Strapping System and Method to Reinforce Framed Structures

a technology of framed structures and reinforced beams, applied in the direction of buildings, construction, building repairs, etc., can solve the problems of interiors and structures often damaged, subject to significant damage, and most structures have relatively poor inherent resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

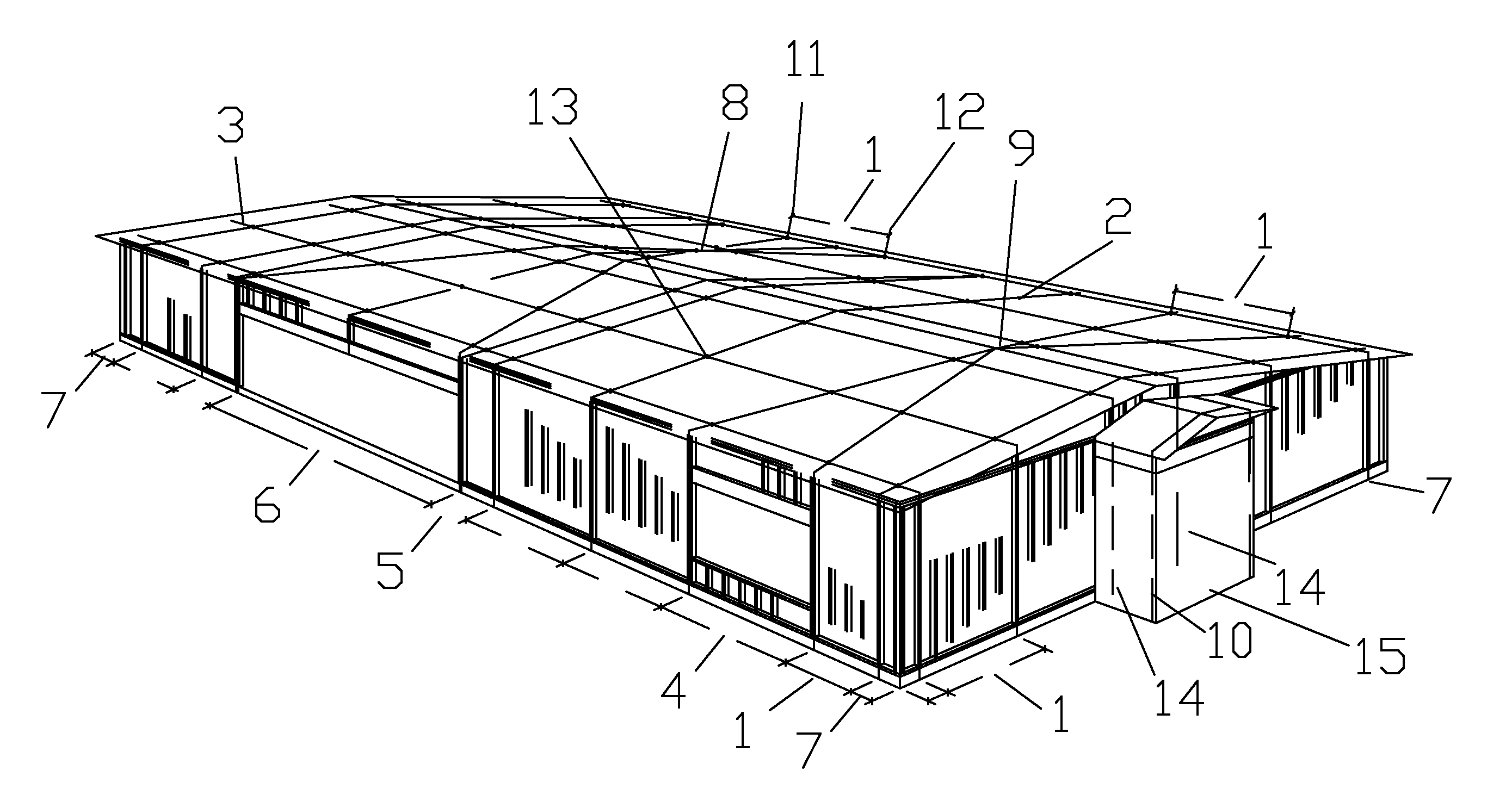

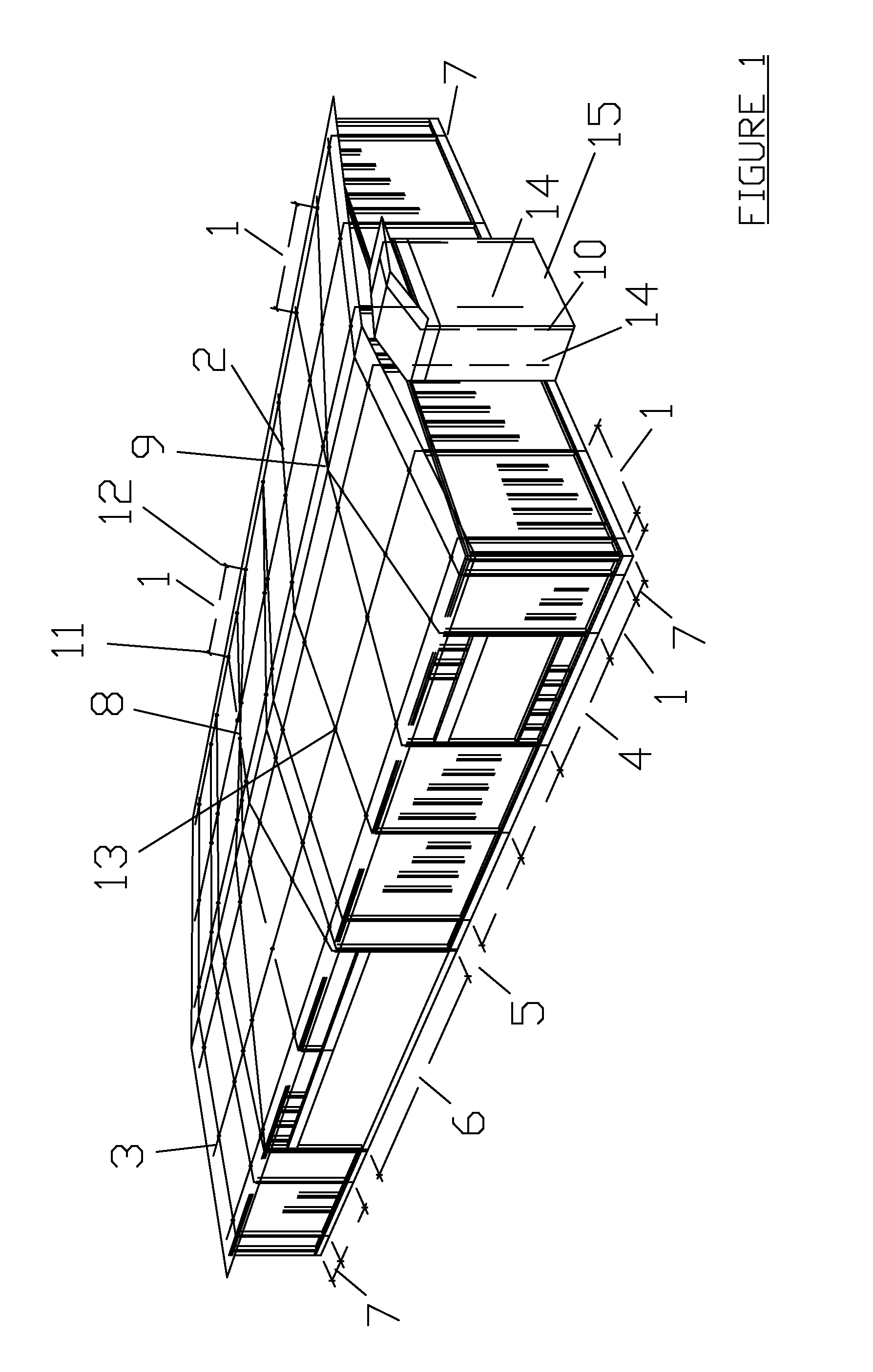

[0024]In reference to FIG. 1, a standard 4-sided structure with an angled roof and eave is shown with the strapping system of the present invention in place. Item 1 represents the standard strap spacing determined by the installer based upon the degree of resistance desired or required by local Building Codes. The inventors have determined that 3 to 10 feet spacing will be adequate for most Code requirements and external forces to be expected in the United States. The shorter the standard spacing, more straps will be present for a given building dimension and greater structural resistance will result. For example, 3-feet spacing may be required to protect a structure directly on the coast, which may be subject to the highest wind force of a hurricane. However, greater standard spacing may be desired further inland as hurricane winds tend to decrease once the storm moves further over land.

[0025]The strapping system of this typical structure is designed by first locating the end-wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com