Method of manufacturing flexible, lightweight photovoltaic array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

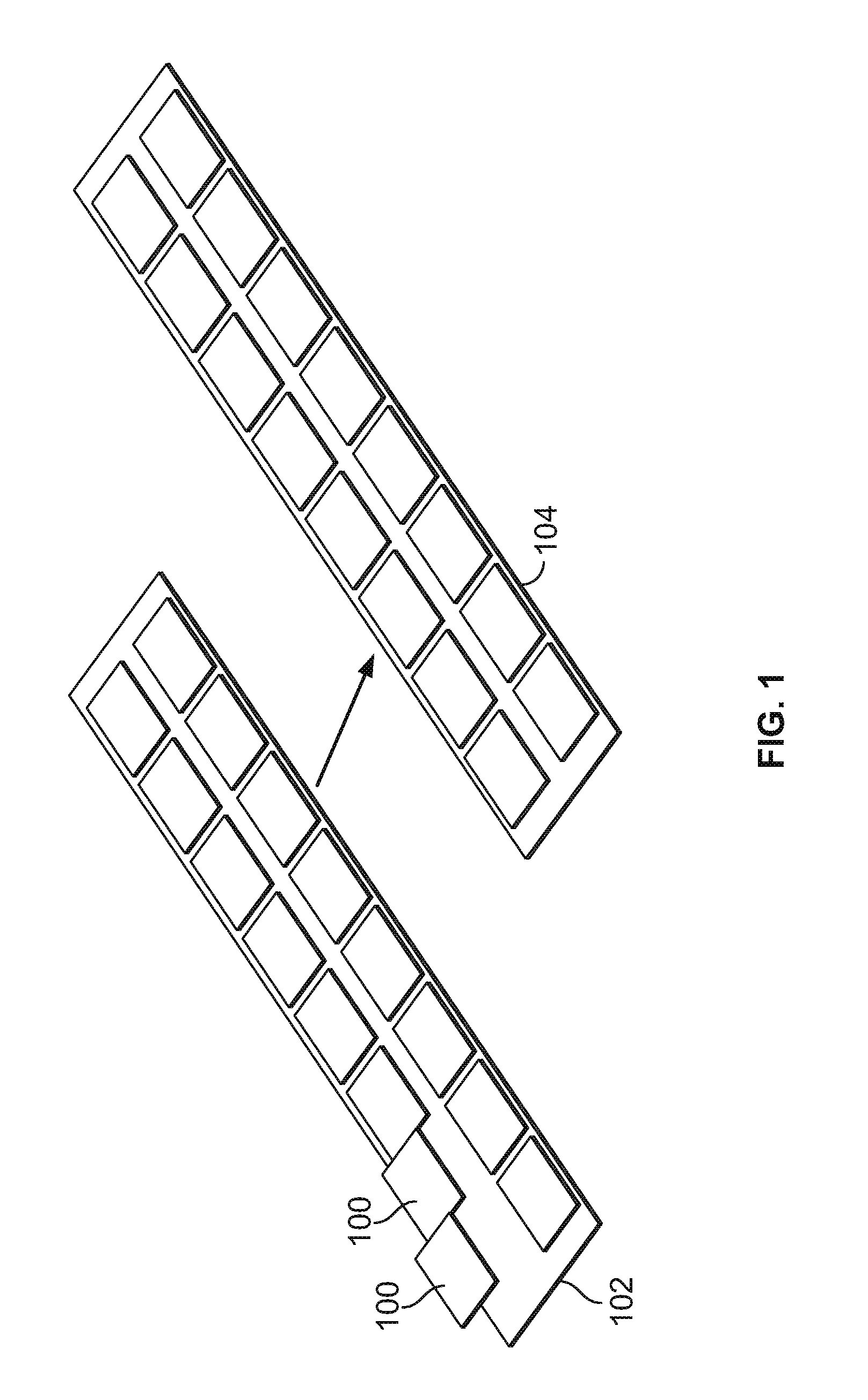

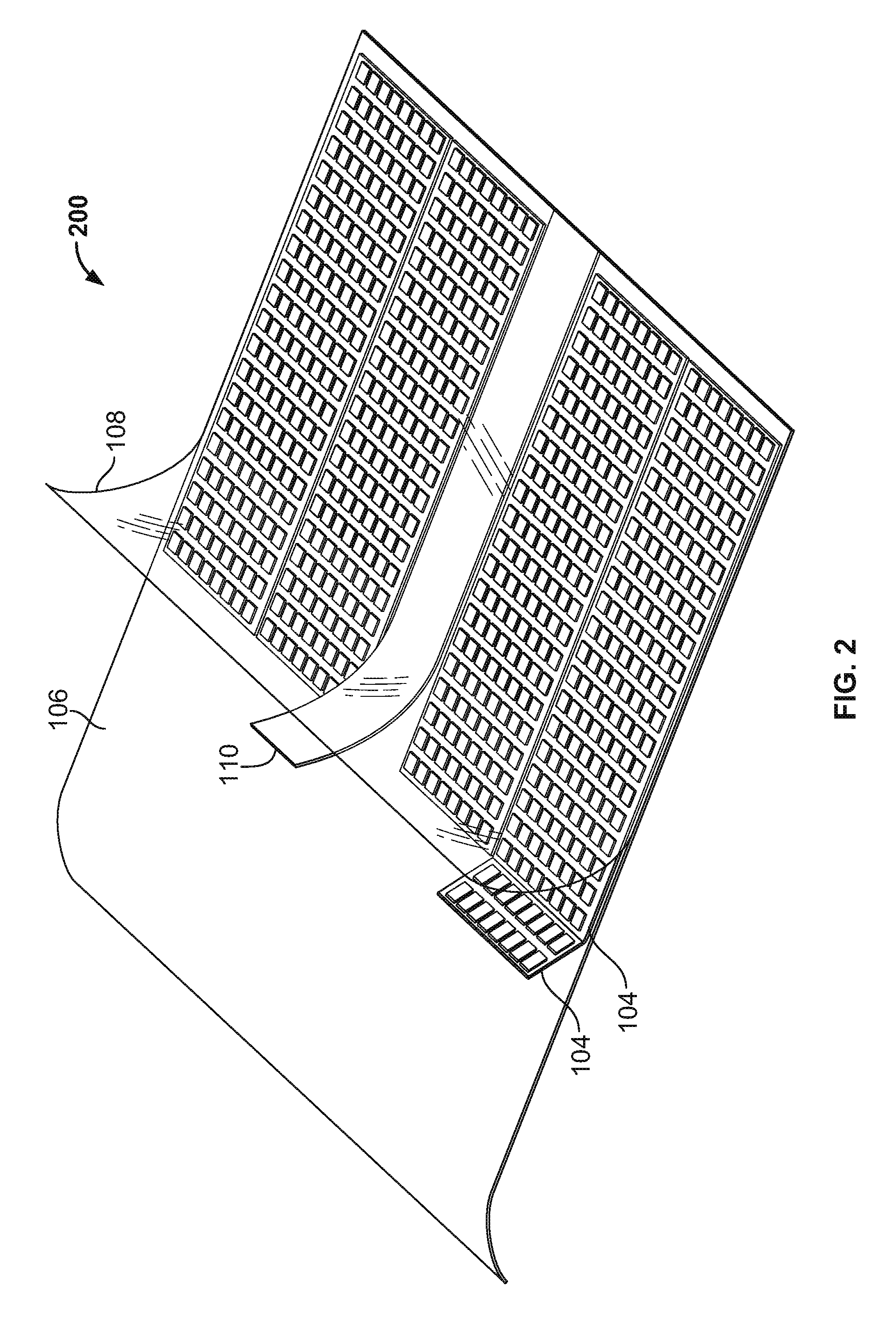

[0016]To provide an overall understanding of the invention, certain illustrative embodiments will now be described, including a flexible lightweight photovoltaic array and a method for manufacturing the photovoltaic array. However, it will be understood by one of ordinary skill in the art that the systems and methods described herein may be adapted and modified as is appropriate for the application being addressed and that the systems and methods described herein may be employed in other suitable applications, and that such other additions and modifications will not depart from the scope hereof.

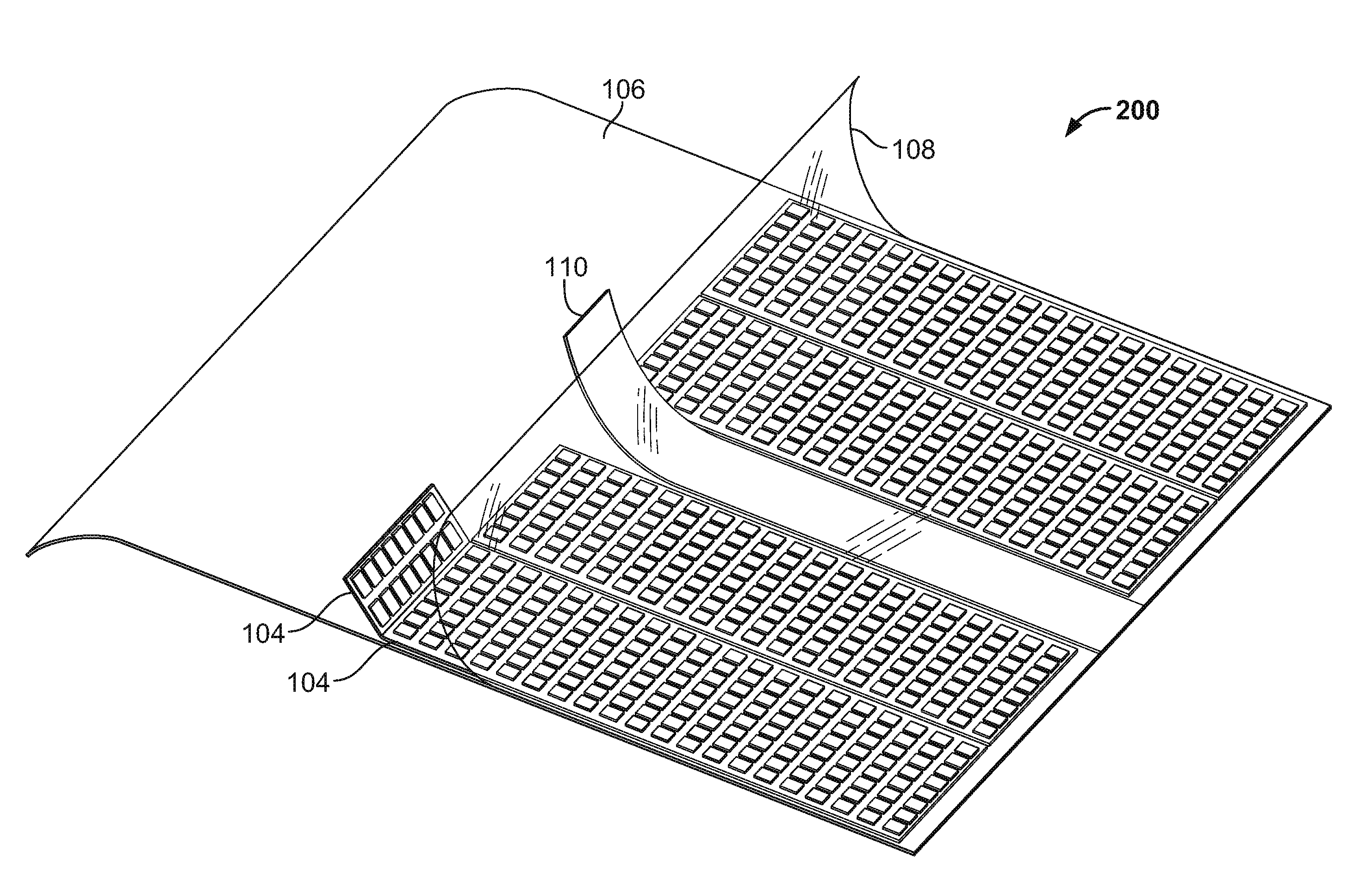

[0017]Individual photovoltaic cells are connected in series so as to obtain a desired voltage, according to characteristics of the photovoltaic cells, to create photovoltaic cell strings. The photovoltaic cell strings are then connected in parallel so as to obtain a desired output capacity, thus creating a photovoltaic cell array. FIG. 1 shows the assembly of individual photovoltaic cell stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

| Emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com