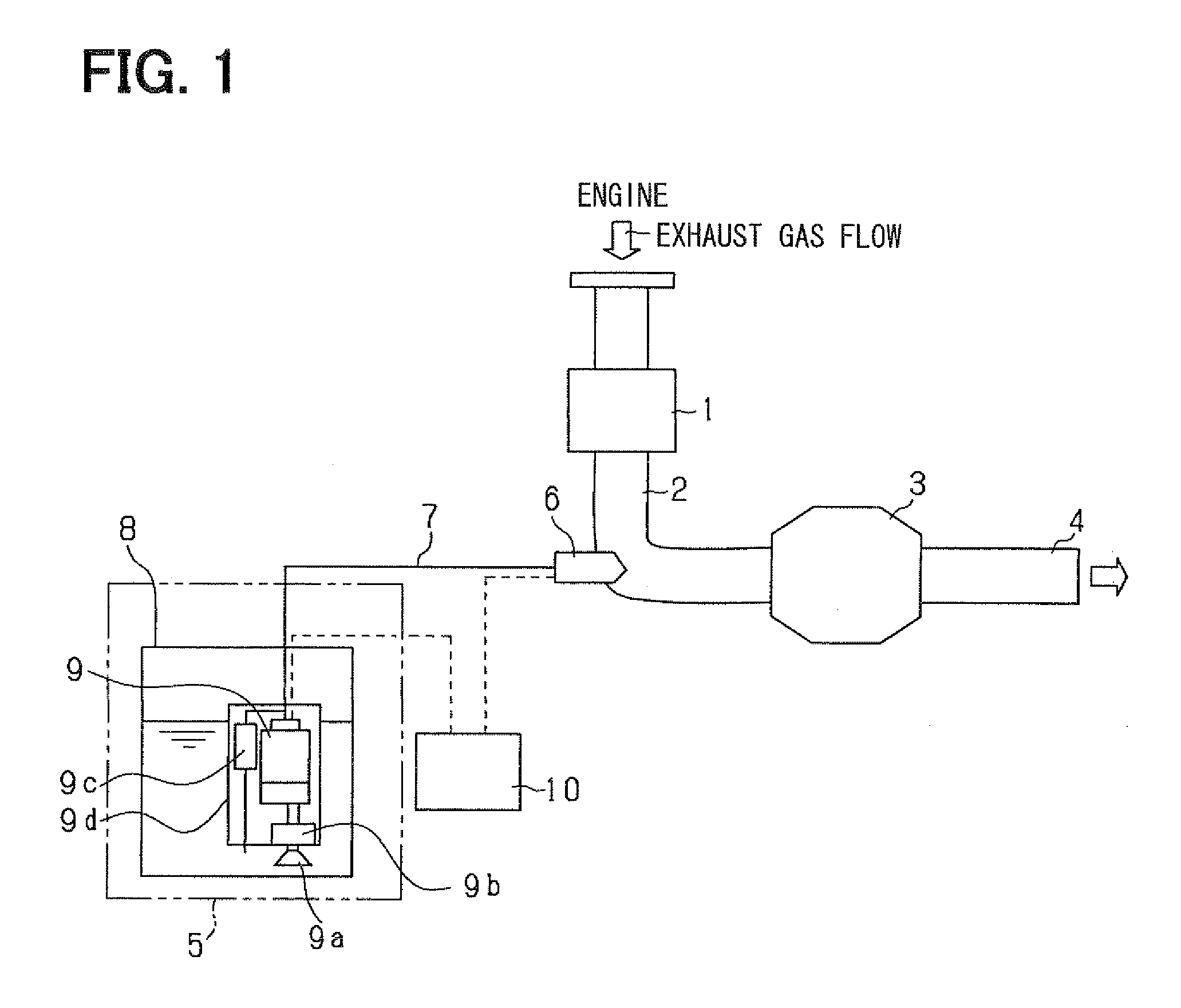

[0023]The electrically powered pump according to the present embodiment is applied to a urea water pump that pumps urea water solution (hereafter referred to just as urea water) that contains urea as a reducing agent. The urea water discharged from the urea water pump is pressurized and pumped to an addition valve. The addition valve is so installed as to inject the urea water in an exhaust gas flow in an exhaust passage of a diesel engine (hereafter referred to as engine), which is an internal combustion engine.

[0024]FIG. 1 schematically shows an entire construction of a urea SCR system in which the urea water pump (electrically powered pump) according to the present embodiment is incorporated. FIG. 1 depicts an exhaust emission control device in which exhaust gas discharged from the engine of a vehicle (not shown) is clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com