Abuse resistant preform and container neck finish

a preform and container neck technology, applied in the field of plastic preforms and containers, can solve the problems of affecting the quality of the product, and affecting and achieve the effect of increasing the service life of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]In accordance with various embodiments of the invention, a neck finish of a preform or container is provided having a crystallized top sealing surface for withstanding the abuse of multiple use cycles.

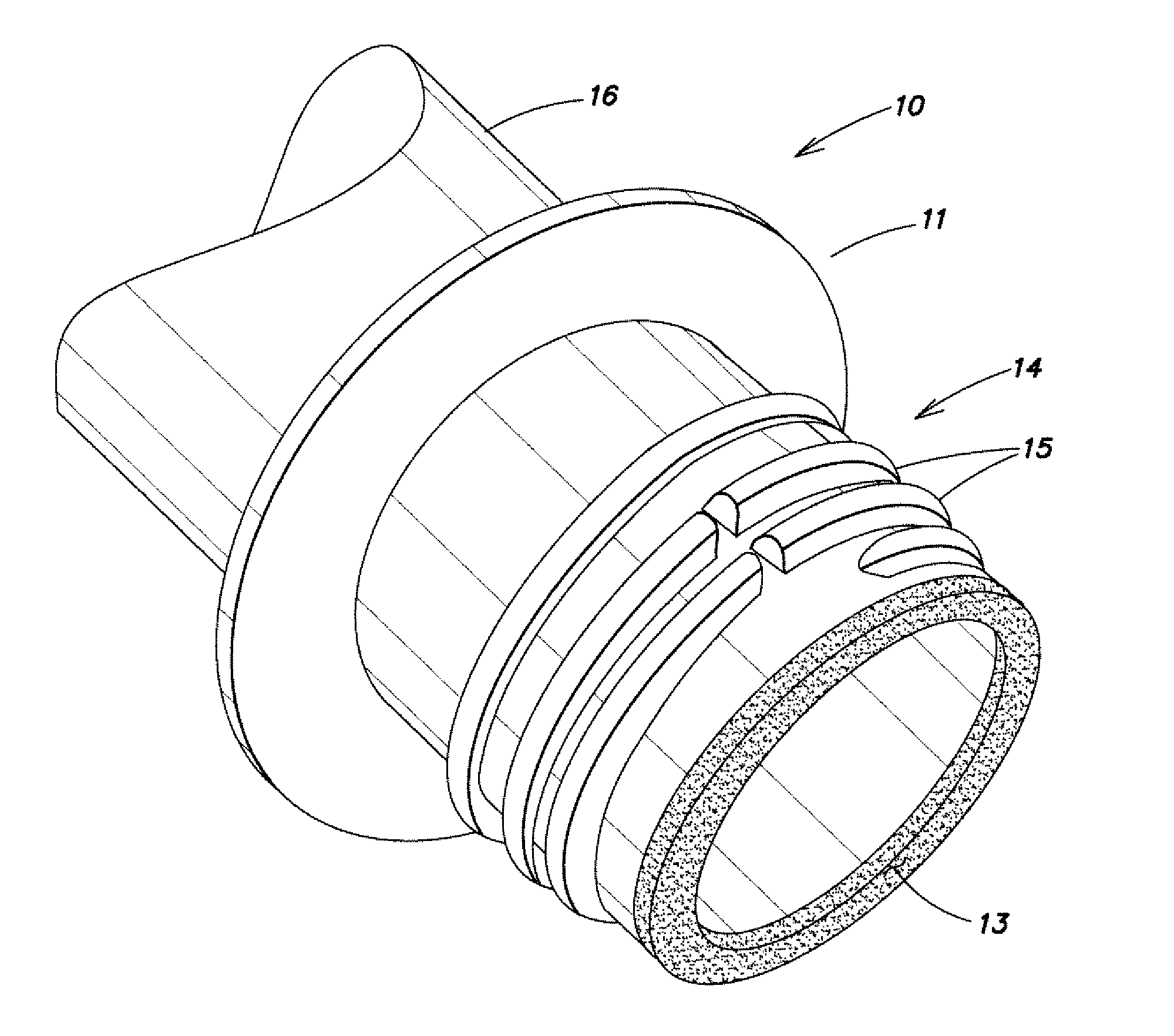

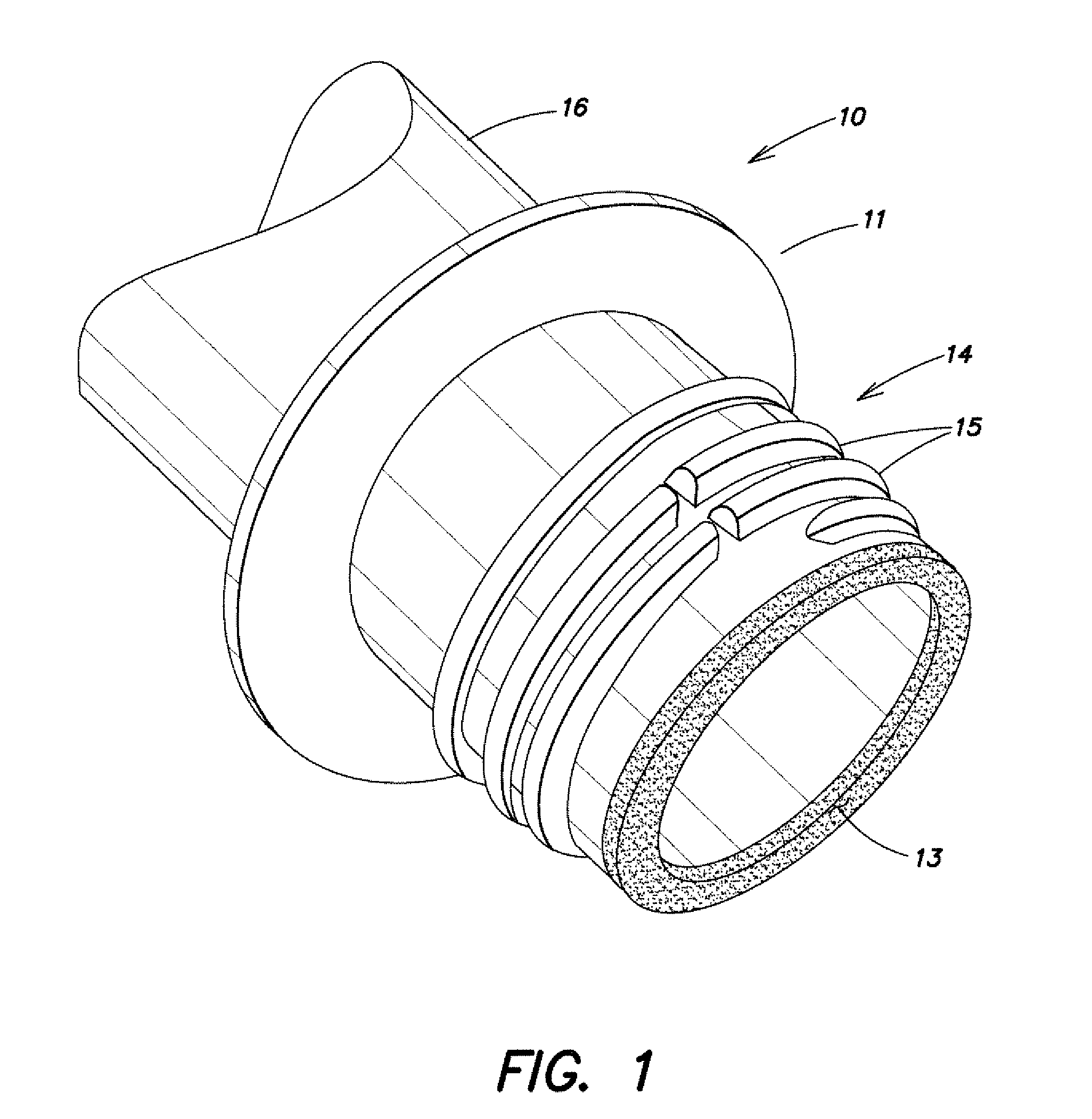

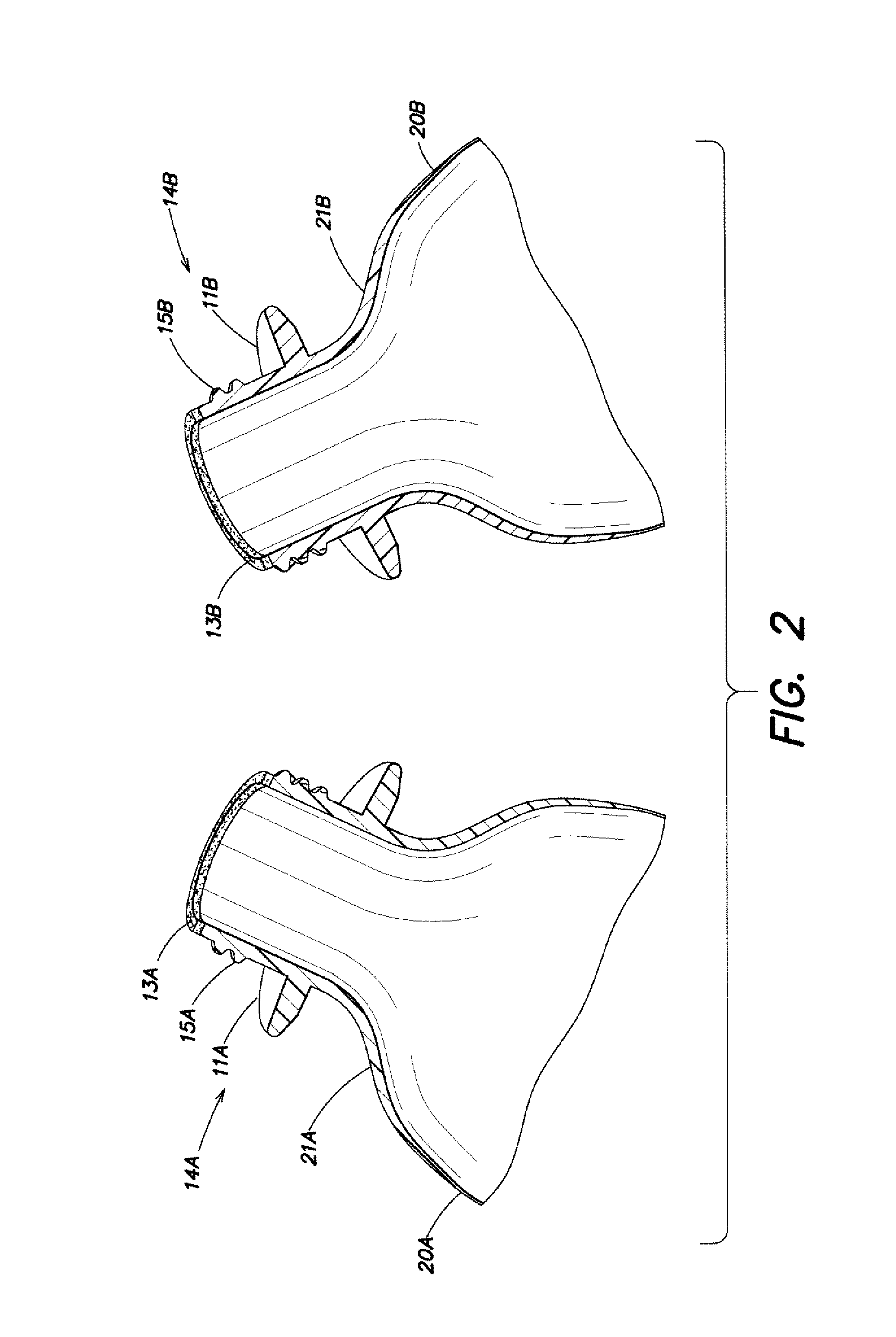

[0023]One exemplary embodiment of a preform and container having a neck finish with a crystallized top sealing surface (TSS) according to the invention is illustrated in FIGS. 1-6. FIGS. 1-2 show a sample preform having a crystallized TSS, and the resulting container finish having a crystallized TSS. FIGS. 3-4 show two examples of closures applied to the finish, illustrating the seal between the crystallized TSS and interior top surface of the closure. FIGS. 5-6 show cross sections of a preform and the resulting blow molded refillable container.

[0024]FIG. 1 shows the top end of a preform 10 including a tapered shoulder portion 16, an increased diameter capping flange 11, and above the capping flange, a neck finish 14. The neck finish 14 includes exterior screw threads 15 and abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com