Bio-degradable cup and method for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

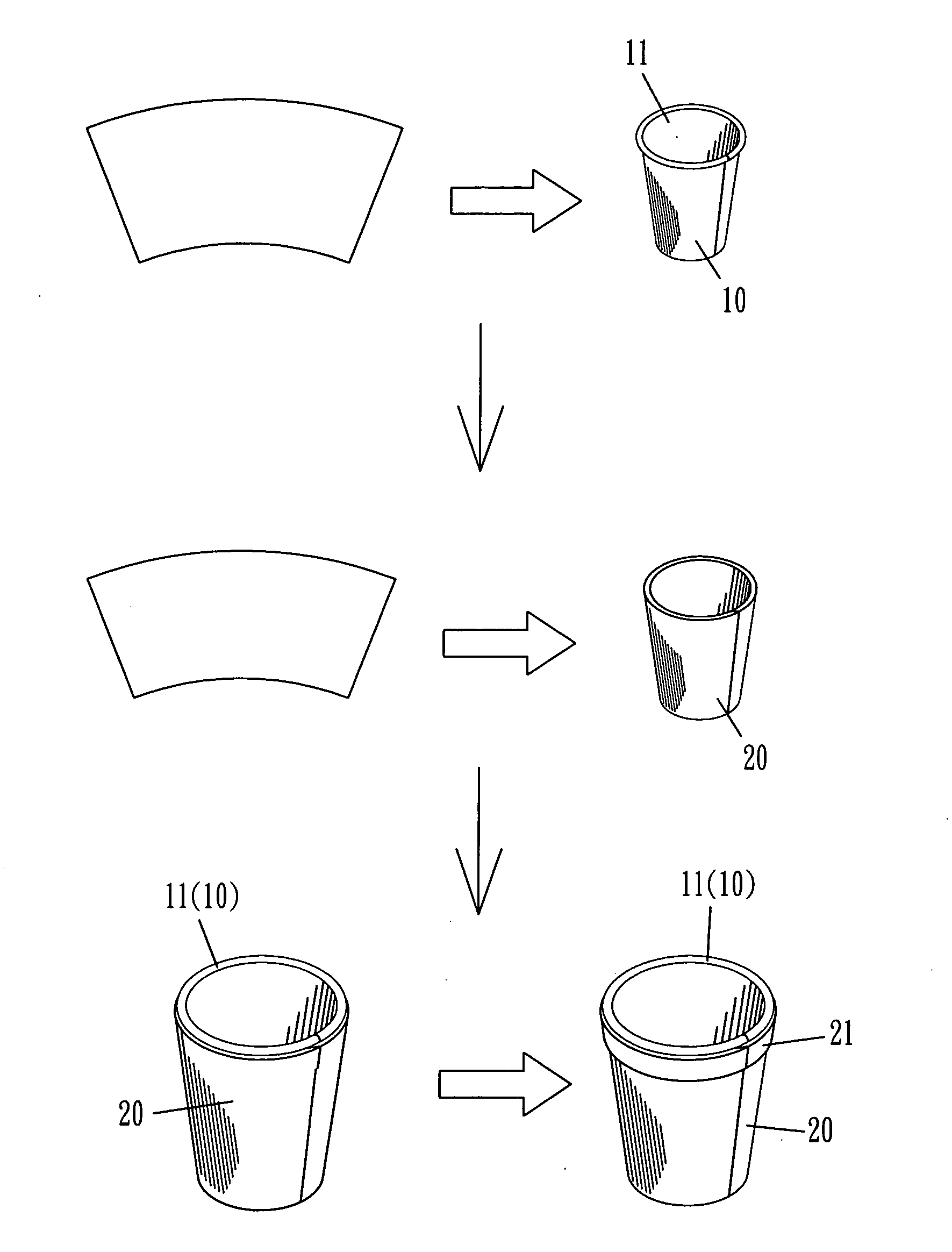

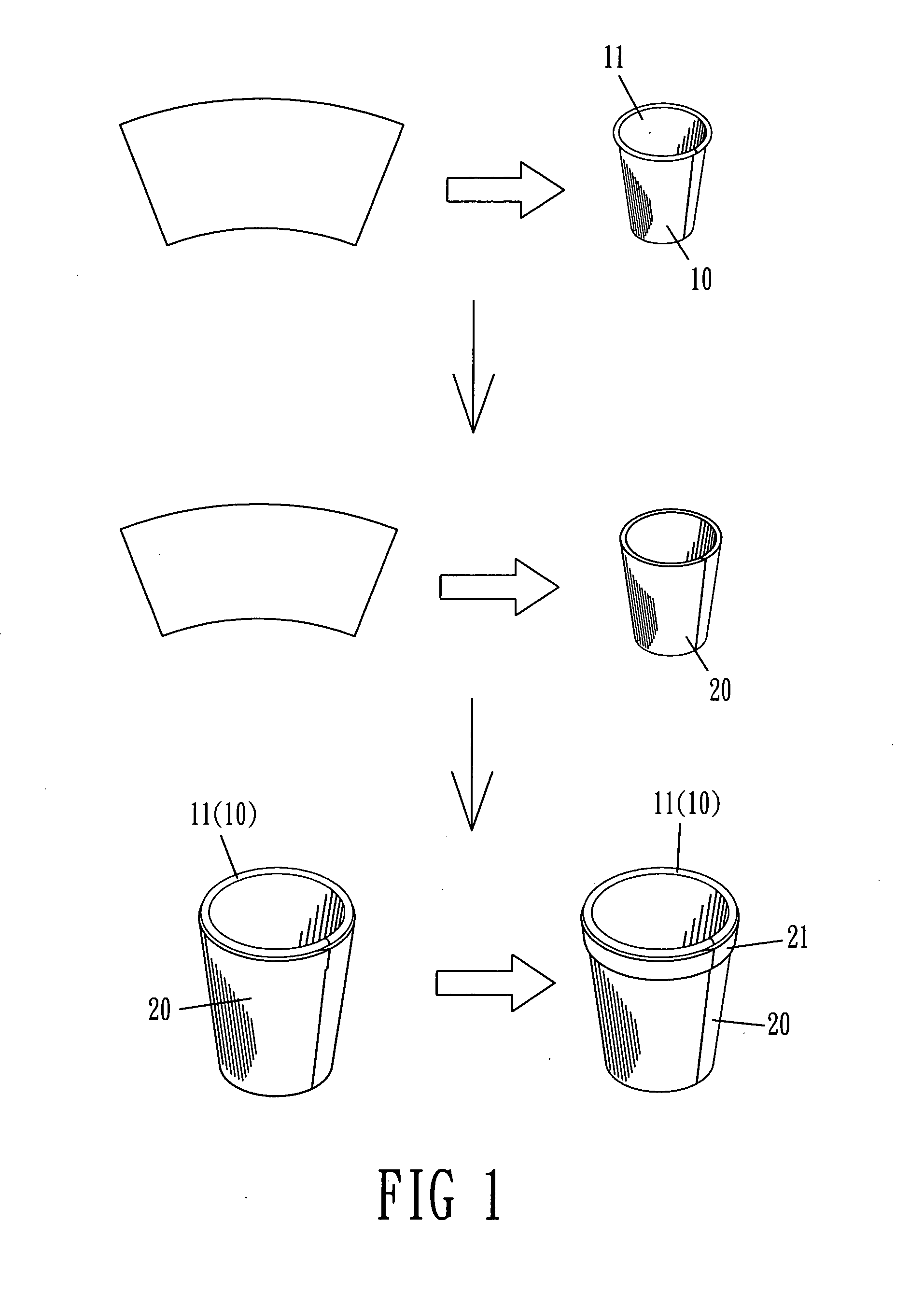

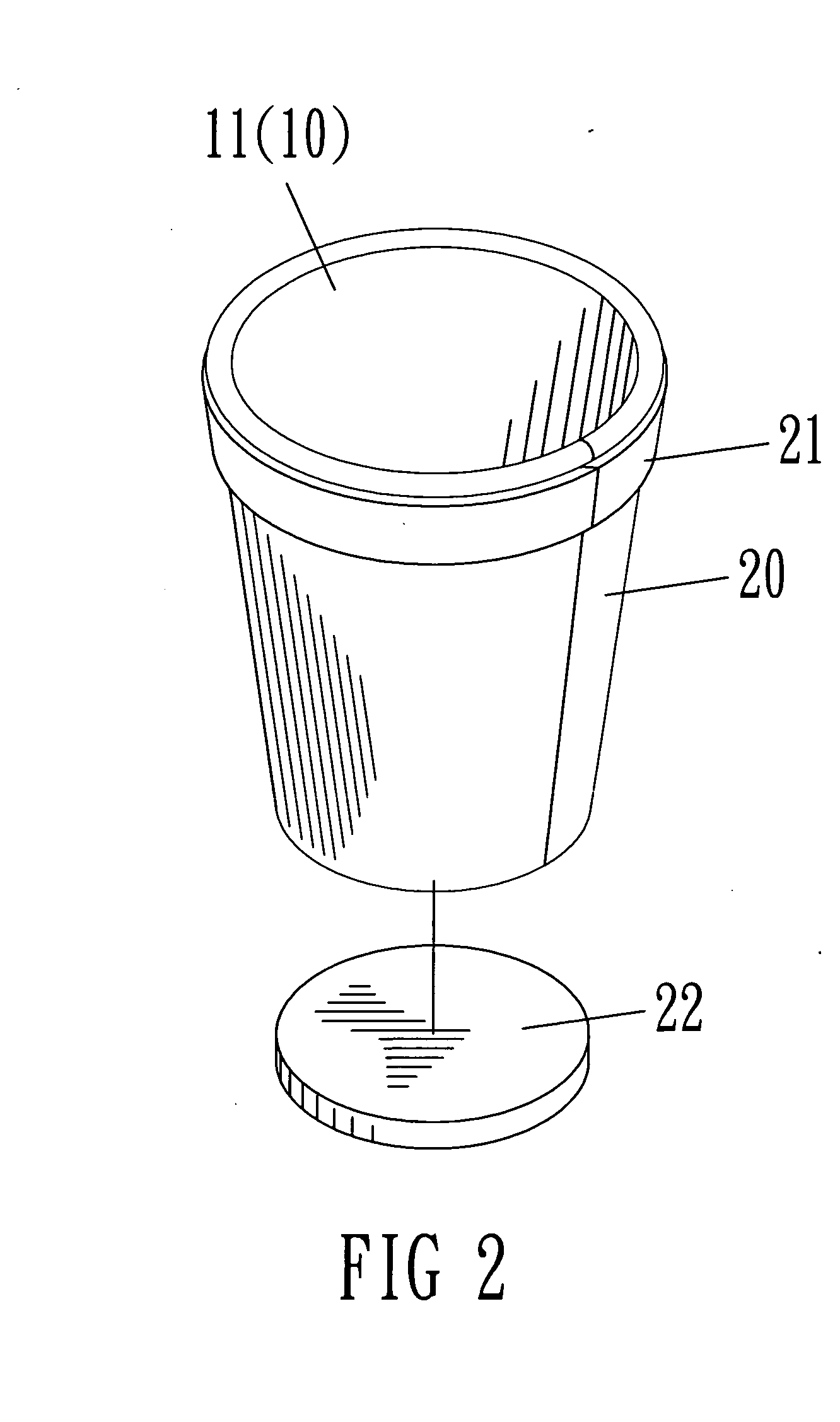

[0020]Referring to FIG. 1, the method for making the bio-degradable cup of the present invention comprises a step of preparing a paperboard with bio-degradable film 11 coated on at least inner or outer surface thereof, the paperboard then being cut, folded and heat-pressed to be a paper cup 10. The bio-degradable film 11 is made by Plolylactic Acid (PLA), Bio-Polymers, bio-degradable plastic or any plastic material meets requirements ISO14855 and suitable to be composted.

[0021]A step of preparing a foam board 200 made by bio-degradable plastic or non-bio-degradable plastic which is treated by way of super-critical carbon dioxide extrusion. The foam board 200 is a microfoam and is applied with a printing process which can be water relief printing, intaglio printing, lithography, screen printing or rotary screen. Desired patterns or characters can be printed to the outside of the foam board 200 and the foam board 200 is cut into pieces and each piece is made to be a foam cup 20 via ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Biodegradability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap