Prefabricated service pod

a service pod and prefabricated technology, applied in the direction of extraordinary structures, stairways, building components, etc., can solve the problems of compromising the suitability of particular purposes, difficult to alter the external appearance of finished buildings, and inefficient transportation of whole building units from the factory to the building site, so as to increase the cost of building contractors or property developers, cost efficient, and improve consumer desirability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

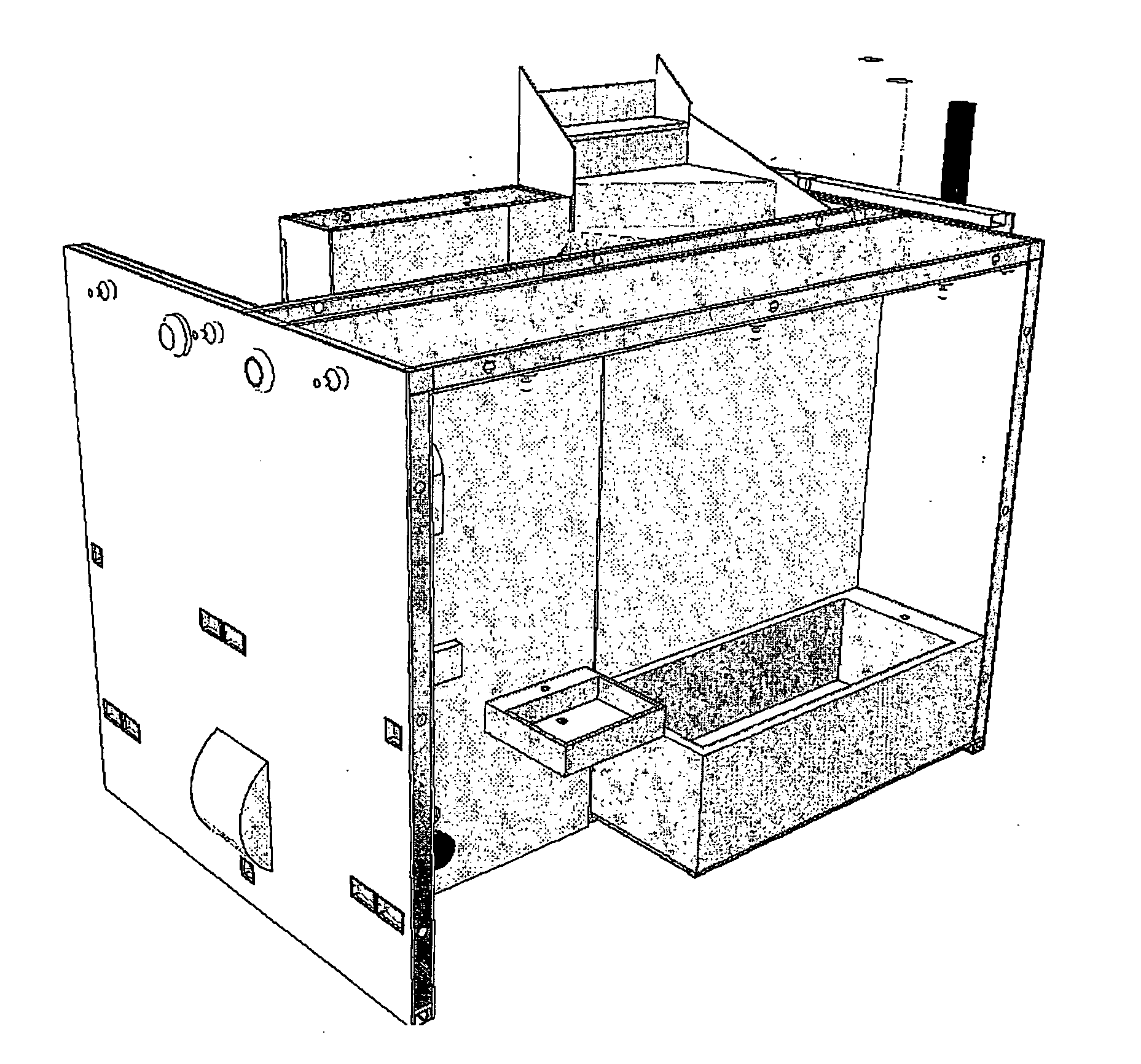

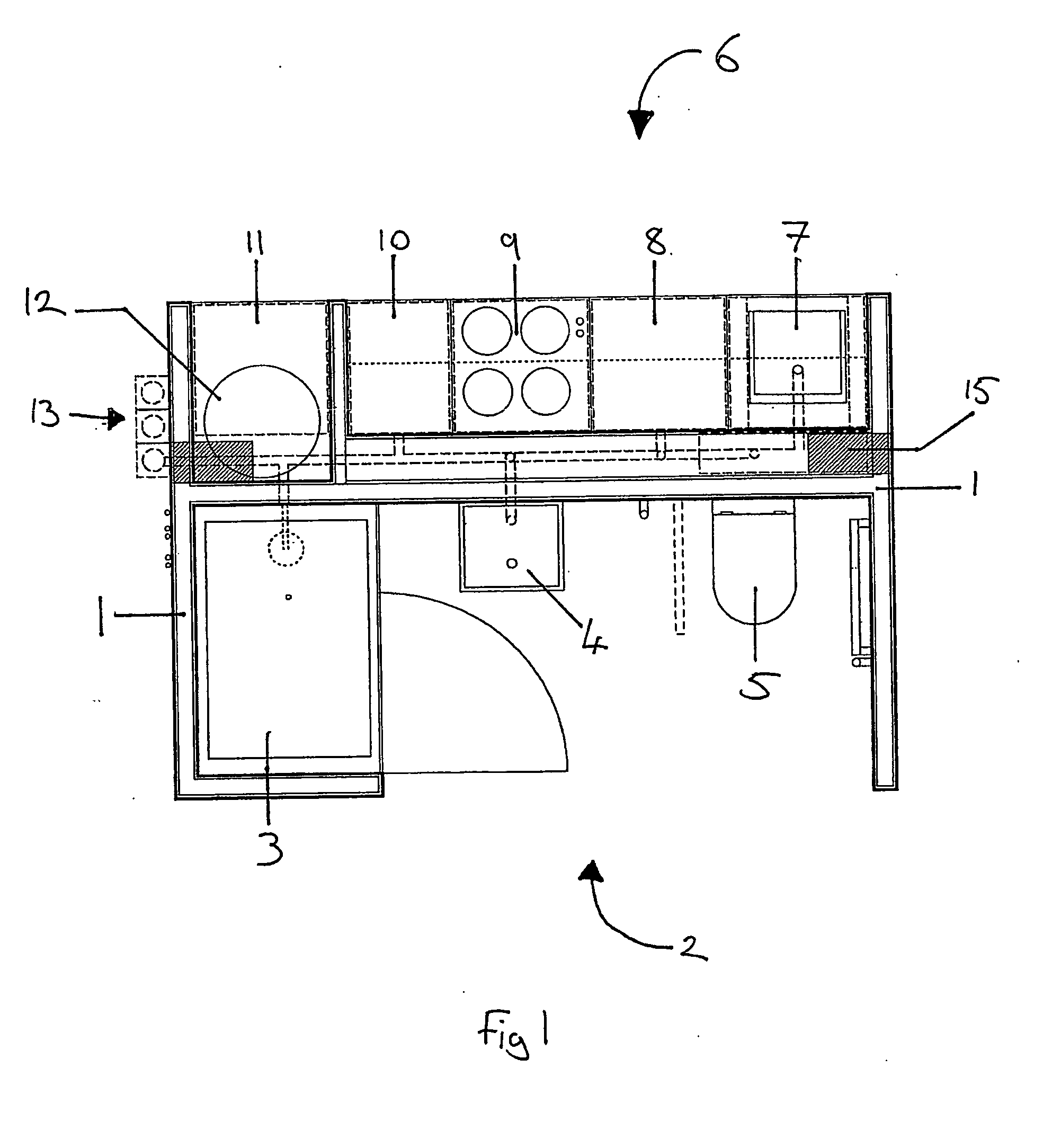

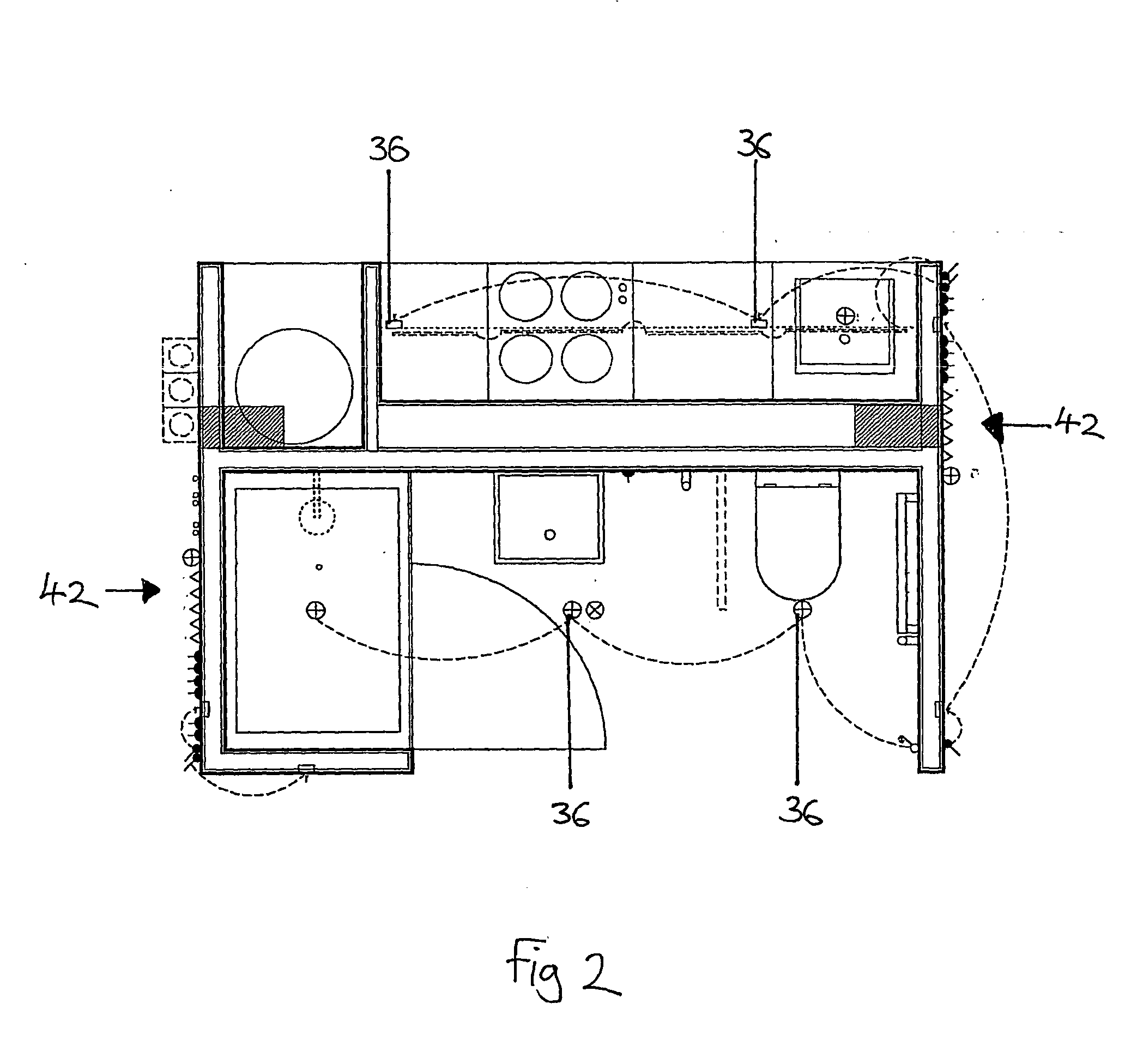

[0086]The plan view illustration of FIGS. 1 and 2 illustrate how the sections are attached around a frame work (1). To one side of the framework is a bathroom section (2) comprising a shower (3), a wash basin (4) and a toilet (5). To the other side of the framework (1) is a kitchen section (6). The kitchen section (6) comprises a sink (7), a washing machine (8), an oven and hob (9), a dishwasher (10), a refrigerator (11) and located in spaced relation above the refrigerator (11) is a hot water cylinder (12). Ventilation pipes (13) allocated to an unoccupied side of the framework, i.e. a side of the frame work to which neither the bathroom section nor kitchen section are attached and communicate with pipes running through a void within the framework (1). The pod illustrated also includes a macerator (14) and a heater (15). Cabling points (42) can be provided to the two ends of the pod, these points can be used to provide numerous connectivity points such as television sockets, a elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com