Method And Apparatus For Abating Fugitive Emissions From A Volatile Liquid Storage Tank

a volatile liquid storage tank and fugitive emission technology, applied in the field of apparatus and a method to abate fugitive emissions from volatile liquid storage tanks, can solve the problems of prohibitively expensive machining close tolerances, difficulty in sealing a conventional floating roof assembly against the interior of a tank that may exceed, and conventional seals that are unusable on large floating roof-equipped tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

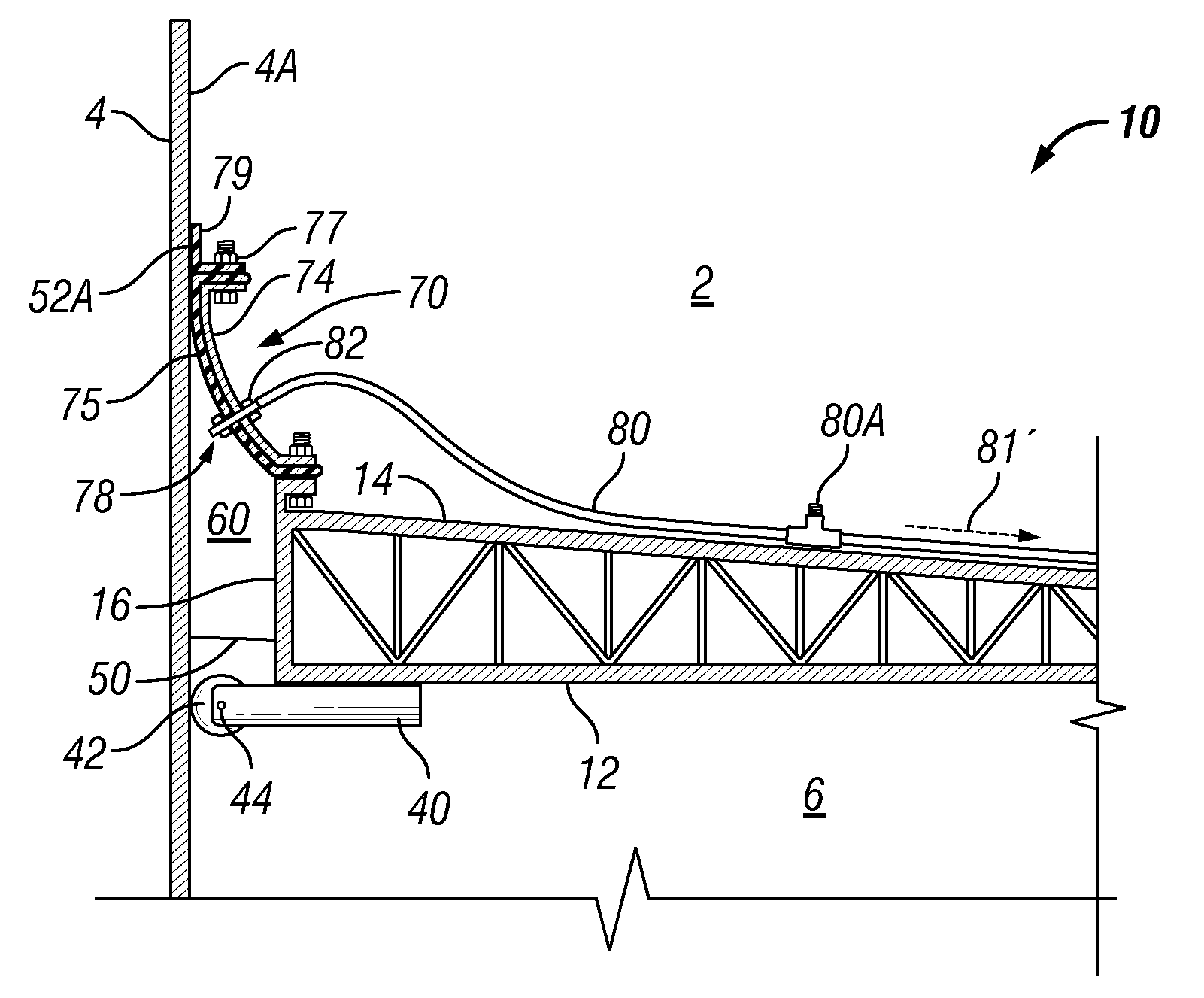

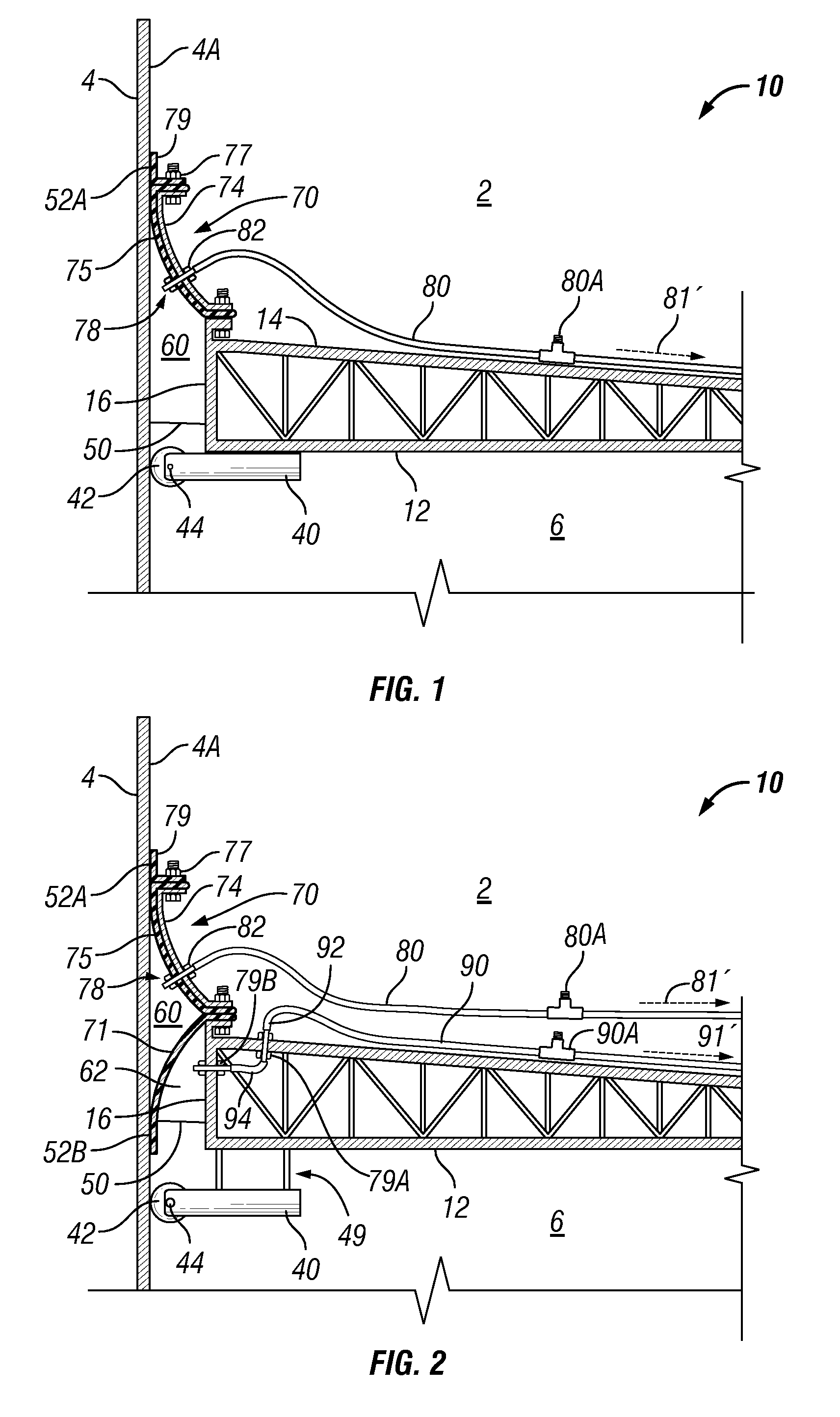

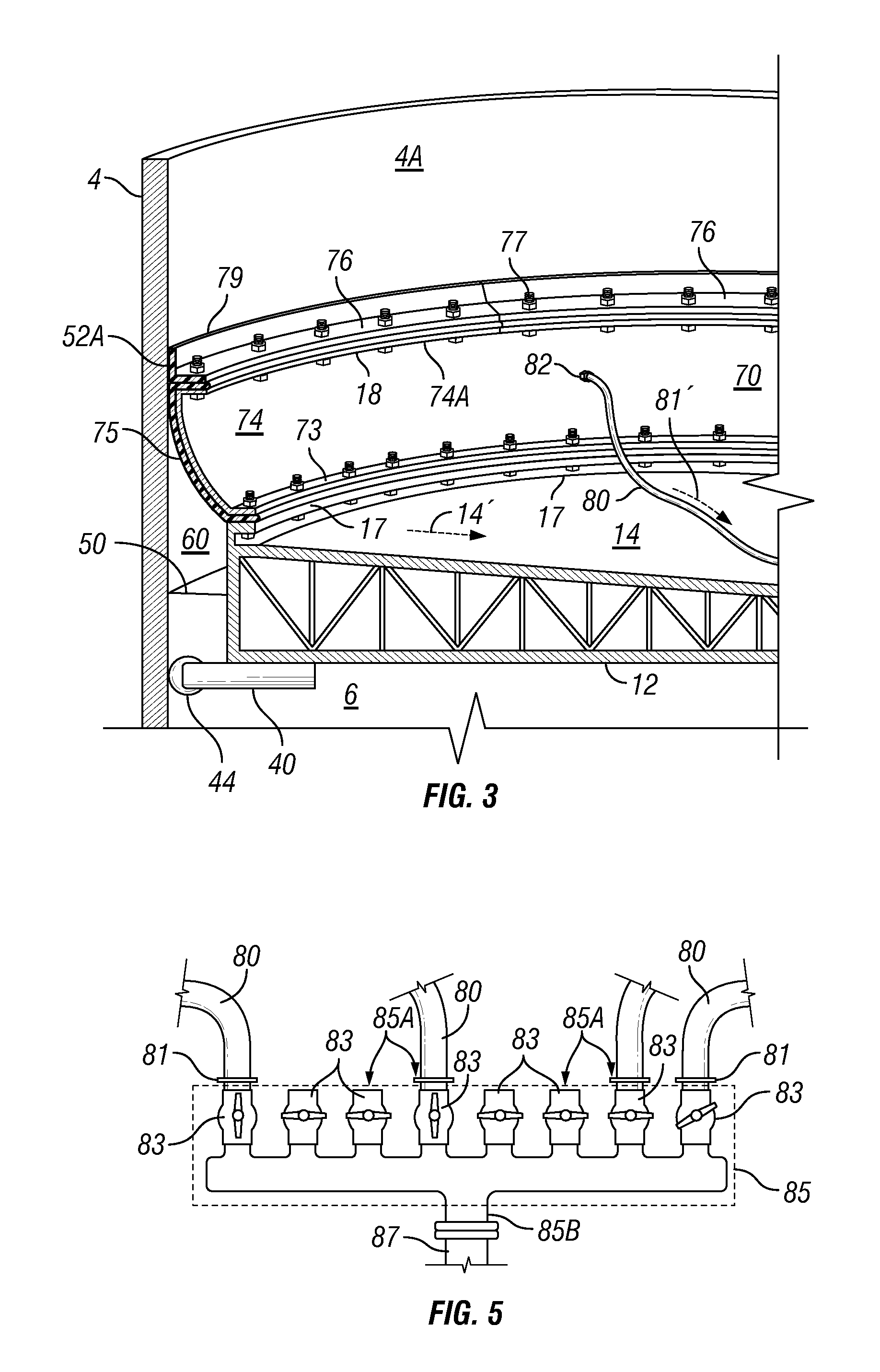

[0020]In one embodiment of the apparatus of the present invention comprises a floating roof assembly comprising a generally disk-shaped buoyant roof structure having a first peripheral seal disposed about its periphery to engage the interior wall of a volatile liquid storage tank and to define an annular gas chamber about the roof structure and generally below the first peripheral seal. The embodiment further comprises at least one aperture penetrating a component of the floating roof tank assembly that is coupled to a first end of at least one fluid conduit. A second end of the at least one fluid conduit is coupled to the inlet to a gas mover, such as a positive displacement compressor or a centrifugal compressor, such as a fan, to continuously withdraw gas from the annular gas chamber.

[0021]As fugitive gas is continuously withdrawn from the annular gas chamber, a small vacuum, preferably less than about 0.15 inches of water, is imparted to the annular gas chamber as a result of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com