Led chip package structure using sedimentation and method for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

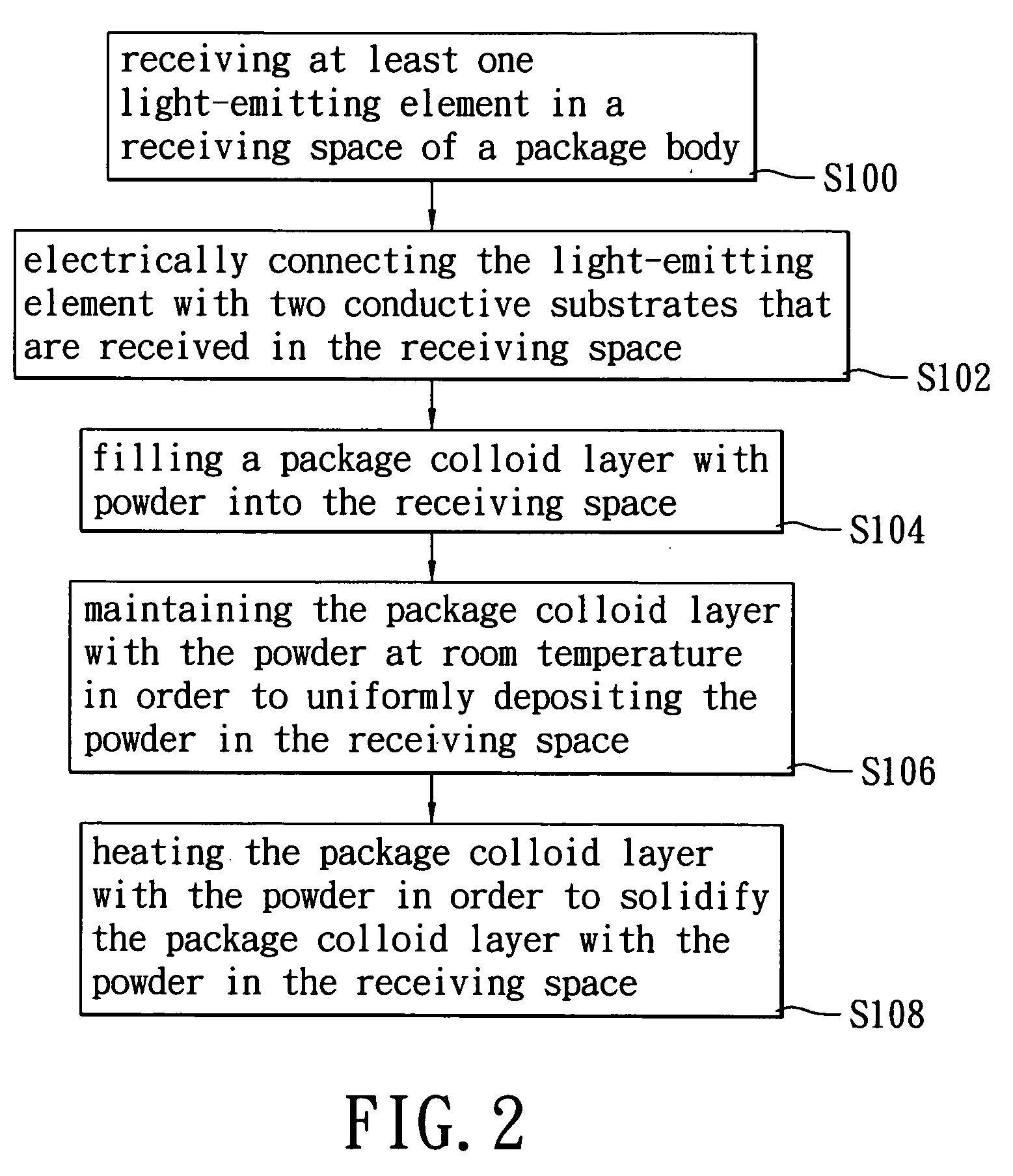

[0034]Referring to FIGS. 2 and 2A to 2C, the present invention provides a method for making an LED chip package structure using sedimentation, including the following steps:

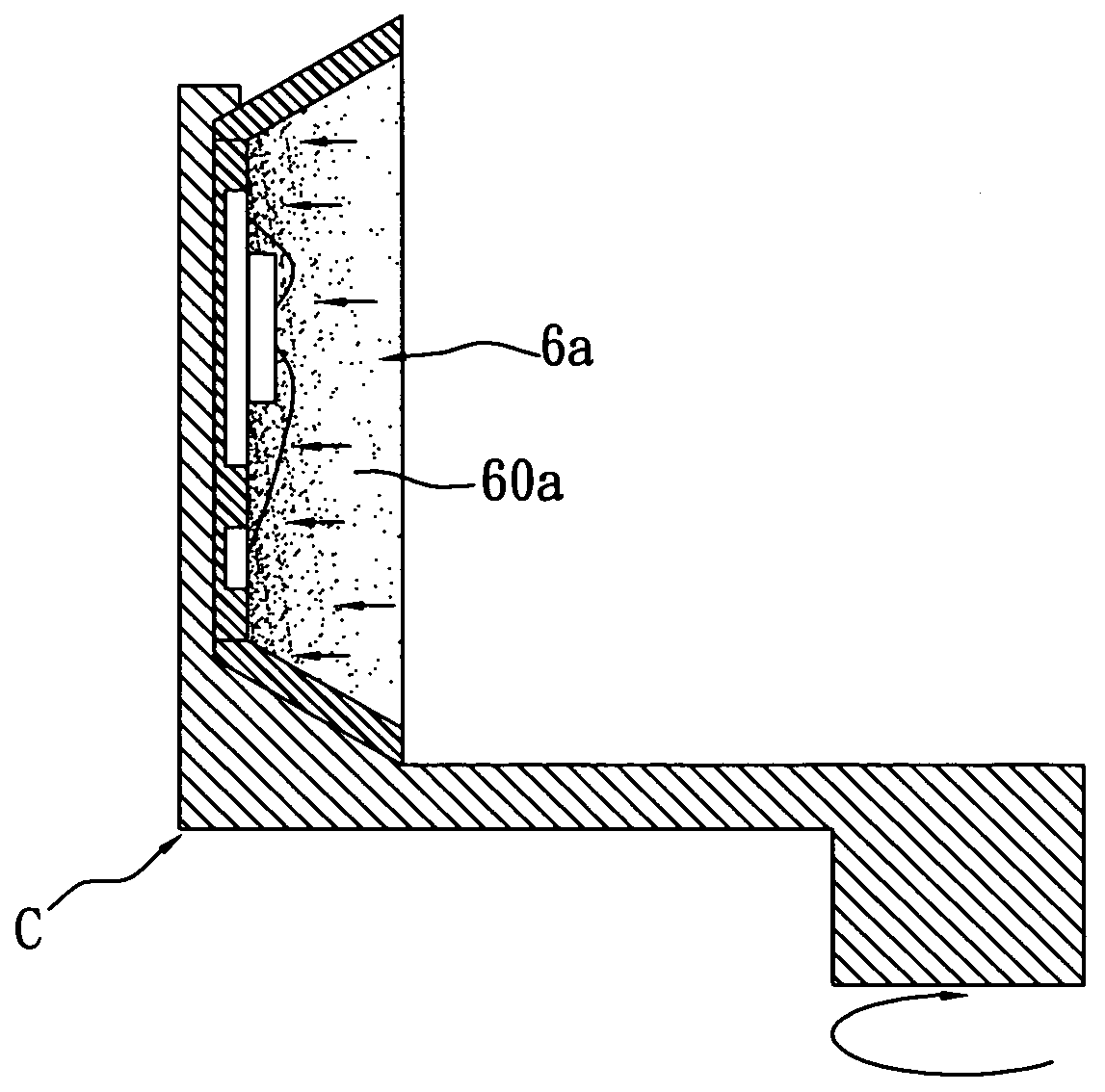

[0035]Step S100 is: referring to FIGS. 2 and 2A, receiving at least one light-emitting element la in a receiving space 20a of a package body 2a. In the first embodiment, the light-emitting element la can be a blue LED, and the package body 2a has a bowl shape. In addition, the light-emitting element 1a is firmly fixed on the inner surface of the bowl-shaped package body 2a via a chip-positioning layer 3a formed between the light-emitting element 1a and the package body 2a. Moreover, the chip-positioning layer 3a is solidified by curing to 155° C. during 3 hours in order to firmly fix the light-emitting element 1a on the inner surface of the bowl-shaped package body 2a.

[0036]Step S102 is: referring to FIGS. 2 and 2A, electrically connecting the light-emitting element 1a with two conductive substrates (40a, 41a) t...

second embodiment

[0045]Moreover, after the step of S202, the present invention further includes the following steps:

[0046]Step S204 is: referring to FIGS. 3 and 3A, filling a package colloid layer 6b with powder 60b into one part of a receiving space 20b of a package body 2b.

[0047]Step S206 is: referring to FIGS. 3 and 3B, maintaining the package colloid layer 6b with the powder 60b at room temperature in order to uniformly depositing the powder 60b′ in one part of the receiving space 20b. In other words, the powder 60b′ can be deposited on a light-emitting element 1b, two conductive substrates (40b, 41b) and an inner surface of the package body 2b. In addition, the room temperature is defined as 13-25° C., and the package colloid layer 6b is maintained at 1-168 hours according the properties of the package colloid layer 6b.

[0048]Step S208 is: heating the package colloid layer 6b′ with the powder 60b′ in order to solidify the package colloid layer 6b′ with the powder 60b′. In other words, the pack...

third embodiment

[0053]Moreover, after the step of S302, the present invention further includes the following steps:

[0054]Step S304 is: referring to FIGS. 4 and 4A, filling a transparent colloid layer 7c into one part of a receiving space 20c of a package body 2c in order to cover at least one light-emitting element 1c.

[0055]Step S306 is: heating the transparent colloid layer 7c to 80-150° C. during 1-6 hours in order to solidify the transparent colloid layer 7c.

[0056]Step S308 is: referring to FIGS. 4 and 4B, filling a package colloid layer 6c with powder 60c in the other part of the receiving space 20c of the package body 2c in order to form the package colloid layer 6c with the powder 60c on the transparent colloid layer 7c.

[0057]Step S310 is: referring to FIGS. 4 and 4C, maintaining the package colloid layer 6c with the powder 60c at room temperature in order to uniformly depositing the powder 60c′ on the transparent colloid layer 7c. In addition, the room temperature is defined as 13-25° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com