Chromatography Membranes, Devices Containing Them, and Methods of Use Thereof

a technology of chromatography membrane and ion exchanger, which is applied in the direction of cation exchanger, amphoteric ion exchanger, complex ion exchanger, etc., can solve the problems of significant downtime for a filter change, high-purity lysozyme recovery is extremely laborious and costly, and the filter is not fully plugged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Dead-End versus Cross-Flow Modes for Viral Capture

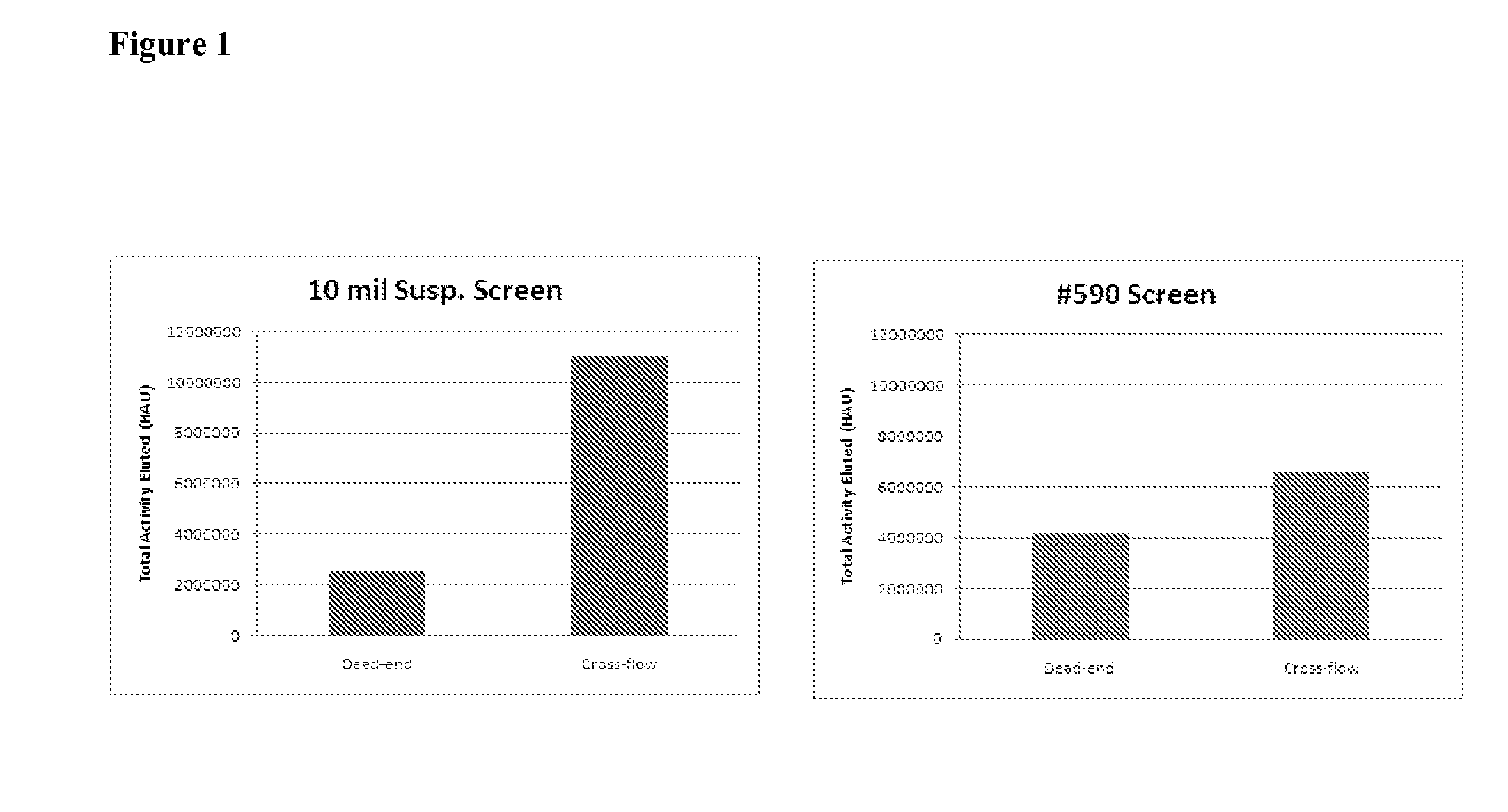

[0309]An example of the improvement of cross-flow technology versus dead-end technology can be realized when the two modes are compared directly to each other. FIG. 1 shows two experiments in which a specific device was run as a dead-end and as cross-flow device. The material of interest is a virus. In both cases, the capture of the cross-flow device exceeded the dead-end version, as indicated by the amount to the pure target material capture after washing and elution.

example 2

Chromatographic Capture and Harvest: Elution of Ovalbumin and Lysozyme

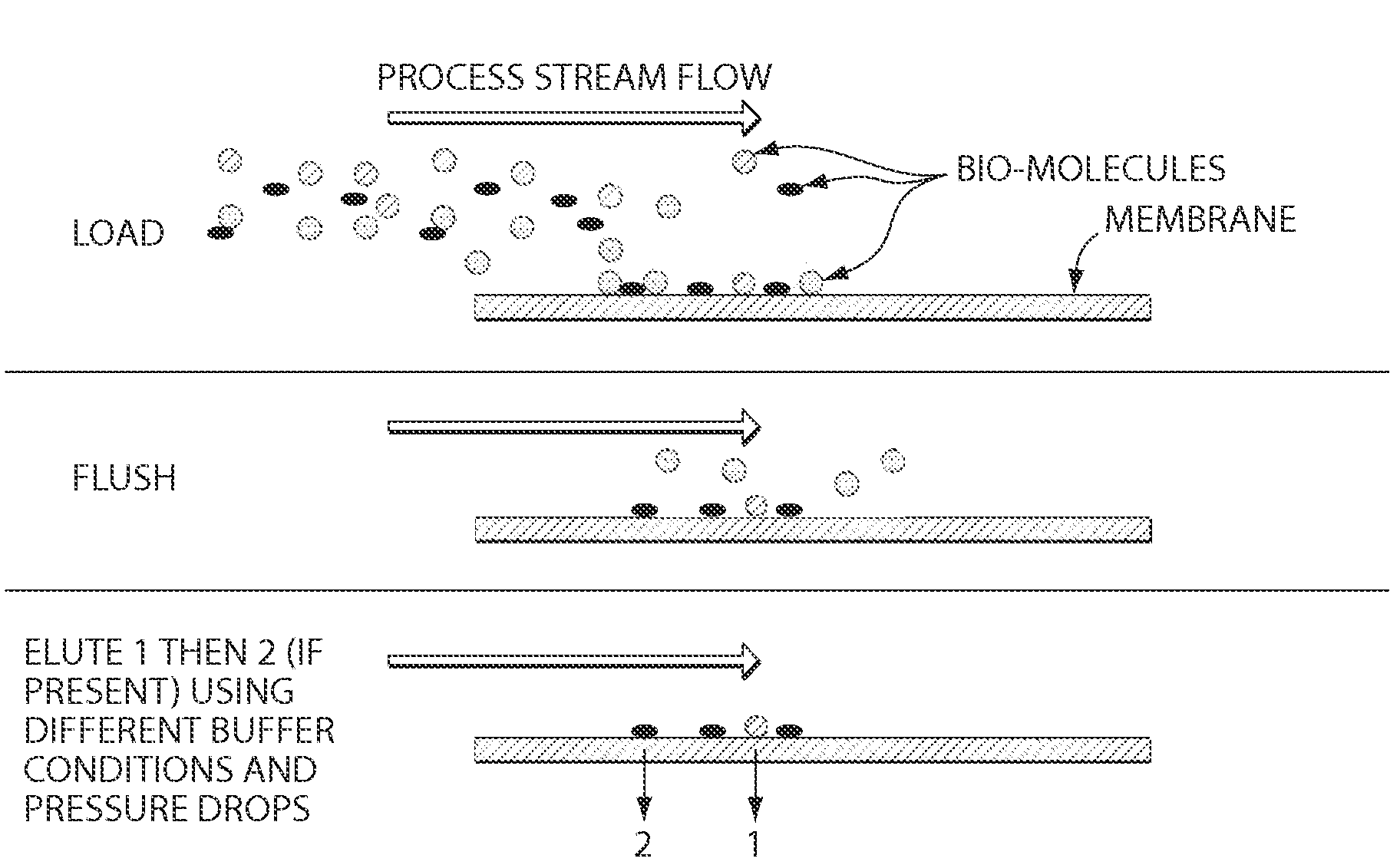

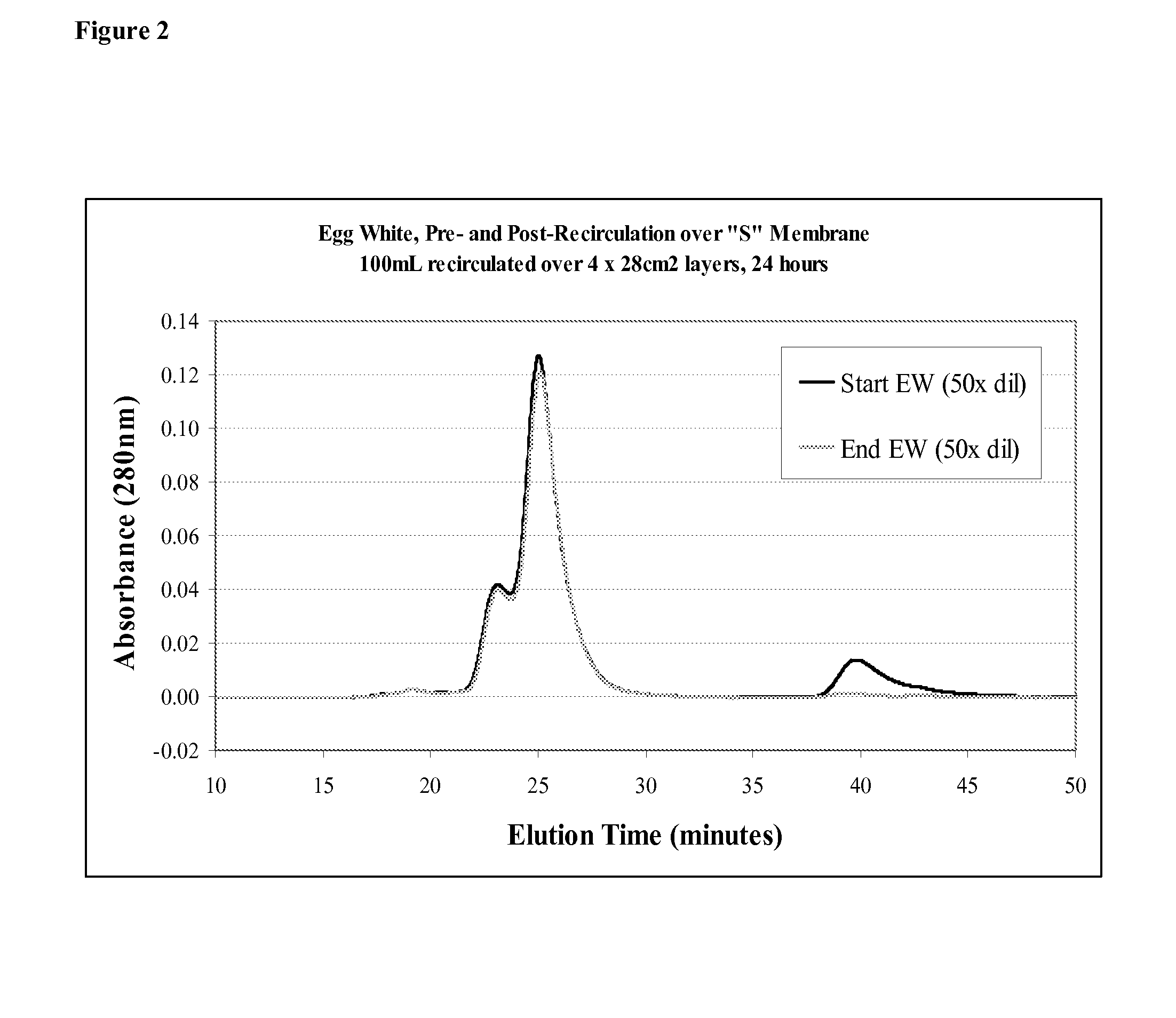

[0310]The membrane can selectively adsorb two protein materials from the feed stream and then, through the use of an altering buffer fluid, selectively elute the target bio-molecules. FIGS. 2 and 3 illustrate this effect. The initial feed stream of egg white was exposed to a membrane surface in cross-flow mode. Once the feed stream was removed and the membrane washed, both Ovalbumin and lysozyme were found adhered to the membrane (FIG. 2). Under specific buffer conditions, the proteins were selectively eluted (FIG. 3), which demonstrates the chromatographic nature of the membrane in cross-flow mode.

example 3

Orthogonal Two-Step Capture and Harvest

[0311]See FIG. 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com