Method of manufacturing a vehicle frame assembly including an integrated hitch having a coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

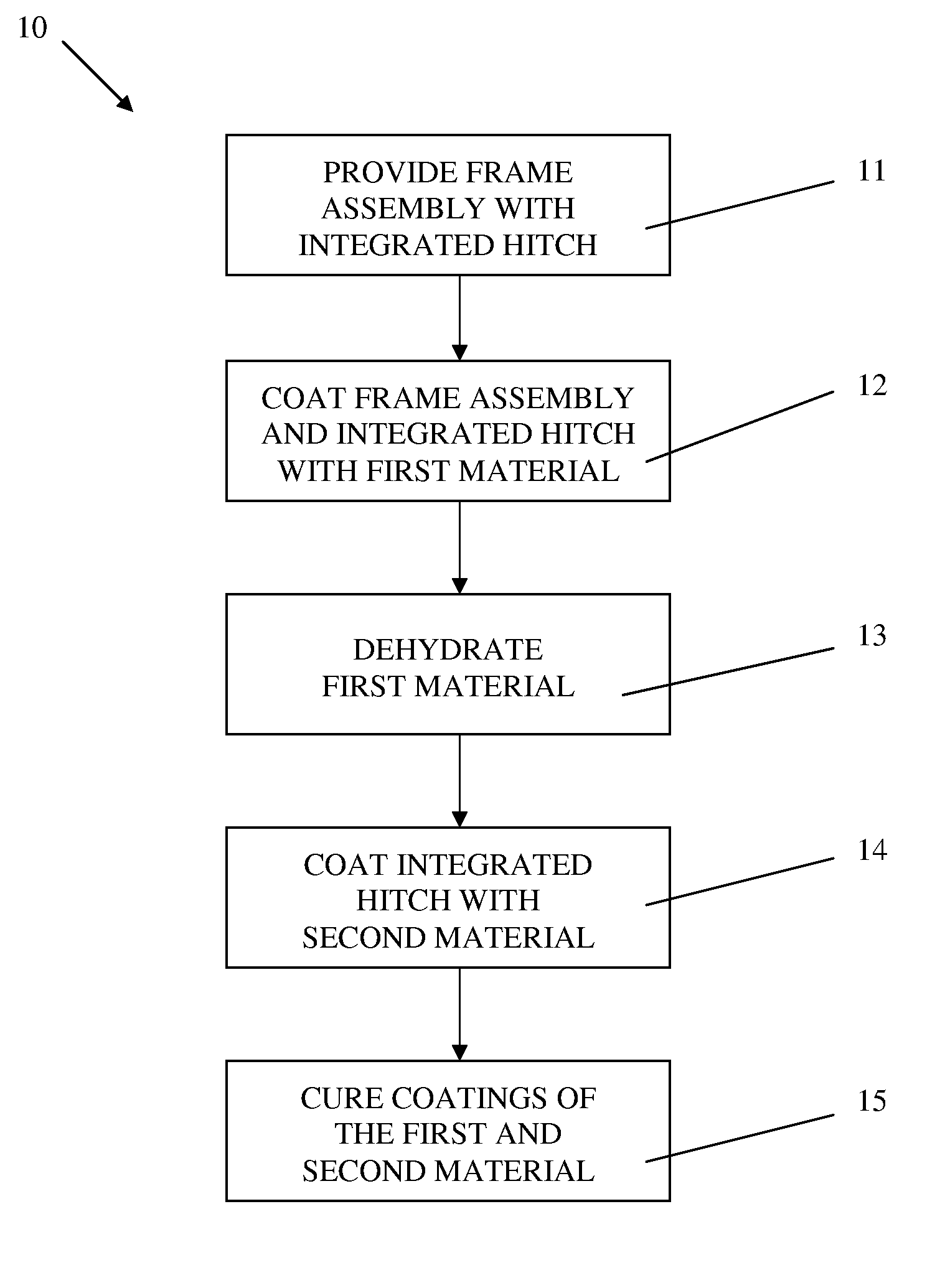

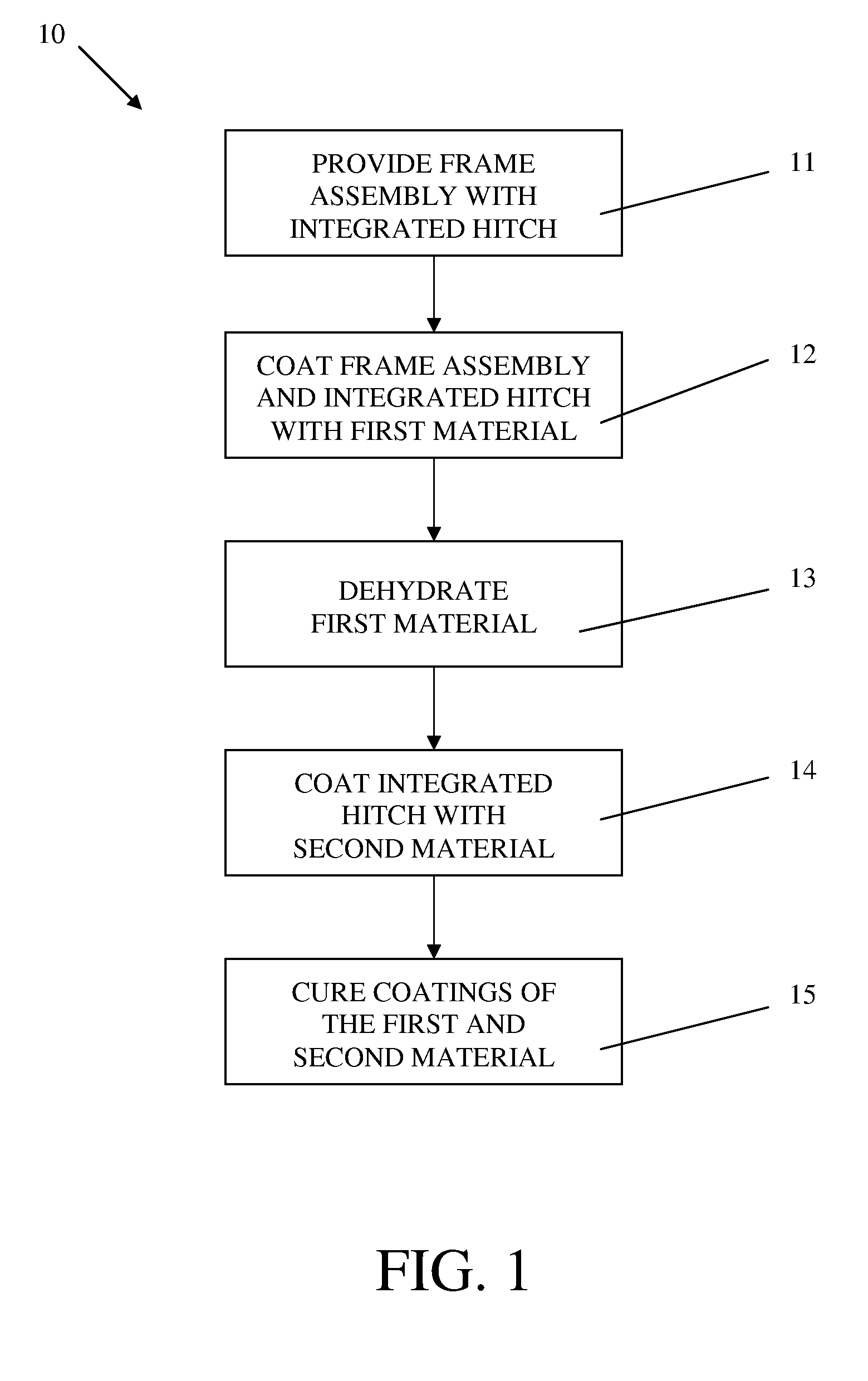

[0011]Referring now to the drawings, there is illustrated in FIG. 1 a flow chart of a method, indicated generally at 10, of manufacturing a vehicle frame assembly including an integrated hitch having a coating of a material provided thereon in accordance with this invention. Although this invention will be described and illustrated in the context of a vehicle frame assembly including an integrated hitch, it will be appreciated this invention may be practiced in any desired environment in the manner described below.

[0012]In a first step 11 of the method 10 of this invention, a vehicle frame assembly including an integrated hitch is provided. This can be accomplished in any desired manner. Typically, a plurality of structural components is initially provided, and at least one of such structural components is or includes a hitch. These structural components can be formed from a single material or from a plurality of materials as desired. Typically, the structural components are formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com