Modular implant system with fully porous coated sleeve

a module and implant technology, applied in the field of prosthetic joints, can solve the problems of ligamentous instability, significant bone loss, failure of primary knee prostheses, etc., and achieve the effect of greater flexibility in the selection of implant components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

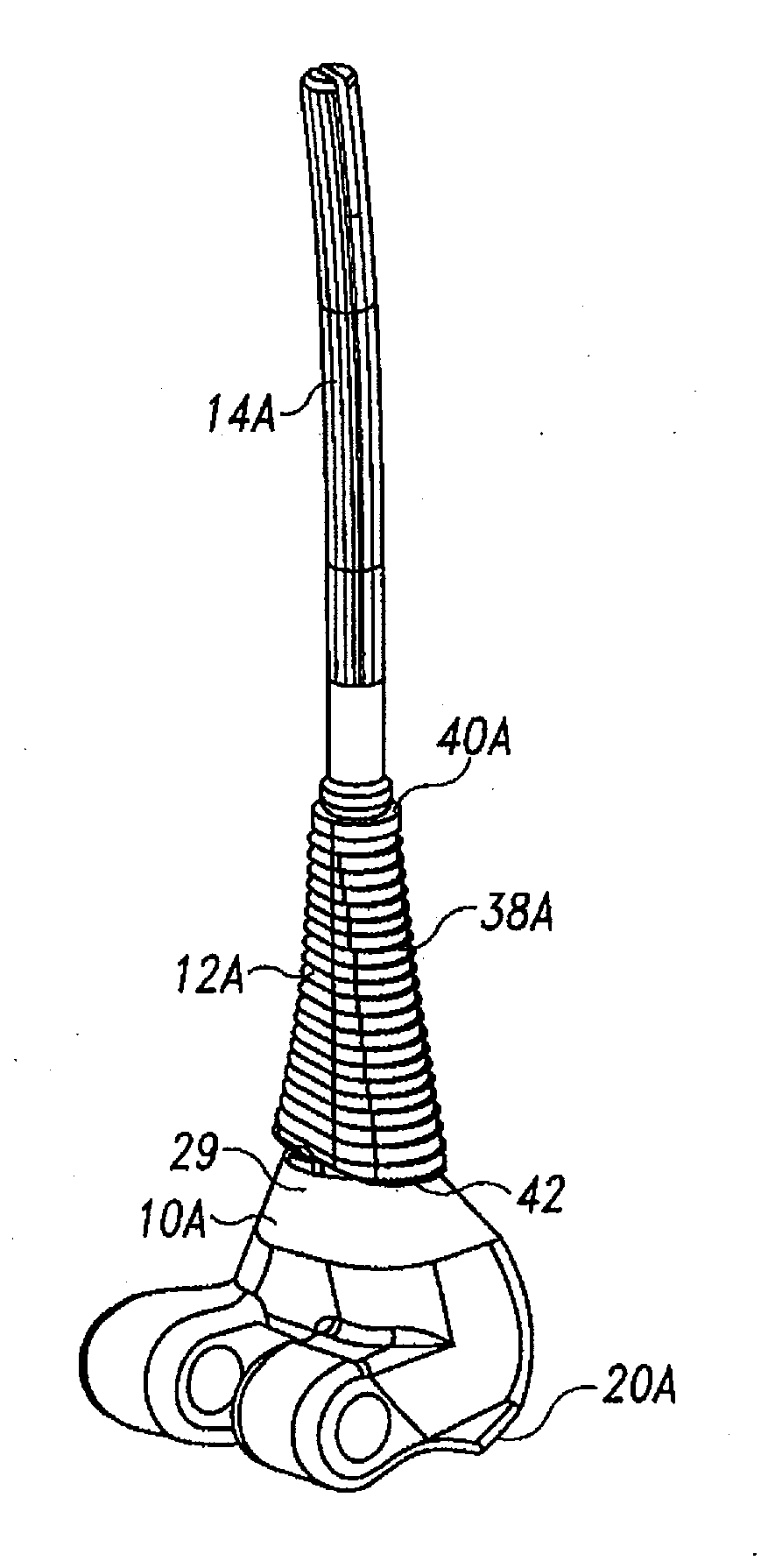

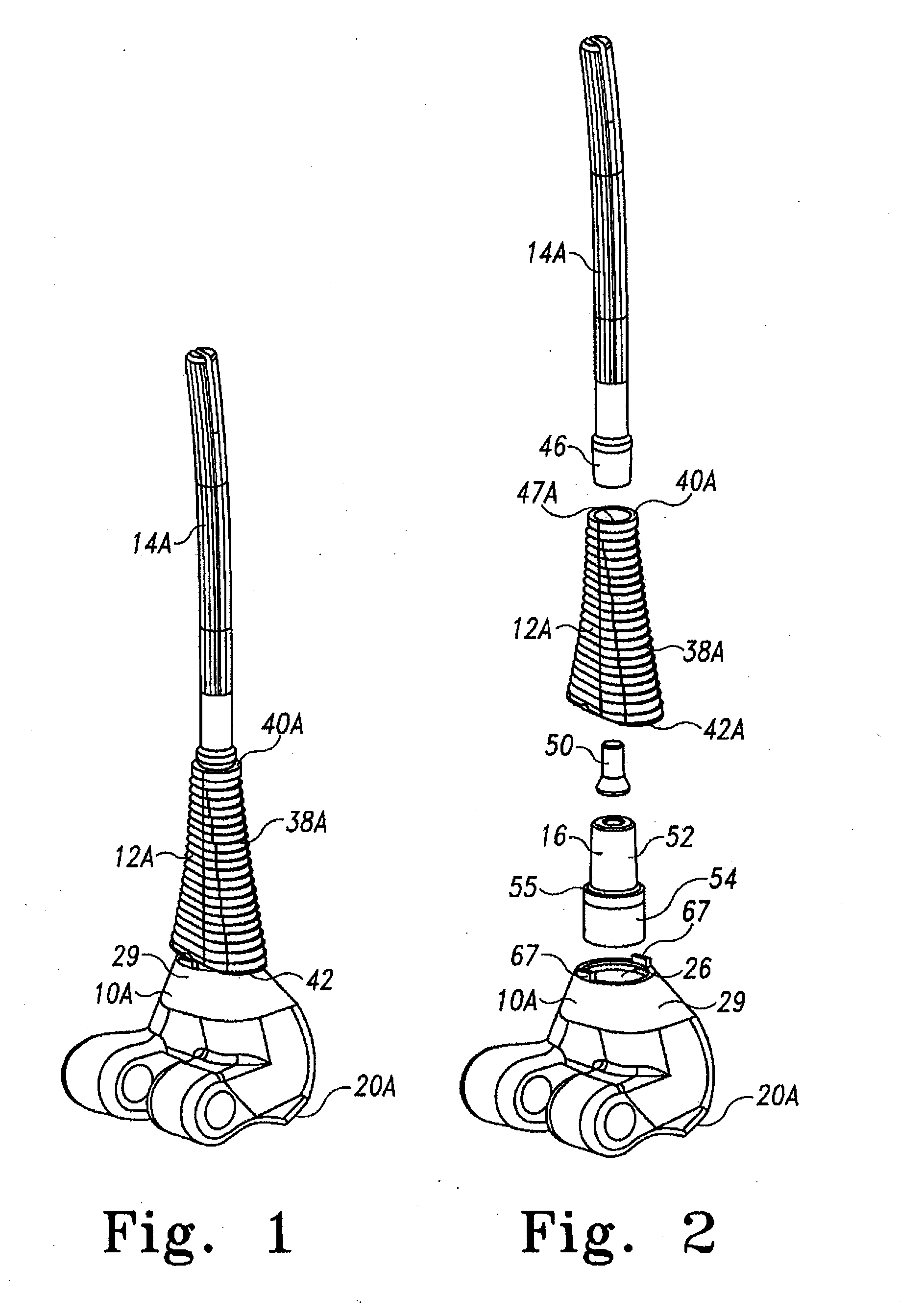

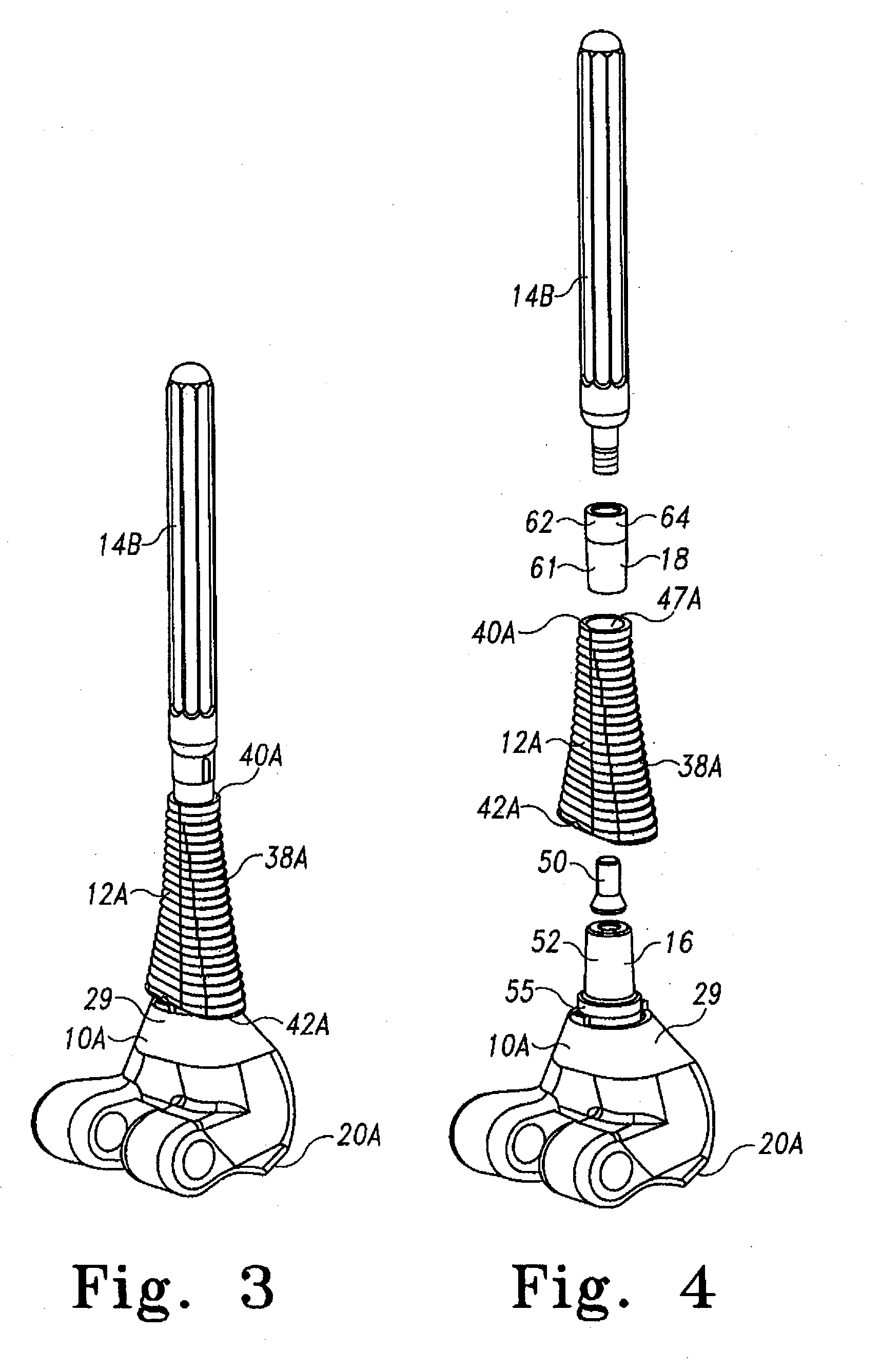

[0060]A modular orthopaedic knee implant system incorporating the principles of the present invention is illustrated in the accompanying drawings. The illustrated modular orthopaedic knee implant system includes components of several existing orthopaedic knee implant systems, along with new components that provide the orthopaedic surgeon with greater flexibility in selecting the appropriate components to suit the needs of an individual patient. These patient needs can include factors such as individual anatomy and the condition of the native bone tissue.

[0061]FIGS. 1-16 illustrate various combinations of knee implant components that can be achieved utilizing the principles of the present invention. The combinations illustrated in FIGS. 1-16 include four different styles of distal femoral components 10A, 10B, 10C, 10D, a new universal modular metaphyseal sleeve component 12A and two different styles of femoral stem extensions 14A, 14B. The illustrated combinations can be made through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com