Mechanical anastomosis system for hollow structures

a hollow structure and mechanical technology, applied in the field of hollow structure mechanical anastomosis system, can solve the problems of inability to make mechanical anastomosis, inability to achieve the effect of mechanical anastomosis, and a number of side effects of the heart-lung machine for the patient, so as to achieve the effect of convenient making of mechanical anastomosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

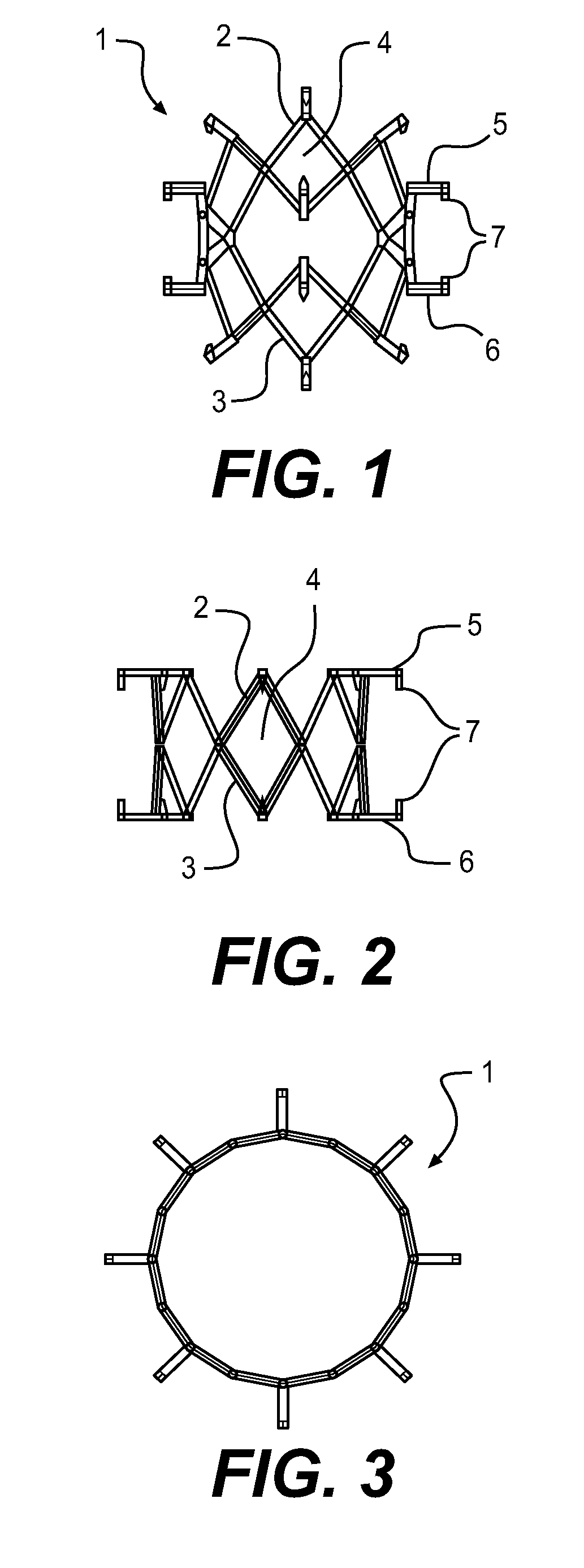

[0044]FIGS. 1-6 show a device for making anastomoses between hollow structures, in particular arteries or veins, by mechanical means.

[0045]In the present case, the device is a one-piece tubular or annular element 1, which is made of a biocompatible and plastically deformable material, for example a tantalum alloy or another material used in medical technology. Annular element 1 may be considered to be an assembly of two zigzag-like elongated elements 2 and 3 which extend substantially in circumferential direction but not along the contour line, which elements are interconnected at the facing vertices, thus forming a ring of diamond-shaped structures 4. Present on the vertices of the zigzag-like elements 2, 3 that face away from each other are pin-shaped elements 5, 6, which are provided with sharp tips 7 at their ends facing away from annular element 1, wherein the tips 7 of two associated pin-shaped elements 5, 6 forming a pair are directed towards each other. The pin-shaped elemen...

third embodiment

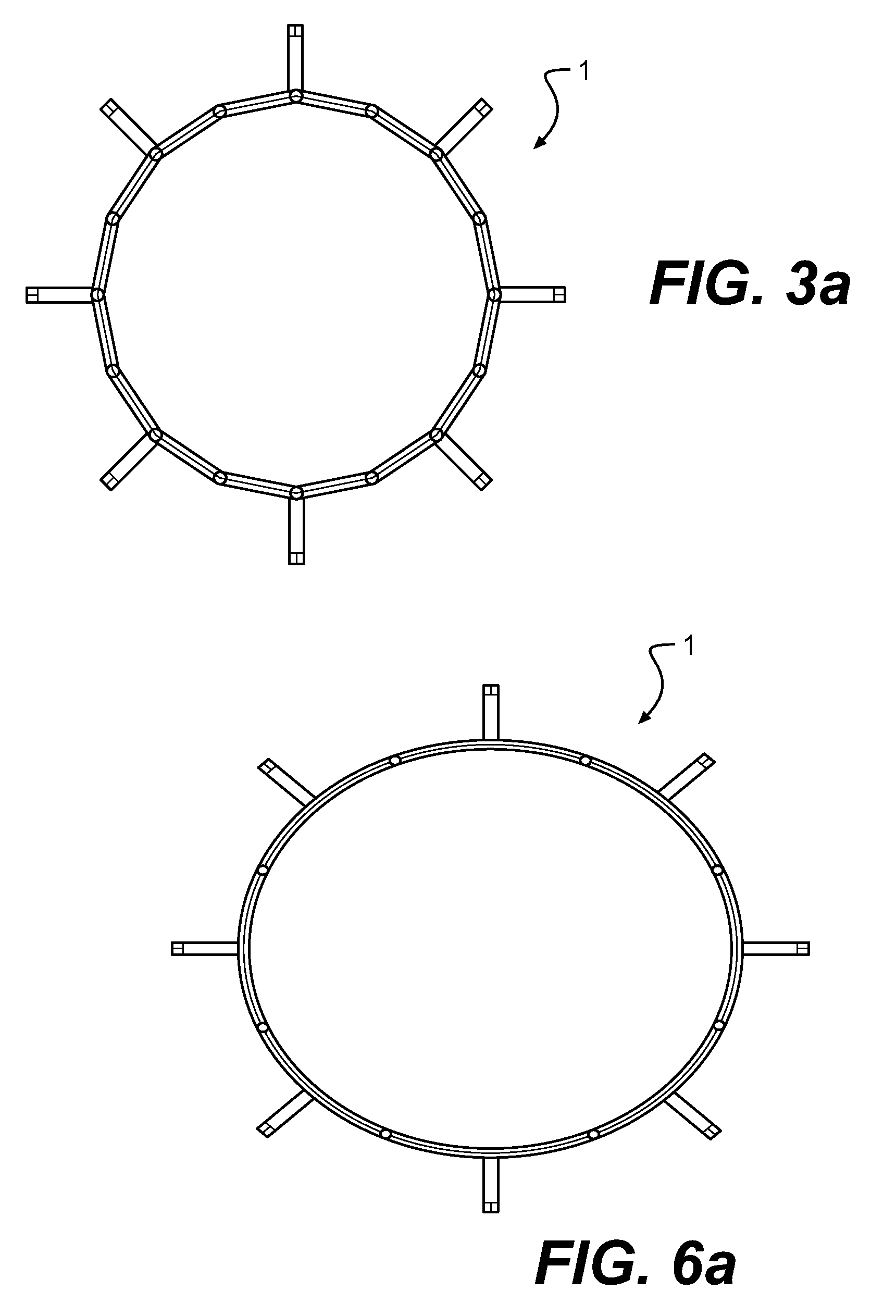

[0056]FIGS. 16-21 show the device according to the invention, which can be used for intraluminal placement in the case of a side-to-side anastomosis, but in particular also for extraluminal placement in the case of an end-to-side anastomosis.

[0057]In this case, annular element 1 consists of a circular, elongated element 19, which is circumferentially provided in a number of places with pin-shaped elements 20, which axially project to one side from said elongated element 19. The pins may be provided with points 21 thereby, whilst the pin-shaped elements 20 may be flat, or possibly round or the like. As is shown in FIGS. 19-21, the pin-shaped elements 20 are in large measure bent radially outwards in the joining position of the device, but they may also be bent tangentially.

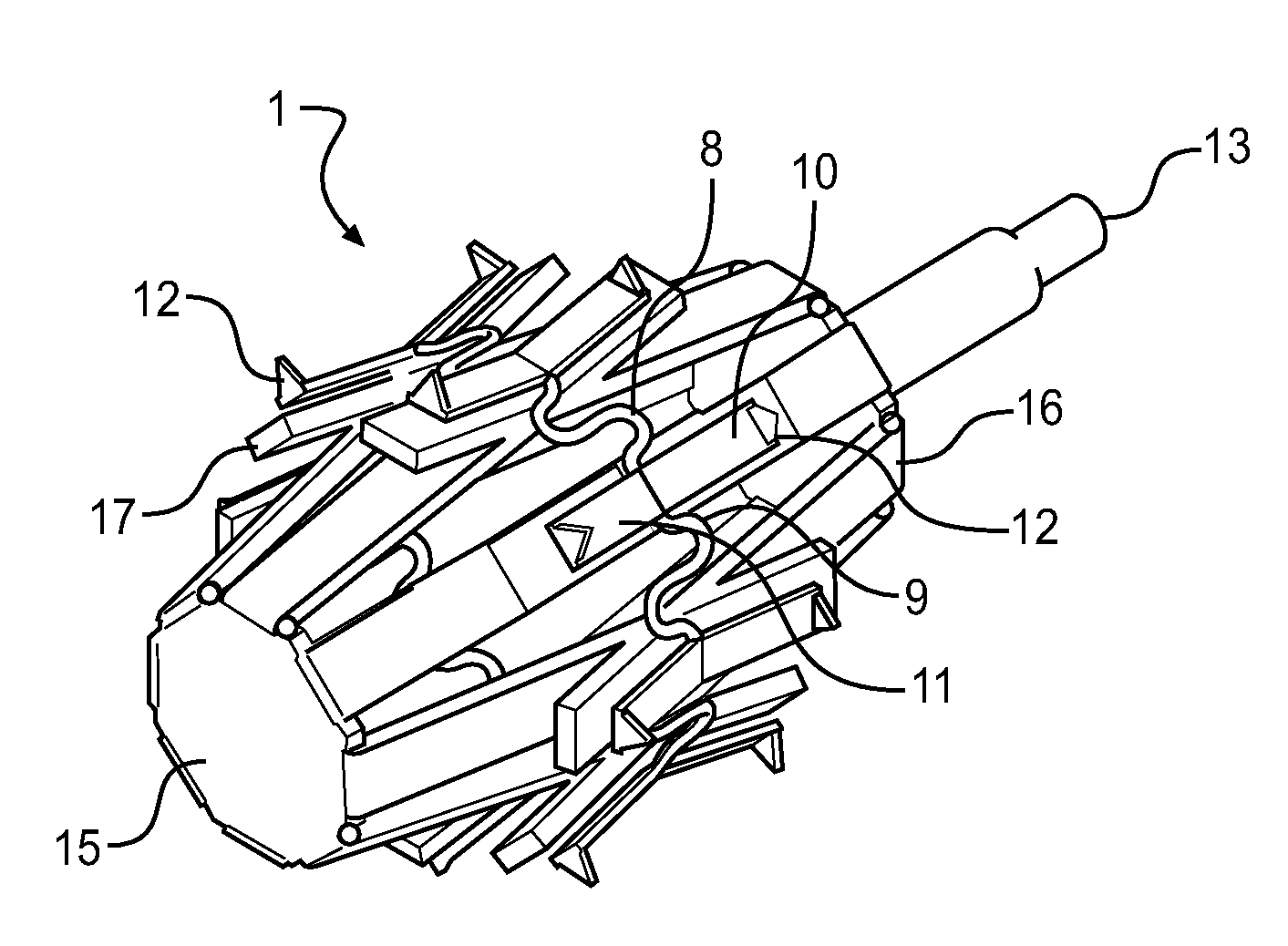

[0058]In order to be able to deform the pin-shaped elements 20 from the starting position to the joining position, the applicator according to FIGS. 22-24 is provided. Also this applicator is provided with a shank-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com