Expendable salt core for casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

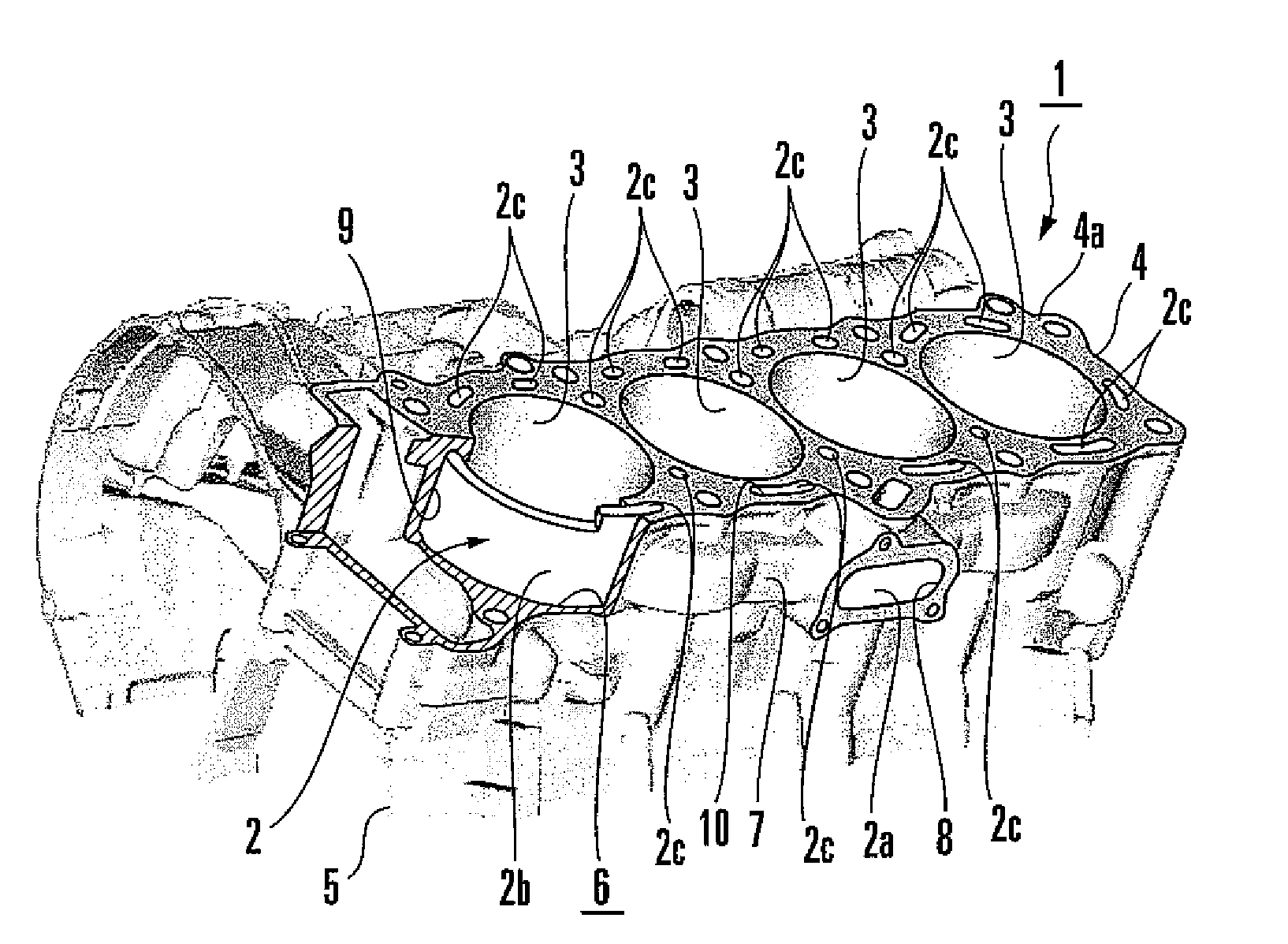

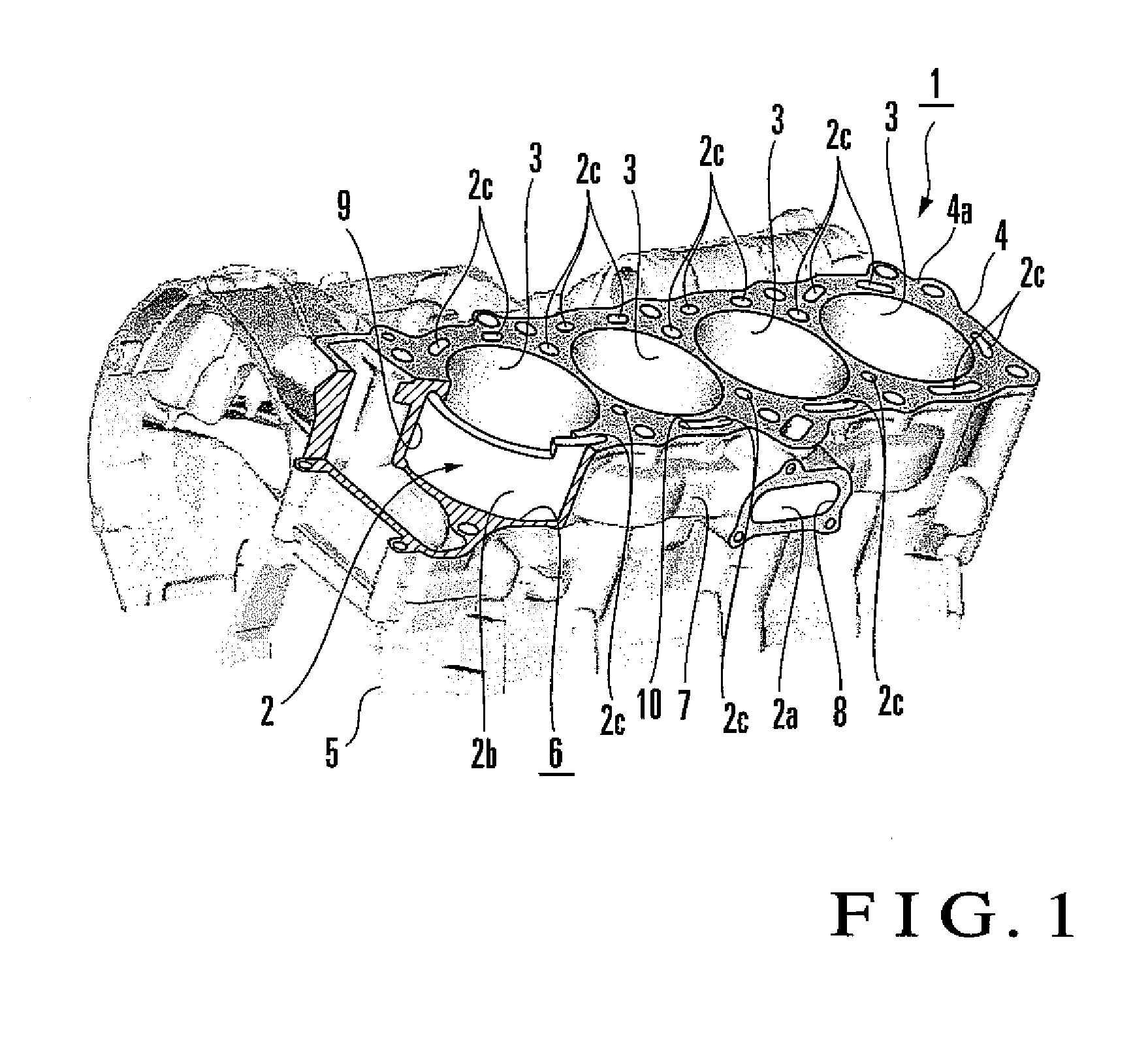

[0024]Preferred embodiments of the present invention will be described hereinafter with reference to the drawings. First, the manner in which an expendable salt core according to a preferred embodiment of the present invention is used will be described with reference to FIG. 1. FIG. 1 is a partially cutaway perspective view of a closed-deck type cylinder block which is cast using the expendable salt core according to a preferred embodiment the present invention. Referring to FIG. 1, reference numeral 1 denotes a closed-deck type cylinder block which is made of, for example, an aluminum alloy and cast using an expendable salt core 2 according to a preferred embodiment of the present invention. The cylinder block 1 is, for example, a portion of a water cooling 4-cycle 4-cylinder engine for a motorcycle which is molded into a predetermined shape by high pressure die casting (HPDC).

[0025]The cylinder block 1 shown in FIG. 1 is integrally provided by four cylinder bores 3, a cylinder bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com