Detonative cleaning apparatus mounting system

a technology of mounting system and cleaning apparatus, which is applied in the direction of cleaning equipment, cleaning hollow objects, light and heating apparatus, etc., can solve the problems of reducing efficiency and throughput, difficult direct access to fouled surfaces, and large industrial equipment surface fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

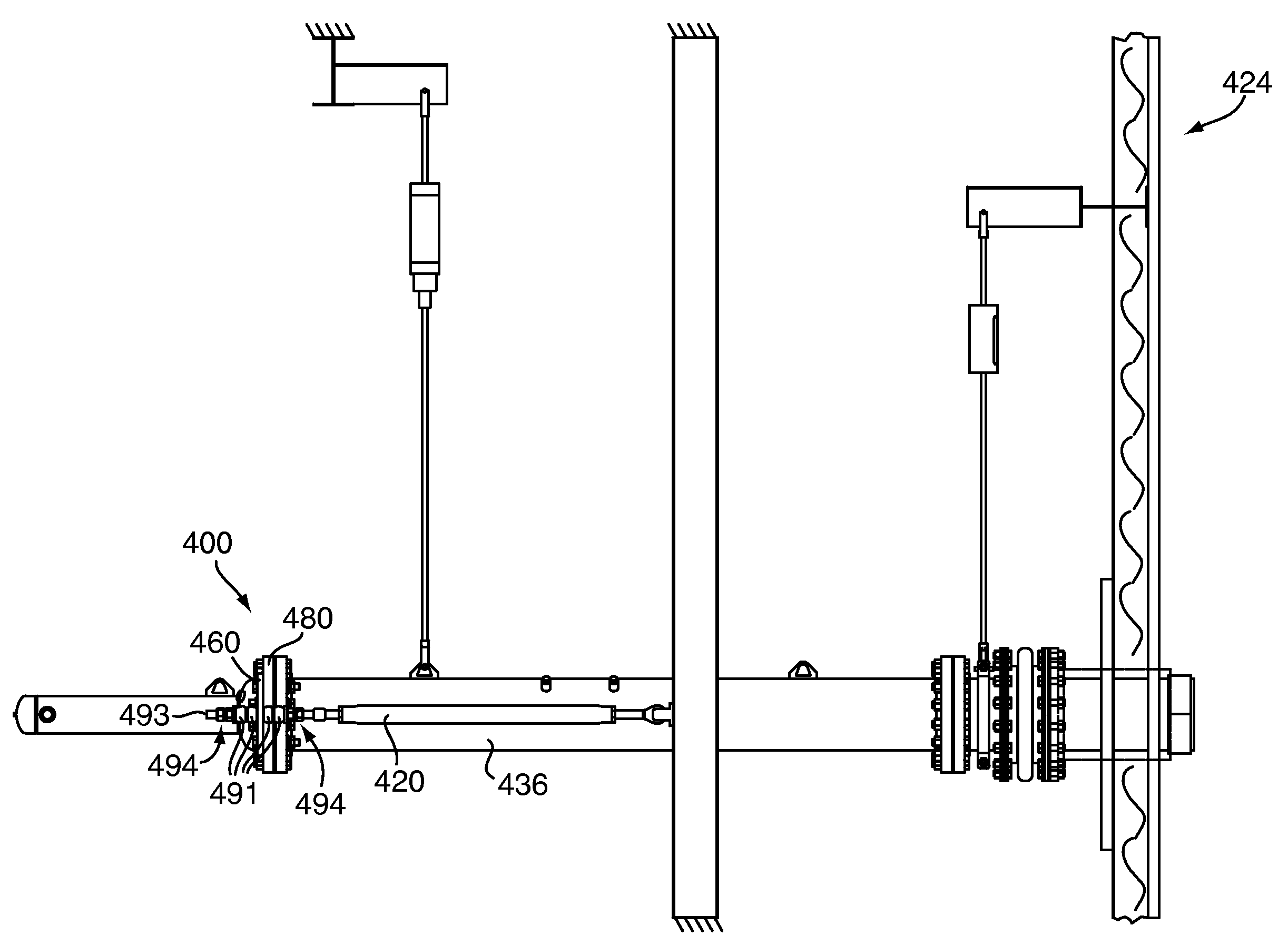

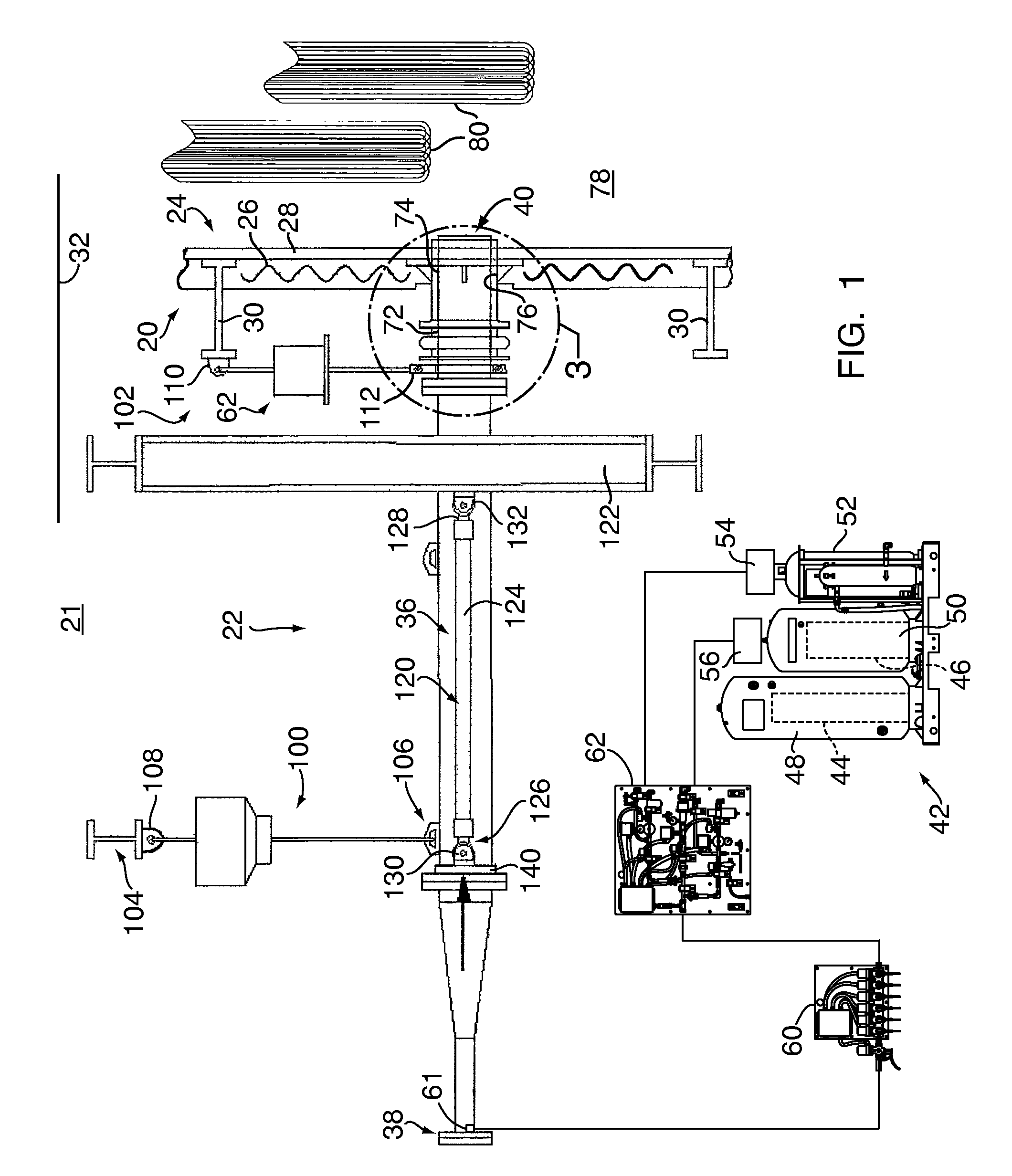

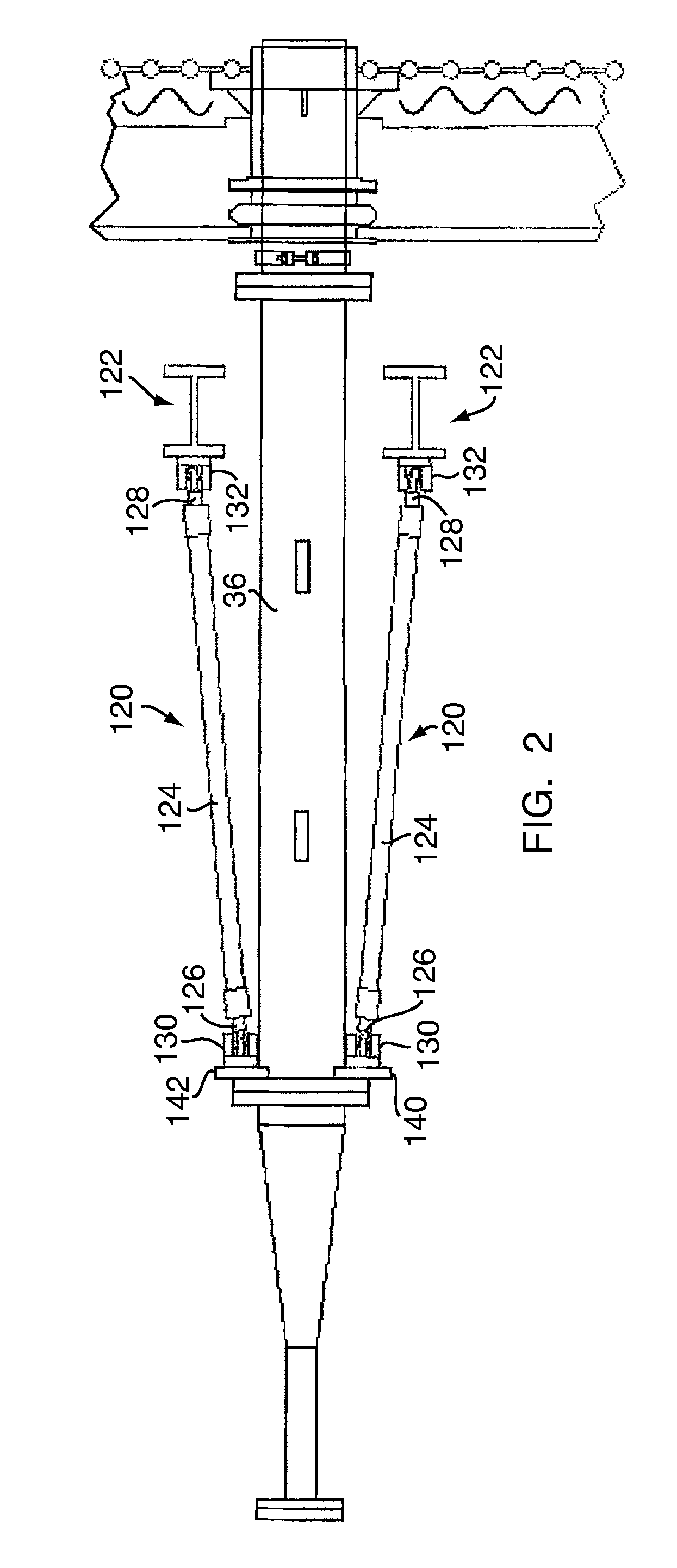

[0033]FIG. 1 shows a vessel (e.g., a boiler) 20 in a building 21. One or more soot blower apparatus (soot blowers) 22 are positioned to clean surfaces within the vessel interior 78. The exemplary vessel comprises a wall 24. The exemplary wall 24 may include a structural and / or insulative outer layer 26 and an inner layer 28. In high temperature locations along the wall 24, the inner layer 28 may be a heat transfer layer formed of fluid (e.g., water)-carrying tubes. Exemplary tubes are welded together to form a membrane wall. In lower temperature locations, the inner layer 28 may be a steel plate. For further structural reinforcement against internal or external pressure loads, the wall 24 may include reinforcements commonly known as buckstays 30. Exemplary buckstays 30 are steel I-beams secured to each other and to the remaining wall structure to form a rigid enclosure. The wall 24 is subject to thermal growth as the vessel temperature increases. The growth may be accommodated by su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com