Methods of forming polycrystalline diamond cutters

a technology of polycrystalline diamond and composites, applied in the direction of manufacturing tools, other chemical processes, chemistry apparatus and processes, etc., can solve the problems of short cutter operating life, cracking or exfoliation of cutting tables, and sputtering, and achieve the effect of shortening the operating life of cutters, cracking or exfoliation of cutting tables, and fracturing partial fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

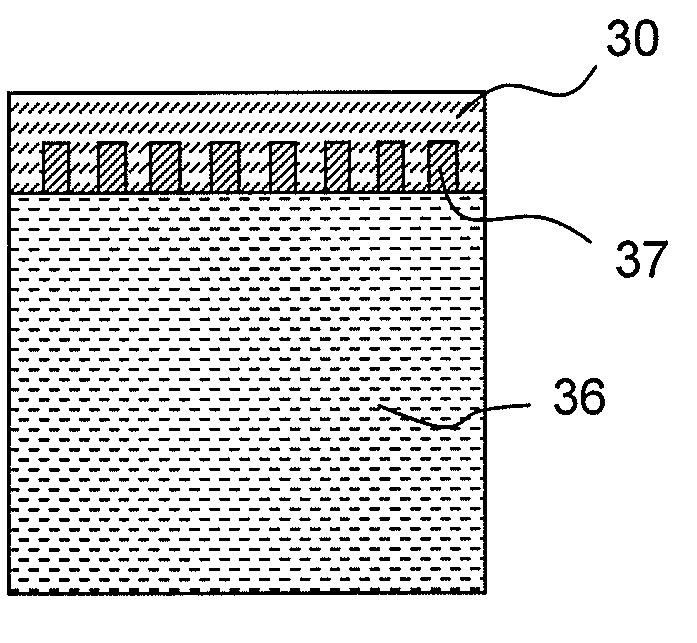

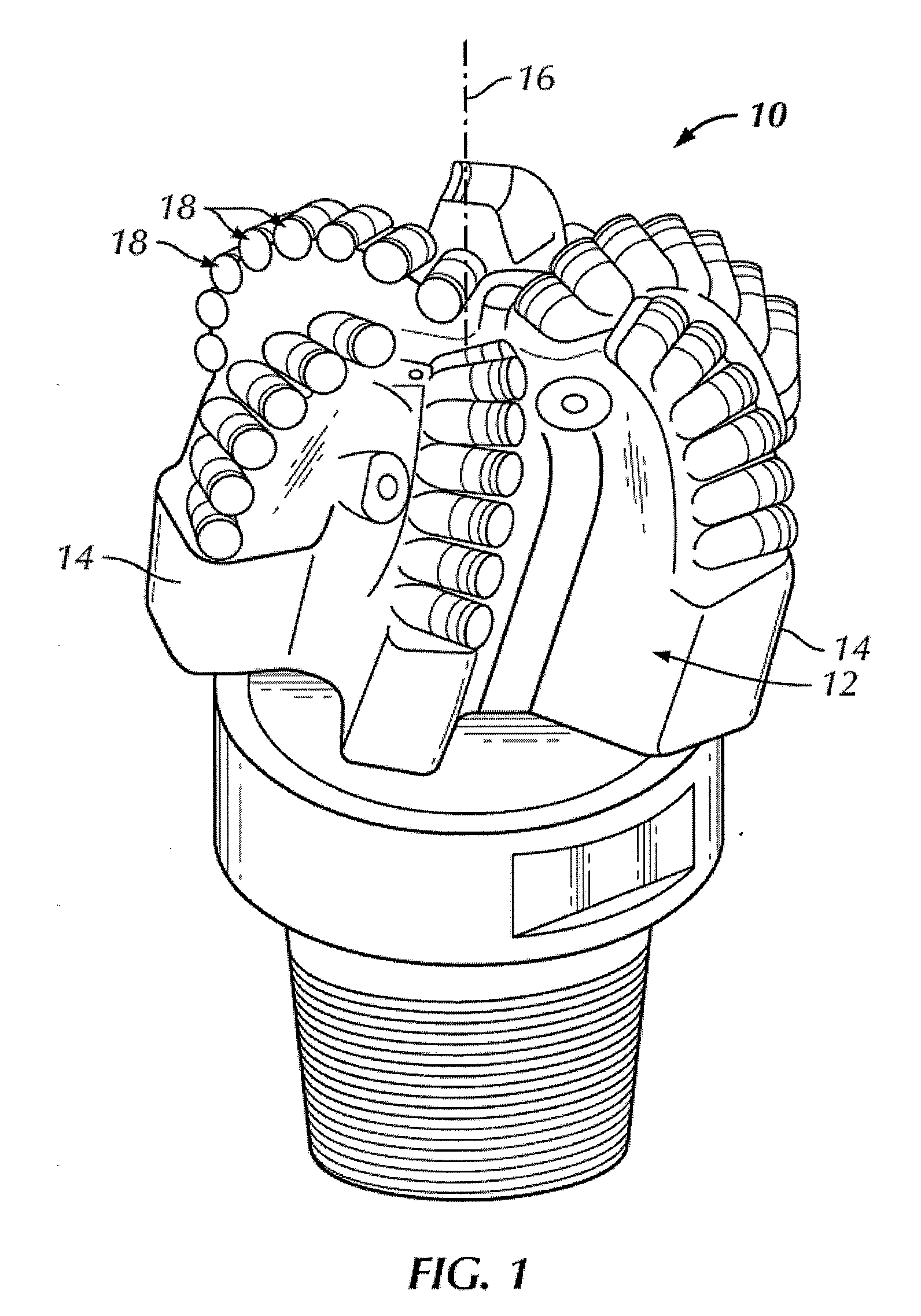

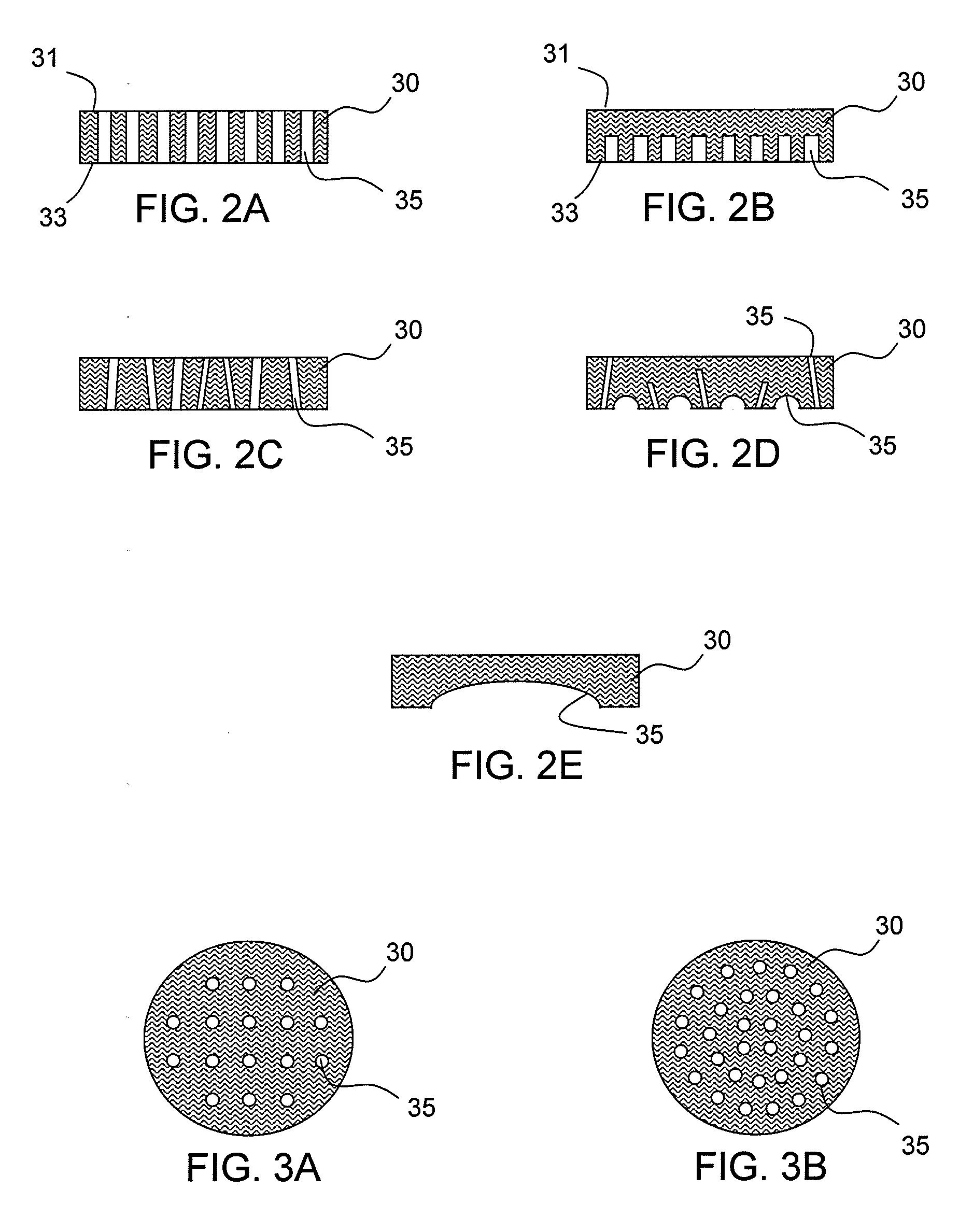

[0026]In one aspect, embodiments disclosed herein relate to polycrystalline diamond (or other polycrystalline abrasive bodied) cutting elements and methods of forming non-planar interfaces between the polycrystalline diamond layer and a substrate. More specifically, embodiments disclosed herein are directed to non-planar interfaces resulting from forming cavities in a polycrystalline abrasive body and attaching the body to a substrate.

[0027]As used herein, the term “PCD” refers to polycrystalline diamond that has been formed, at high pressure / high temperature (HPHT) conditions, through the use of a solvent metal catalyst, such as those included in Group VIII of the Periodic table. However, the present disclosure is also directed to polycrystalline cubic boron nitride (formed from subjecting boron nitride particles to HPHT conditions) as well as thermally stable polycrystalline diamond. The term “thermally stable polycrystalline diamond,” as used herein, refers to intercrystalline bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com