Trailer mounted crash attenuator

a technology of attenuator and trailer, which is applied in the field of attenuators, can solve the problems of not preventing the attenuator from rotating, requiring skilled labor, welders and machinists, and attaching directly to the truck fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

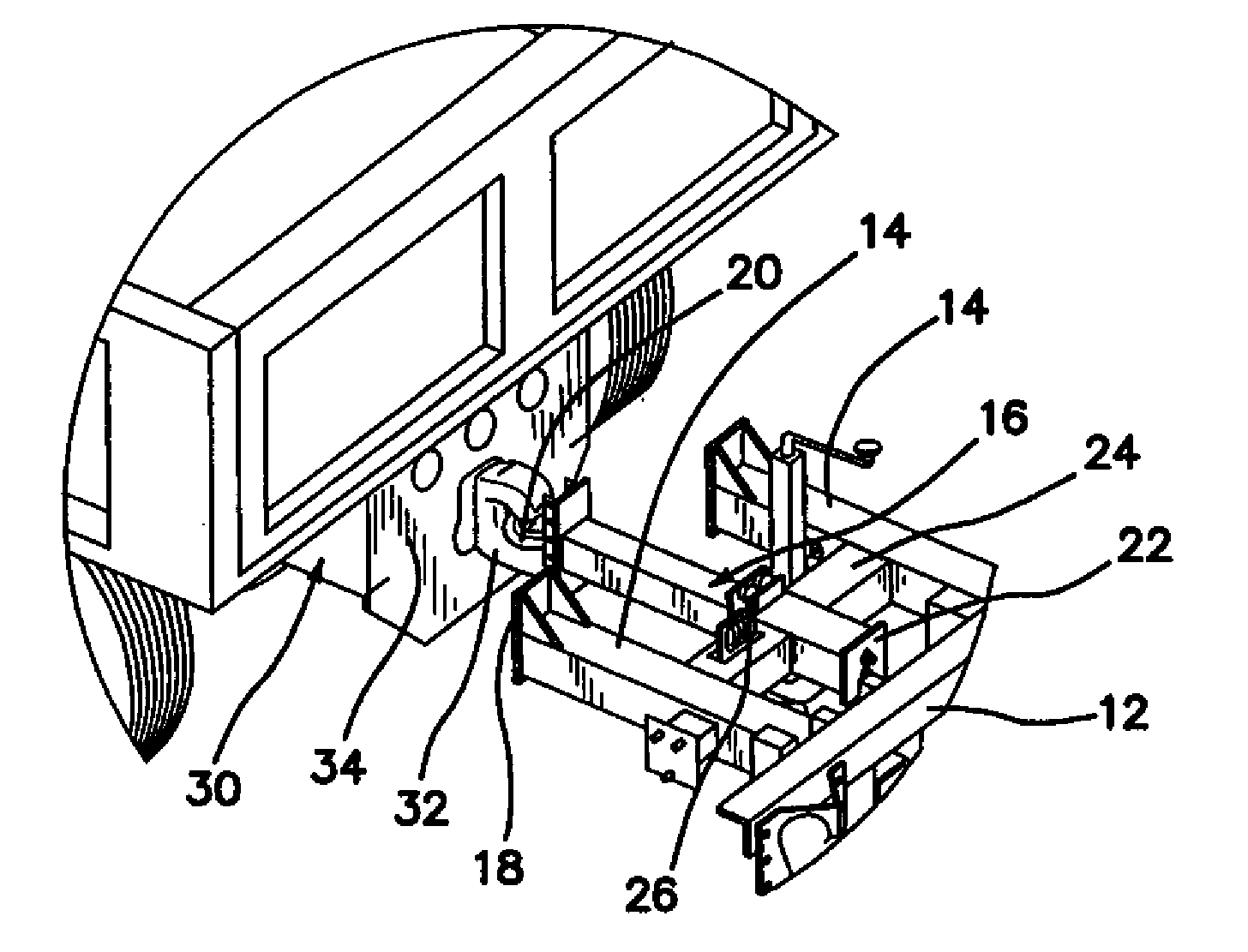

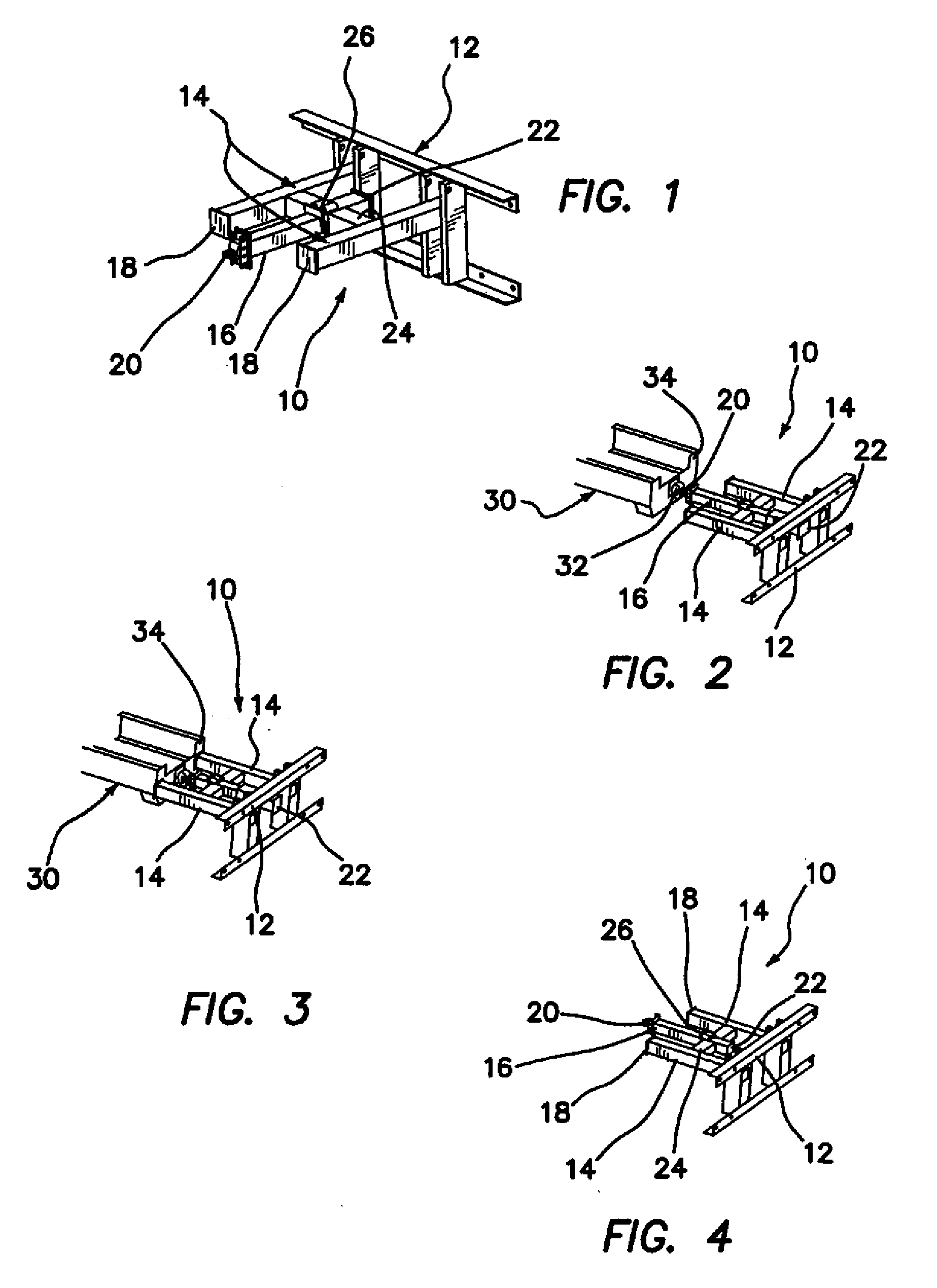

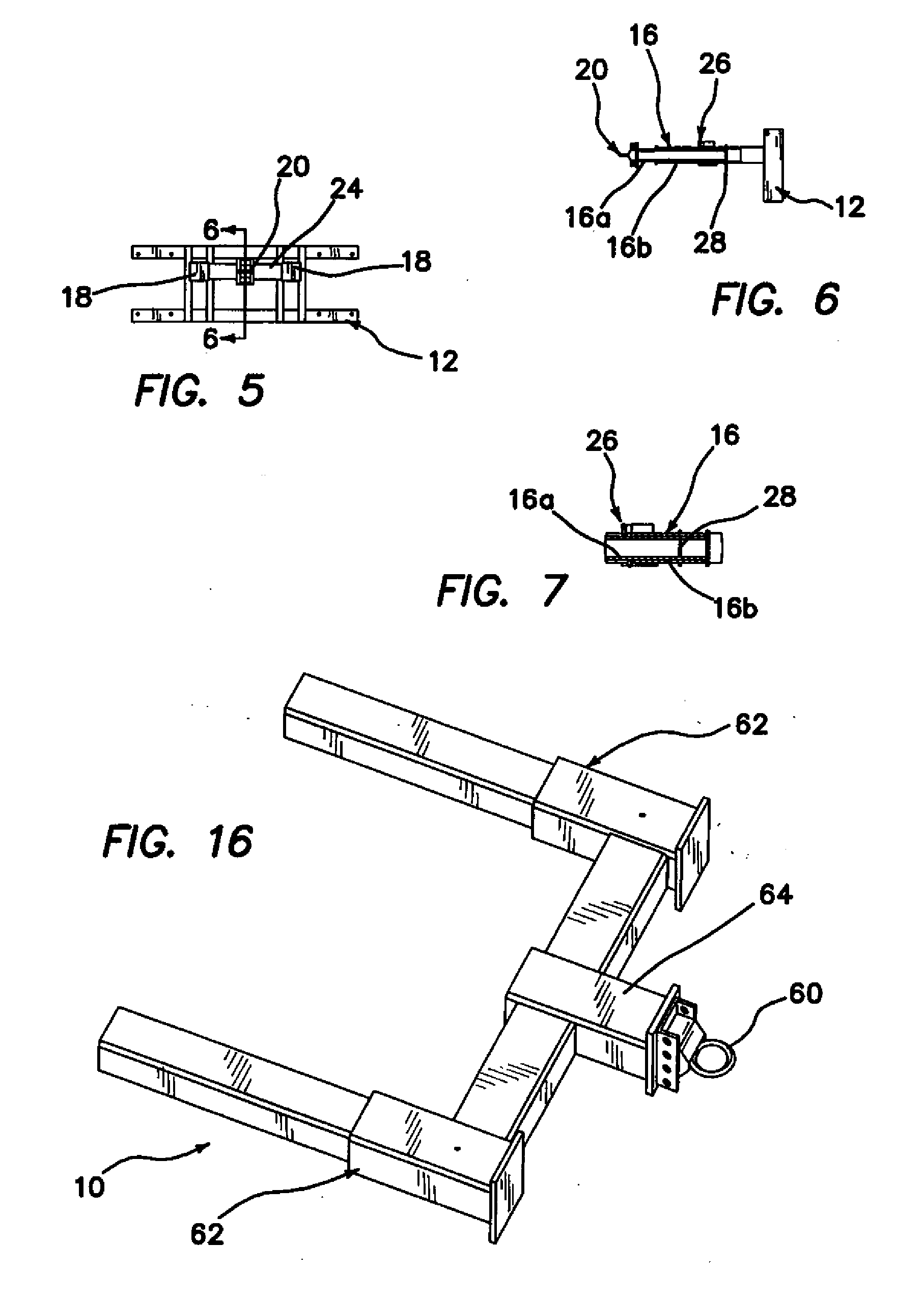

[0043]Referring now to the figures, wherein like reference numerals refer to like elements throughout the figures, there is shown in FIG. 1 a telescoping anti-rotation attachment system 10 constructed in accordance with the principles of the present invention. The system 10 comprises a backup frame 12, a pair of external anti-rotation support tubes 14, and an internal telescoping support tube 16.

[0044]Anti-rotation support pads 18 are disposed on the distal end of each of the external anti-rotation support tubes 14, and an adjustable eye assembly 20 is disposed on the distal end of the internal telescoping support tube 16.

[0045]The trailer attachment system 10, in a preferred embodiment, is made of A-36 steel and weights approximately 660 lbs. The overall dimensions are approximately 25 in.×54 3 / 16 in.×74 in. During normal operation, the system 10 attaches to a pintle hook on a truck, using the eye assembly 20, which in one embodiment comprises a 3 in. lunette eye. This eye is a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com