System and method for pump-controlled cylinder cushioning

a hydraulic actuator and pump-controlled technology, applied in the direction of fluid couplings, rotary clutches, servomotors, etc., can solve the problems of stroke, throttling flow through control valves, waste of energy,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

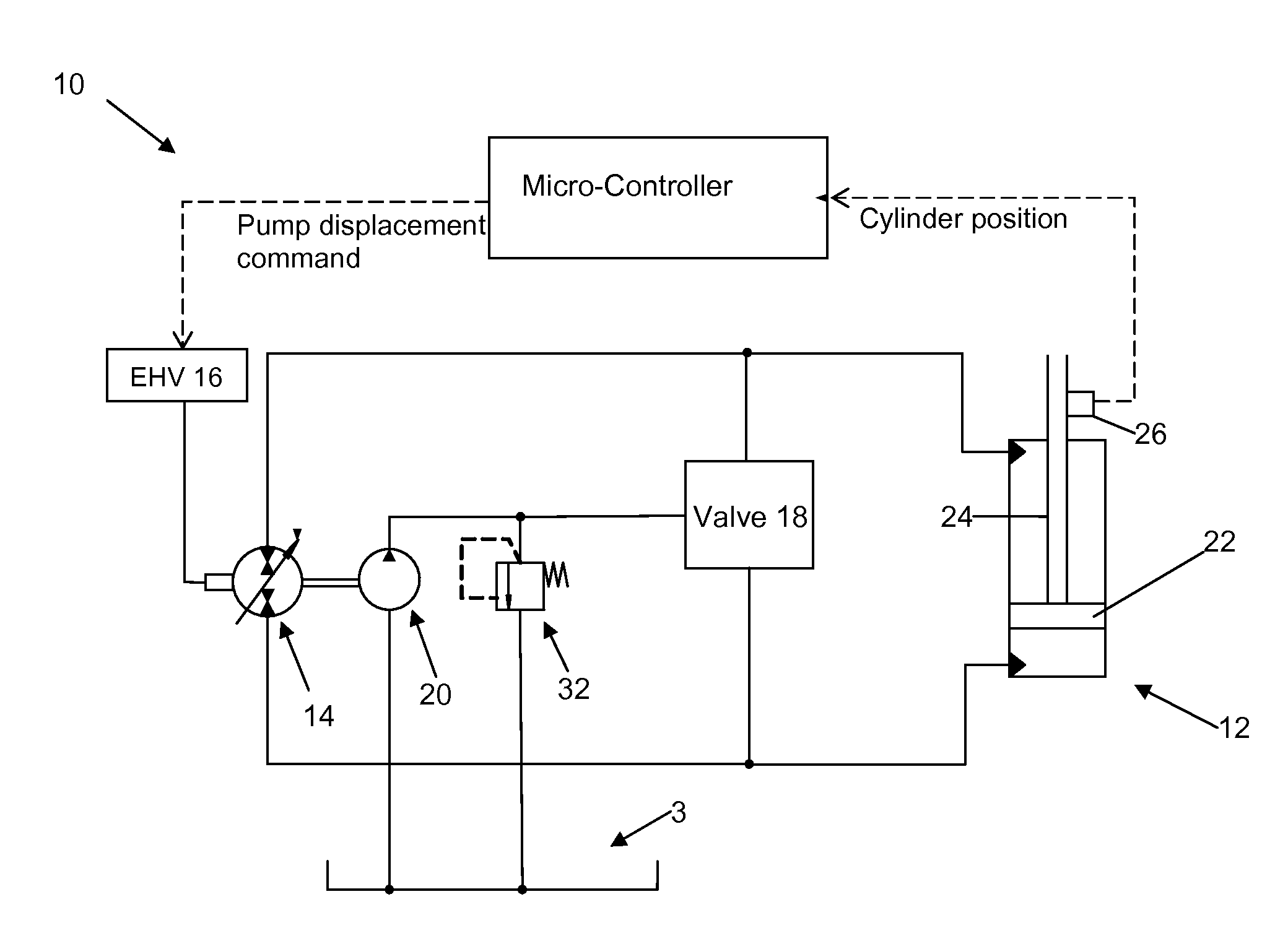

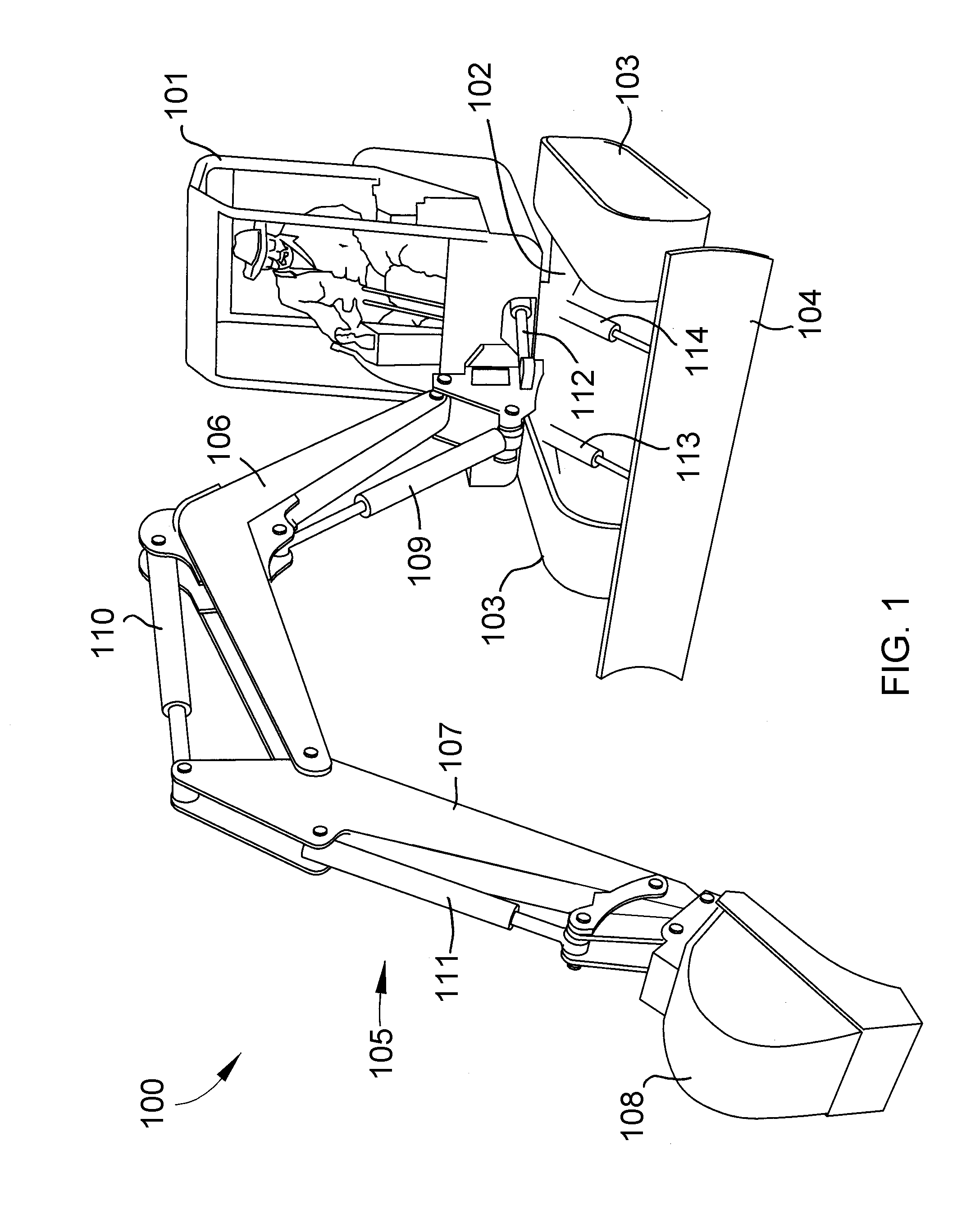

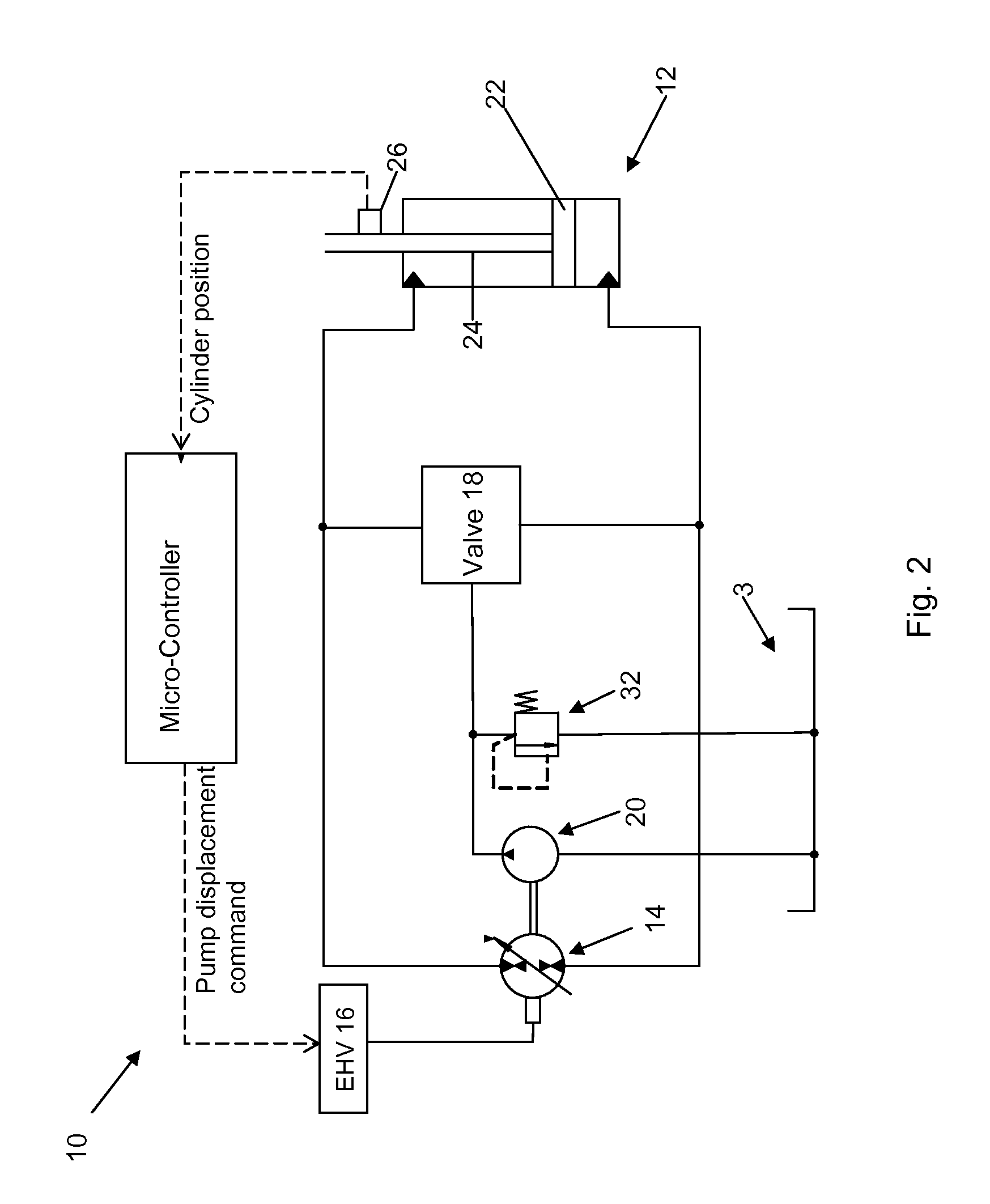

[0014]FIG. 2 schematically represents a system 10 for automatically controlling the position and velocity of a pump-controlled hydraulic actuator 12. The system 10 is represented in FIG. 2 as comprising a closed hydraulic circuit containing a pump-controlled hydraulic actuator 12 adapted to control the movement of an implement of an earthmoving machine, nonlimiting examples being any of the implements 104-108 of the excavator 100 of FIG. 1. As such, the actuator 12 can be exemplified by any of the linear actuators 109-114 of the excavator 100.

[0015]The system 10 of FIG. 2 further includes a variable displacement pump 14 connected to the hydraulic actuator 12, represented as a single-rod double-acting actuator. The pump 14 is powered by a primary power source (not shown), for example, an internal combustion engine. One or more valves 18 connect the hydraulic circuit to a suitable hydraulic fluid source, such as a charge pump 20 and reservoir 30 shown in FIG. 2, though the use of othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com