Flow rate ratio control device

a flow rate ratio and control device technology, applied in water supply installation, process and machine control, instruments, etc., can solve the problems of unstable inability to reach the target pressure, and considerable time, so as to improve the control response, shorten the control stop period of the control valve, and improve the transient performance of branch flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]One embodiment of the present invention will hereinafter be described referring to the drawings.

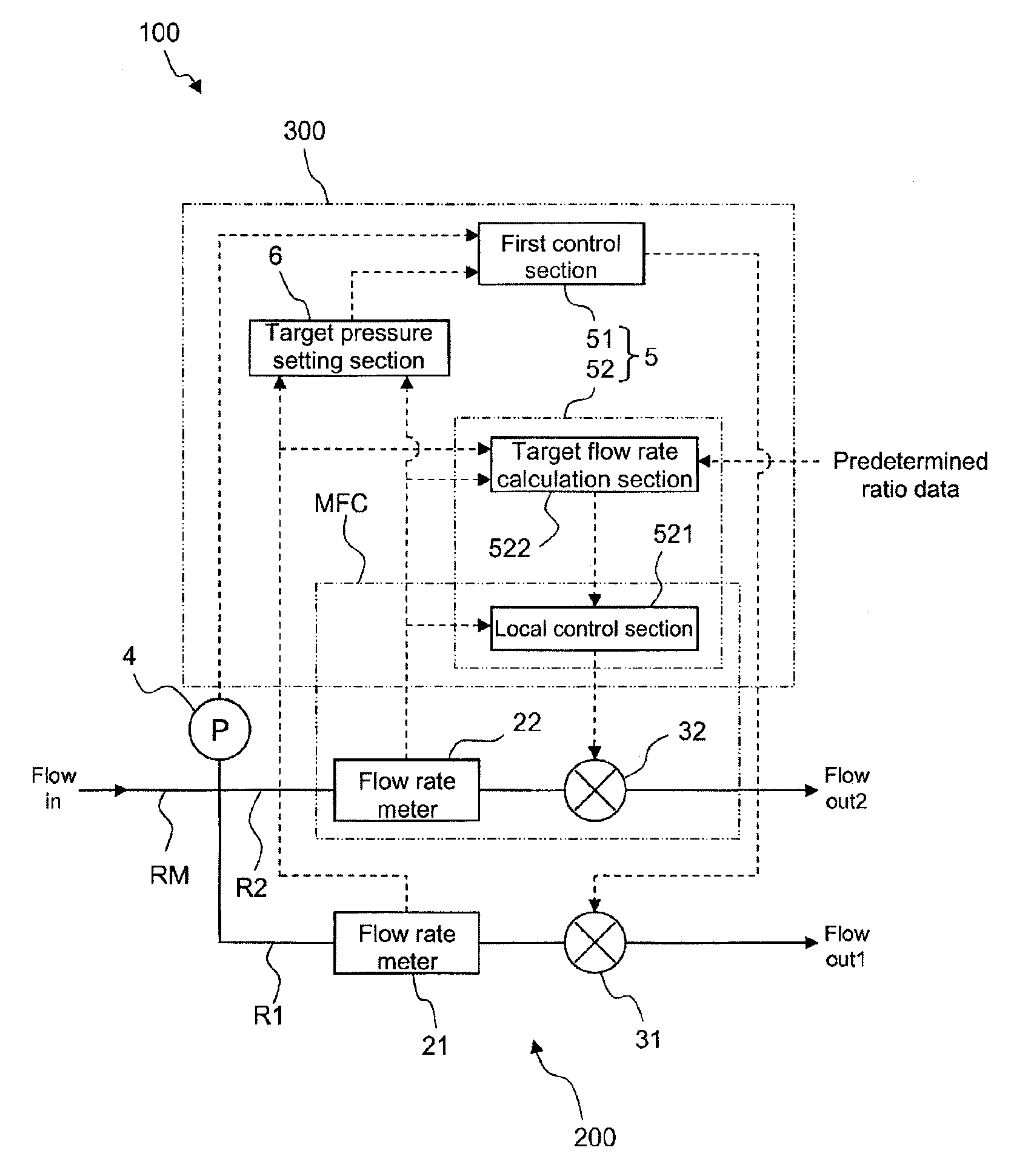

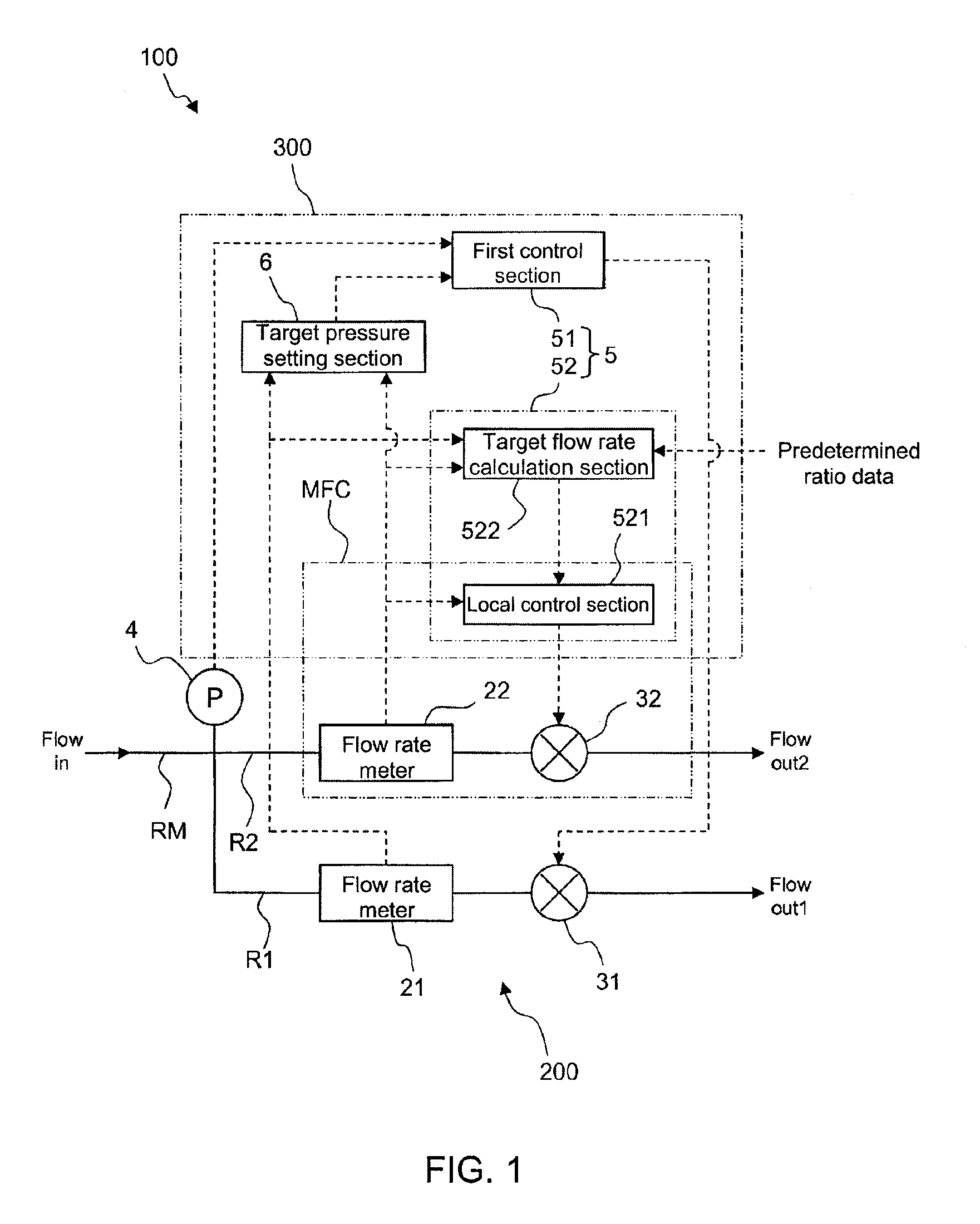

[0025]FIG. 1 is a schematic diagram illustrating a flow rate ratio control device 100 according to the present embodiment. The flow rate ratio control device 100 is a device for branching a flow of, for example, source gas for semiconductor manufacturing at a predetermined ratio to supply the gas to a semiconductor processing chamber, and constitutes a part of an unshown semiconductor manufacturing system. The device 100 mainly includes a fluid circuit mechanism 200, and a control mechanism 300 for controlling the fluid circuit mechanism 200.

[0026]The fluid circuit mechanism 200 is a mechanism having the same configuration as that of the above-described conventional device, and includes a main channel RM into which fluid to be branched flows, and two branch channels R1 and R2 that branch from an end part of the main channel RM. The fluid to be introduced into the main channel RM is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com