Linear solar energy collection system

a solar energy collection and solar energy technology, applied in the direction of solar heat collector mounting/support, solar heat collector safety, light and heating equipment, etc., can solve the problems of difficult installation, heavy mirrors, and poor solar field efficiency of the type described above, so as to reduce the overall cost of generating electricity per kilowatt hour, improve solar field efficiency, and reduce operational and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

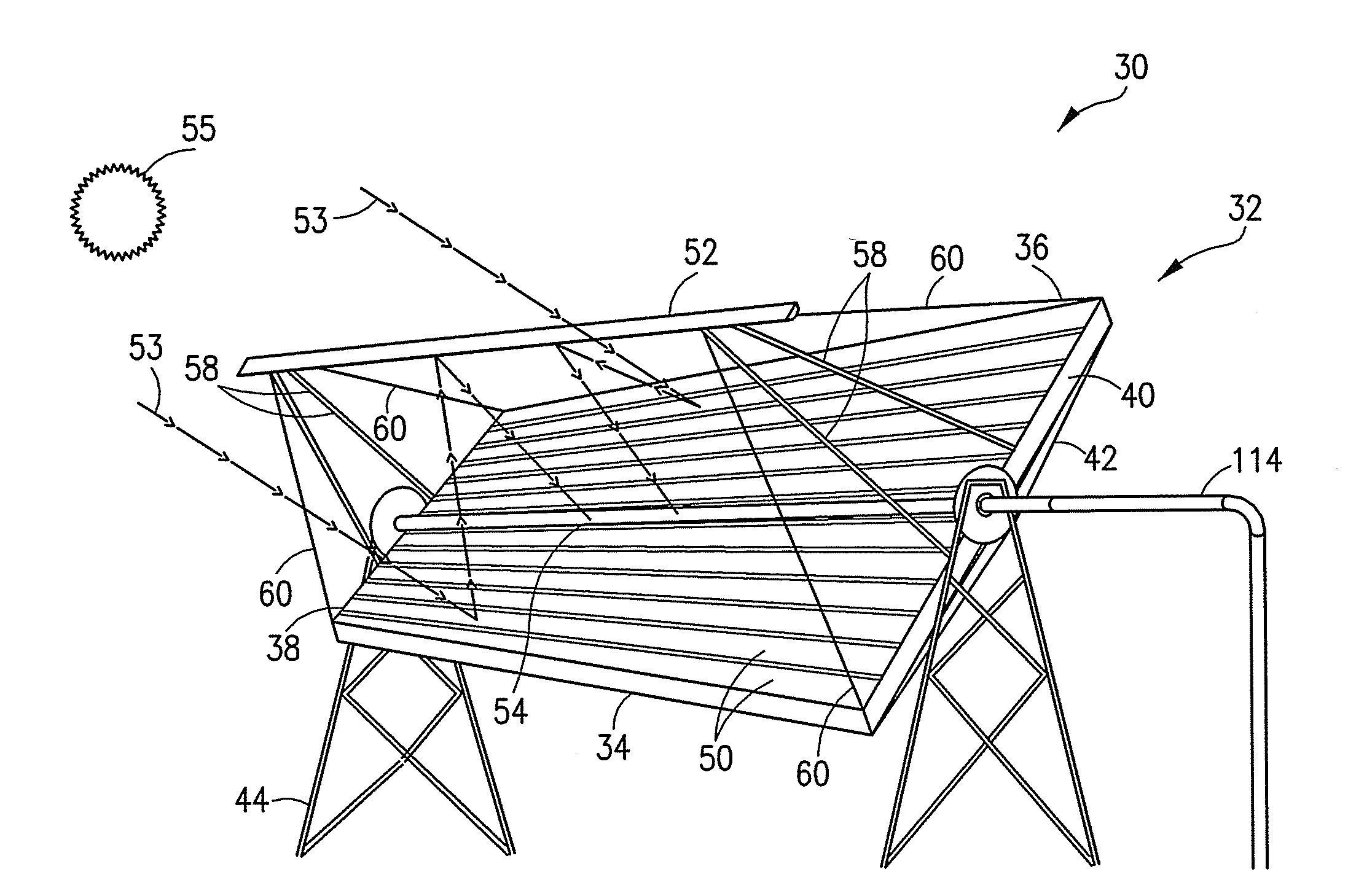

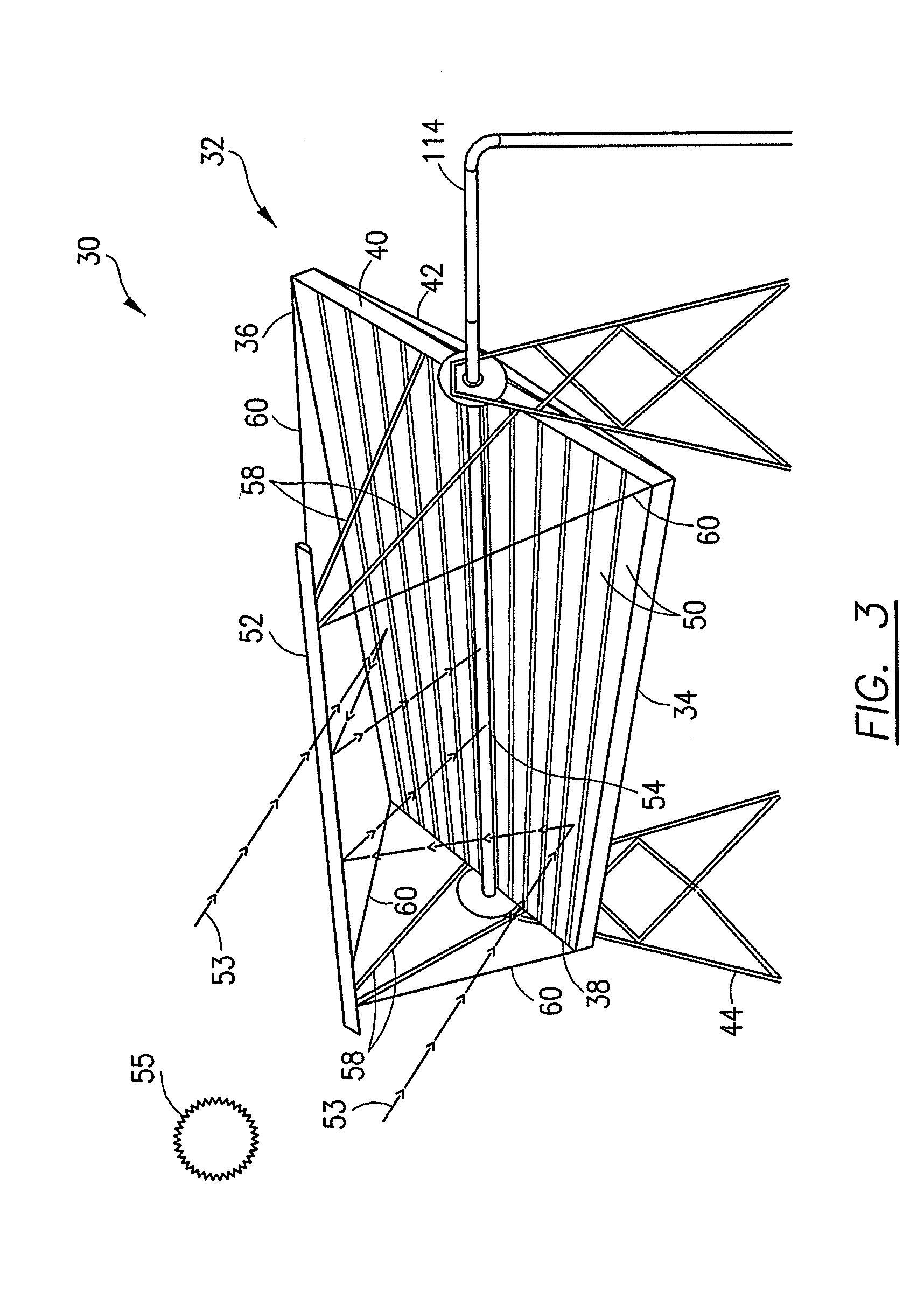

[0028]Referring now to FIGS. 3-12, one embodiment of a solar energy collection system according to this invention is illustrated which may comprise several individual reflector units 30 oriented side-by-side, as discussed below with reference to FIG. 12. The reflector unit 30 is initially generally described, followed by a discussion of individual aspects of the design.

[0029]The reflector unit 30 includes a frame 32 having opposed side walls 34, 36, and opposed end walls 38, 40 connected together in a generally rectangular shape as depicted in FIG. 3. The walls 34-40 are preferably formed of aluminum or other light-weight, weather resistant and durable material. The frame 32 is reinforced by a truss structure 42, a portion of which is shown in FIGS. 3 and 12, which is also preferably formed of aluminum or similar material. The truss structure 42 and frame 32 may be supported above ground level by pylons 44 secured on a foundation such as concrete footers (not shown) that can support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com