Method for fabricating wick microstructures in heat pipes

a technology of wick and microstructure, which is applied in the direction of heat exchangers, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of increasing the difficulty of thermal management, shortened the use life of electronic components, and decreased clock speed and operation efficiency, so as to achieve the effect of easy understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

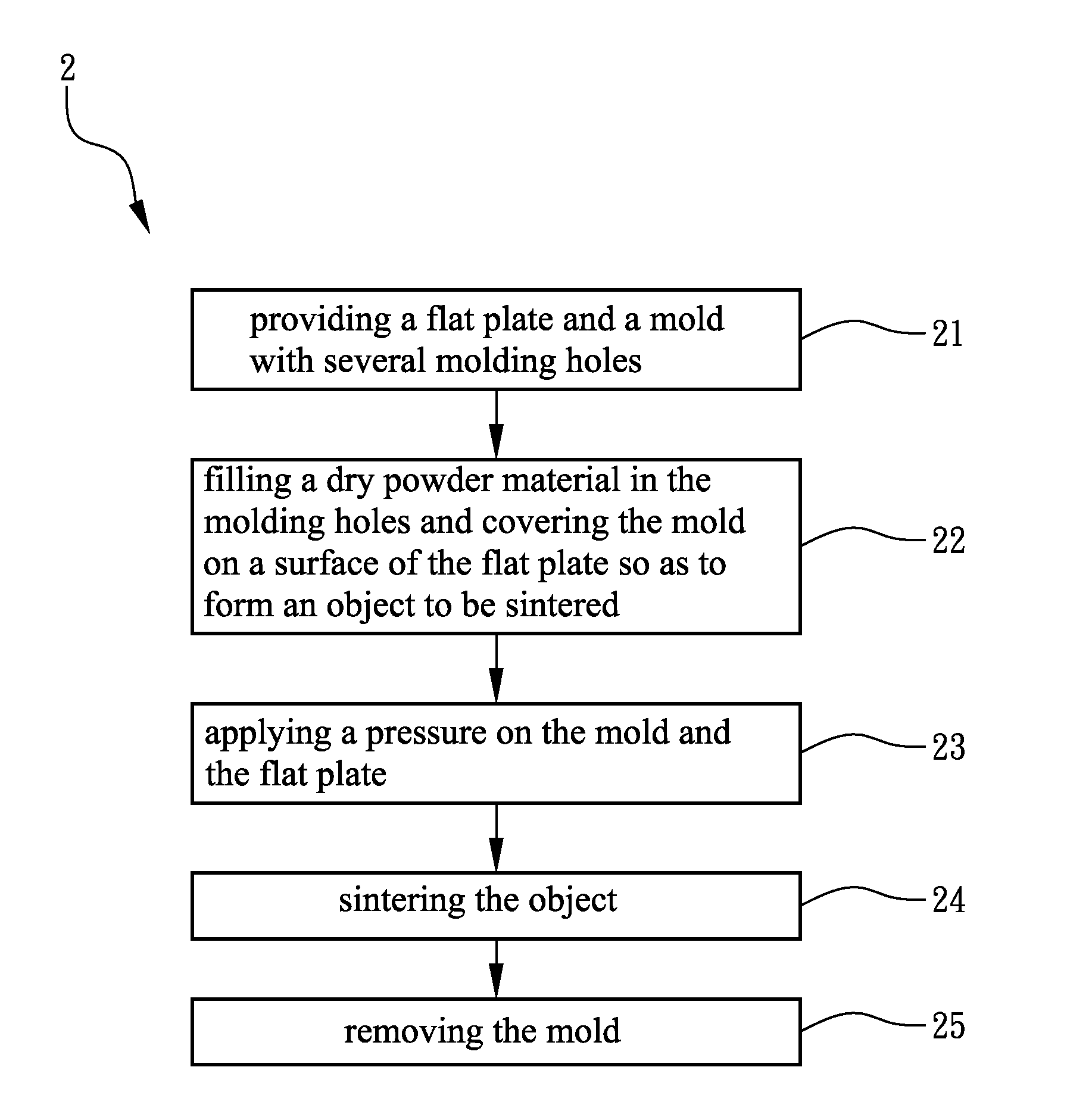

[0026]FIG. 1 is a diagram showing relations of heat transfer capability and tilting angle of various wick structures when depth of the wick structures is 1.0 mm. In FIG. 1, curve 81 represents a grooved wick microstructure sintered with powders having a diameter of 50 μm by the method of the present invention, curve 82 represents a grooved wick microstructure sintered with powders having a diameter of 100 μm by the method of the present invention, and curve 83 represents a grooved wick microstructure sintered with powders having a diameter of 200 μm by the method of the present invention. Curve 84 represents a simply sintered wick structure with no particular shape, which is merely sintered with a layer of powders, and curve 85 represents an ordinary grooved wick structure. It can be found in FIG. 1 that heat transferred by the wick structure of curve 84 when operated with a tilting angle will not be influenced much since this kind of wick structure has smaller apertures such that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com