Apparatus and method for mixing, agitating and transporting molten or semi-solid metal-matrix composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

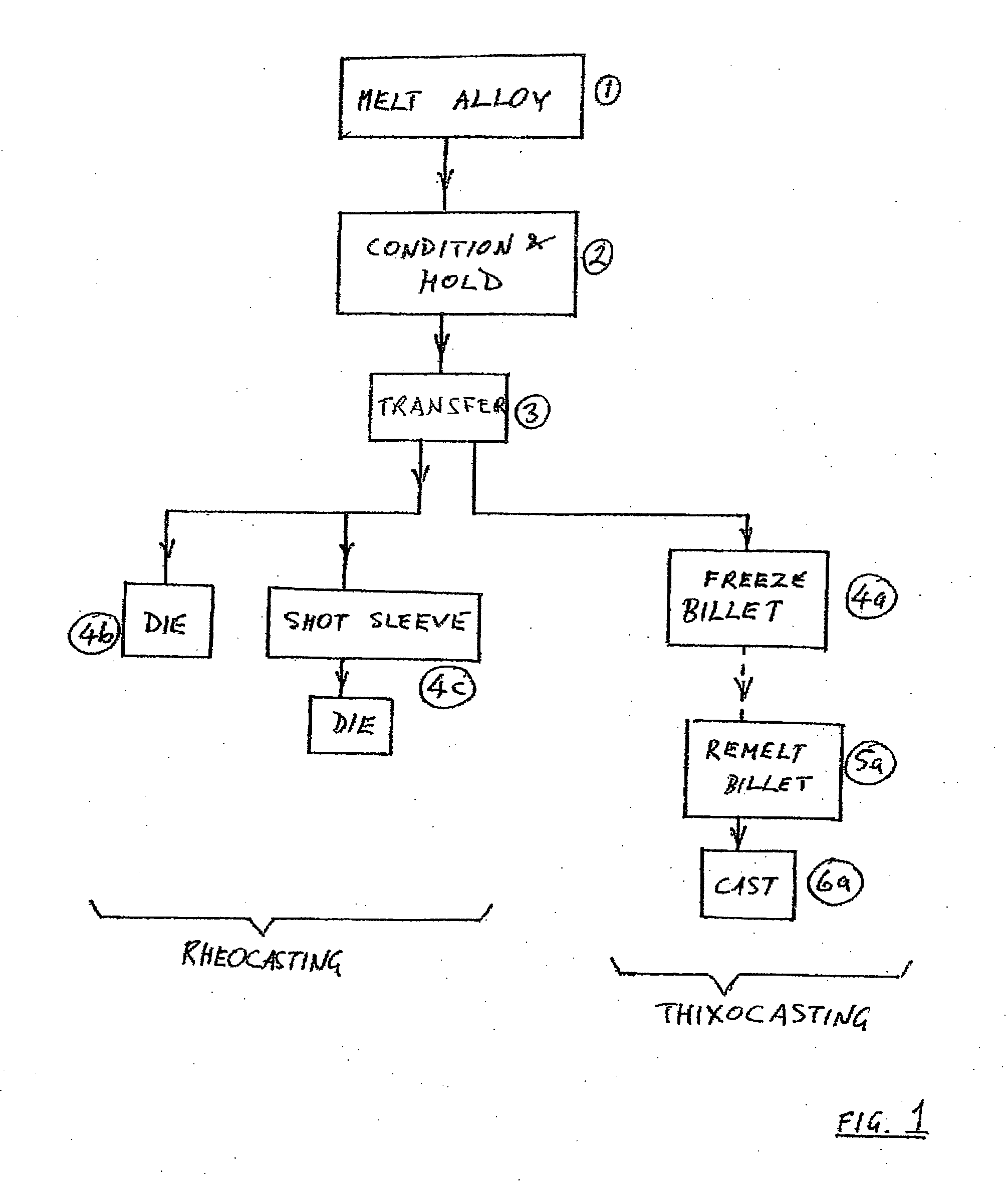

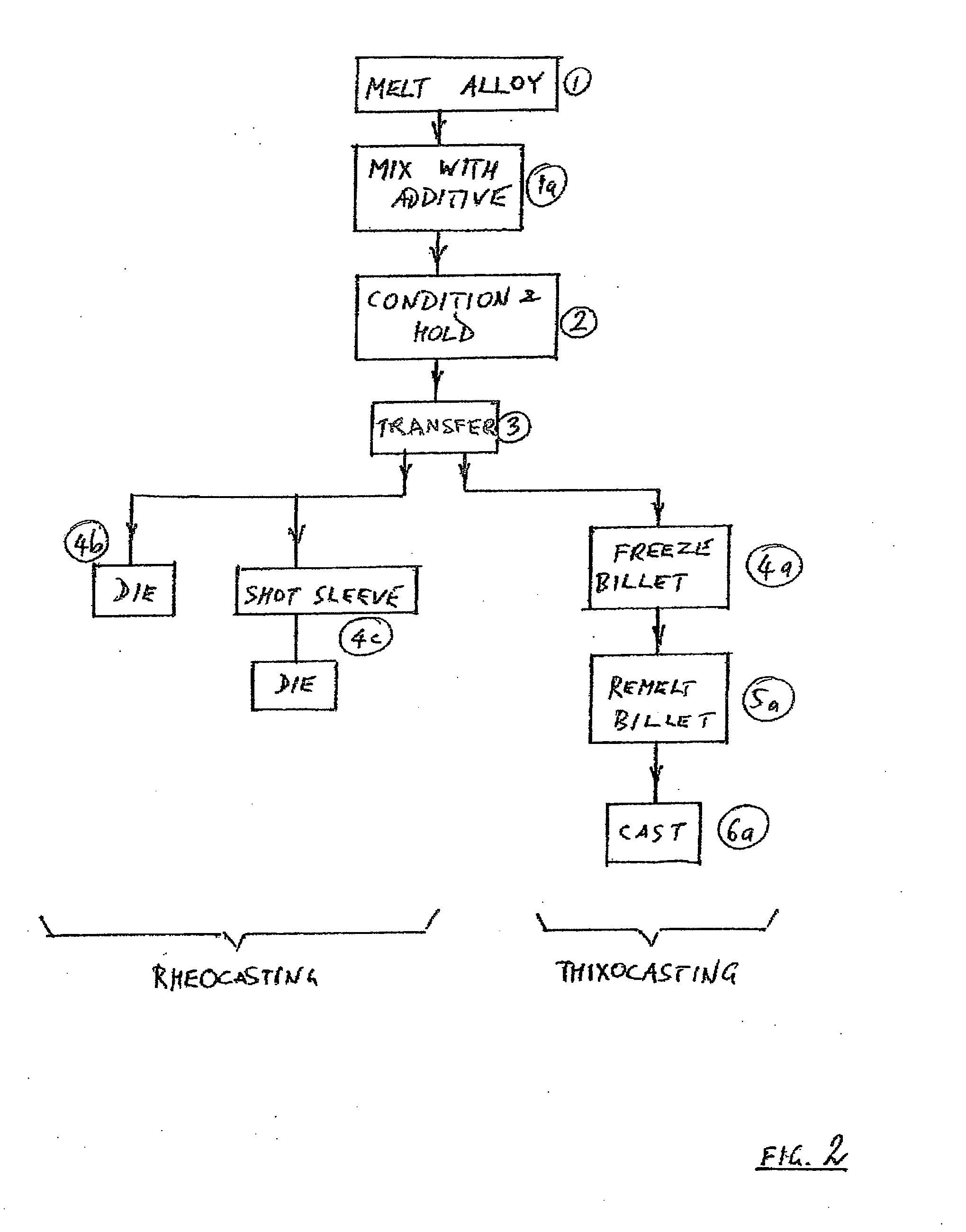

[0047]FIGS. 1 and 2 are process flow charts illustrating potential applications for the invention disclosed herein. FIG. 1 shows steps in the processes known as “thixocasting” and “rheocasting”, as described and distinguished from each other in, for example, U.S. Pat. No. 6,432,160, which is incorporated here by reference. In each of these processes, a metal alloy is first melted in known manner (Step 1), often under a controlled atmosphere. At this point, the alloy liquid is at a temperature above its liquidus temperature.

[0048]In step 2 (“condition and hold”), the melt is cooled below its liquidus temperature and above its solidus temperature and vigorously agitated. Due to cooling, dendritic solid particles begin to nucleate and grow. In the absence of sufficient agitation of the melt, these would progressively link, with the mixture progressively increasing in viscosity and in due course solidifying. The effect of agitation is to modify the microstructure of the solidifying all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com