Mechanism for doubling soap dispensing amount of automatic soap dispenser

a technology of automatic soap dispenser and soap dispenser, which is applied in the field of automatic soap dispenser dispenser and soap dispenser mechanism, can solve the problem of not allowing the soap dispenser amount to return to a normal level, and achieve the effect of small resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

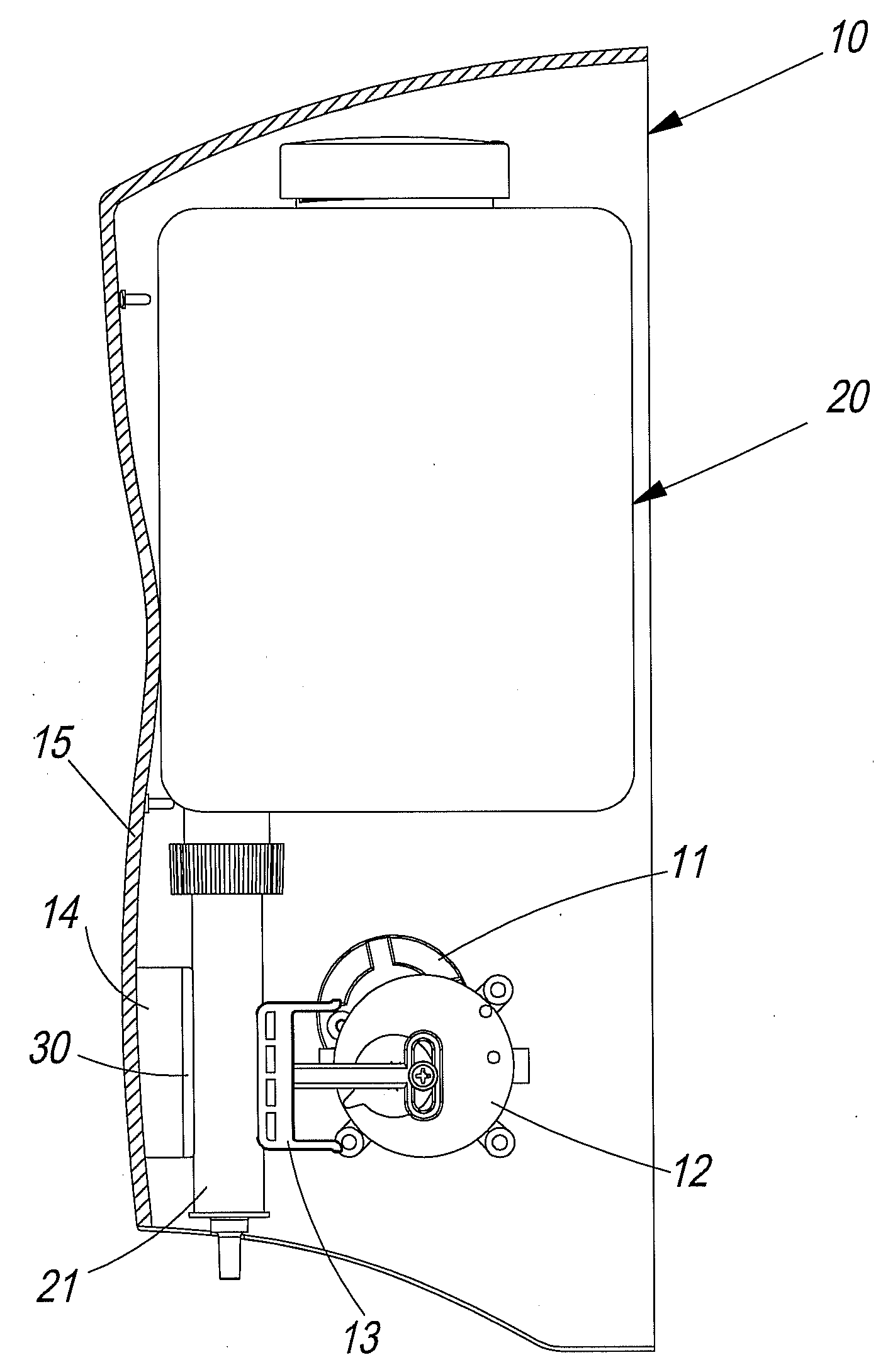

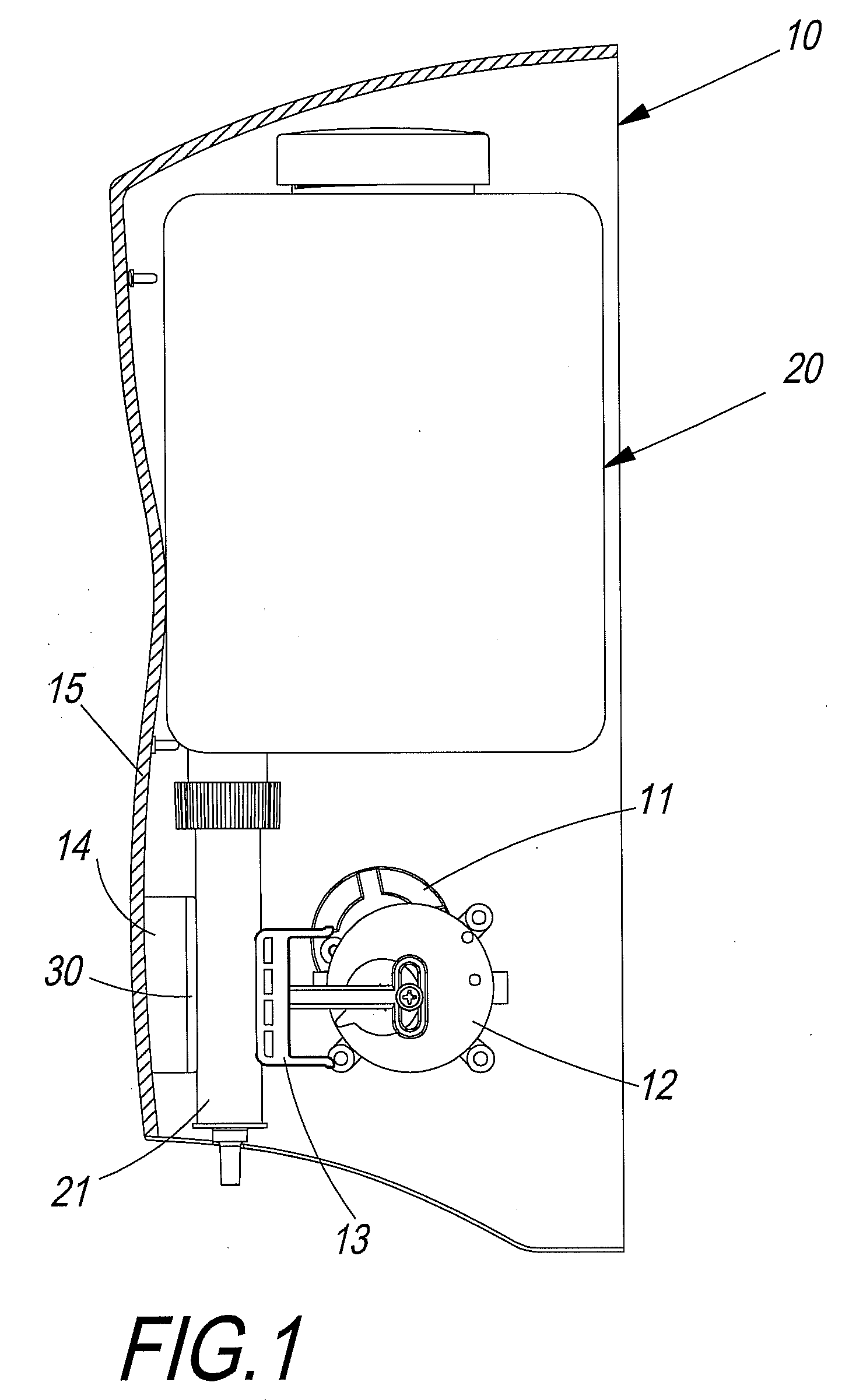

[0016]Referring to FIG. 1, according to a preferred embodiment of a mechanism for doubling a soap dispensing amount of a soap dispenser of the present invention, a soap dispenser 10 comprises a driving device disposed therein, wherein the driving device includes a motor 11 and a speed reducer 12 having an output end coupled with a pushing element 13. The mechanism further comprises a resisting element 14 provided on an inner surface of a casing 15 of the soap dispenser 10, wherein the inner surface is on a forward moving side of the pushing element 13; a soap container 20 having a bottom connected with a discharge tube 21 located between the pushing element 13 and the resisting element 14; and a pad 30, in the form of a plate or a block, coupled to a side of the resisting element 14 facing the pushing element 13 so as to be adjacent to an outer surface of the discharge tube 21.

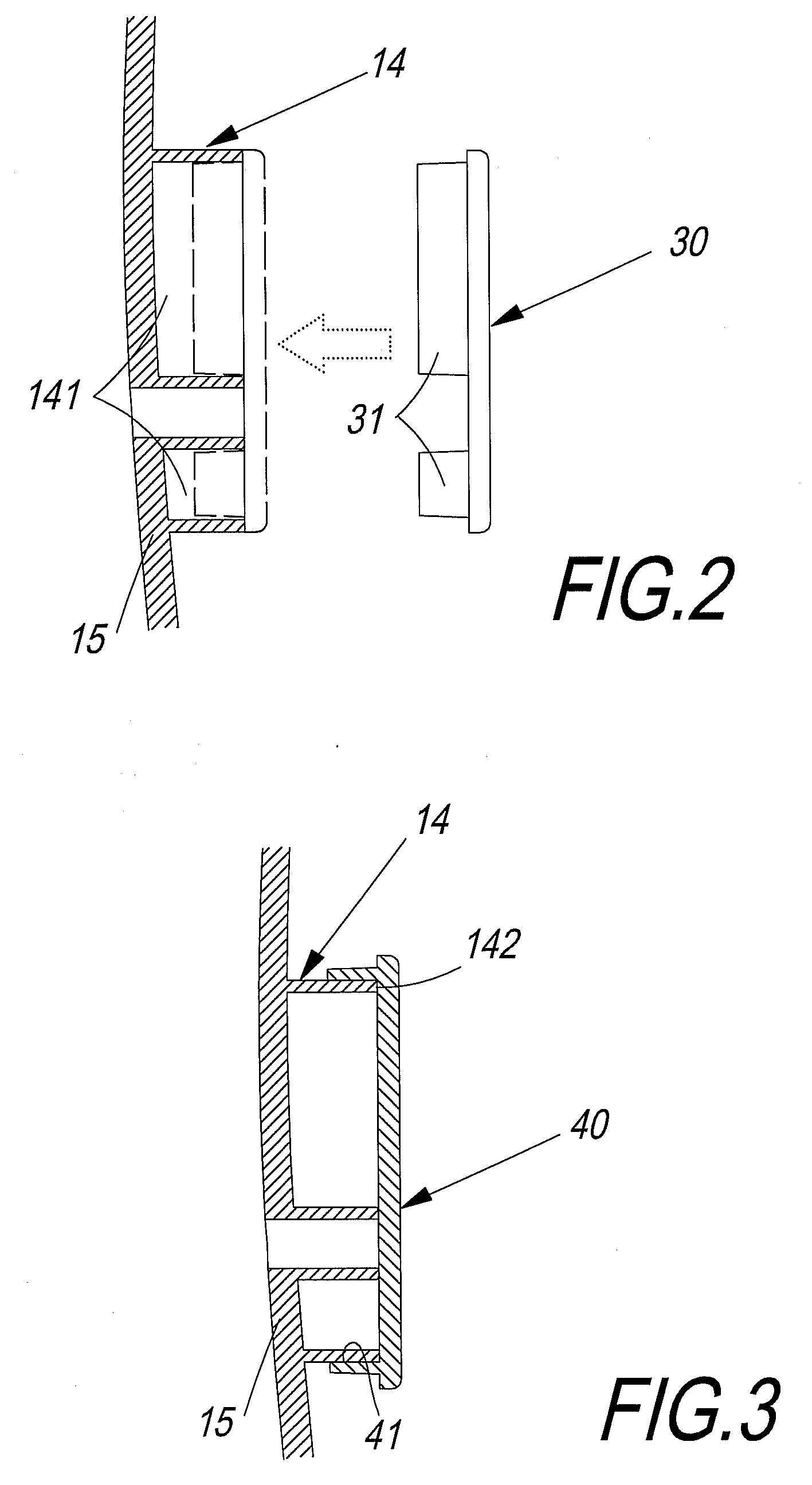

[0017]Referring to FIGS. 2 and 3, the pad 30 is preferably coupled to the resisting element 14 in a detacha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com