Methods for detecting and measuring polysaccharide-hydrolyzing enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Modified Fast Assay for Corn Amylase

I. Enzyme Calibration Curve Construction Using % Admix.

[0071]1) Creation of Calibration Samples

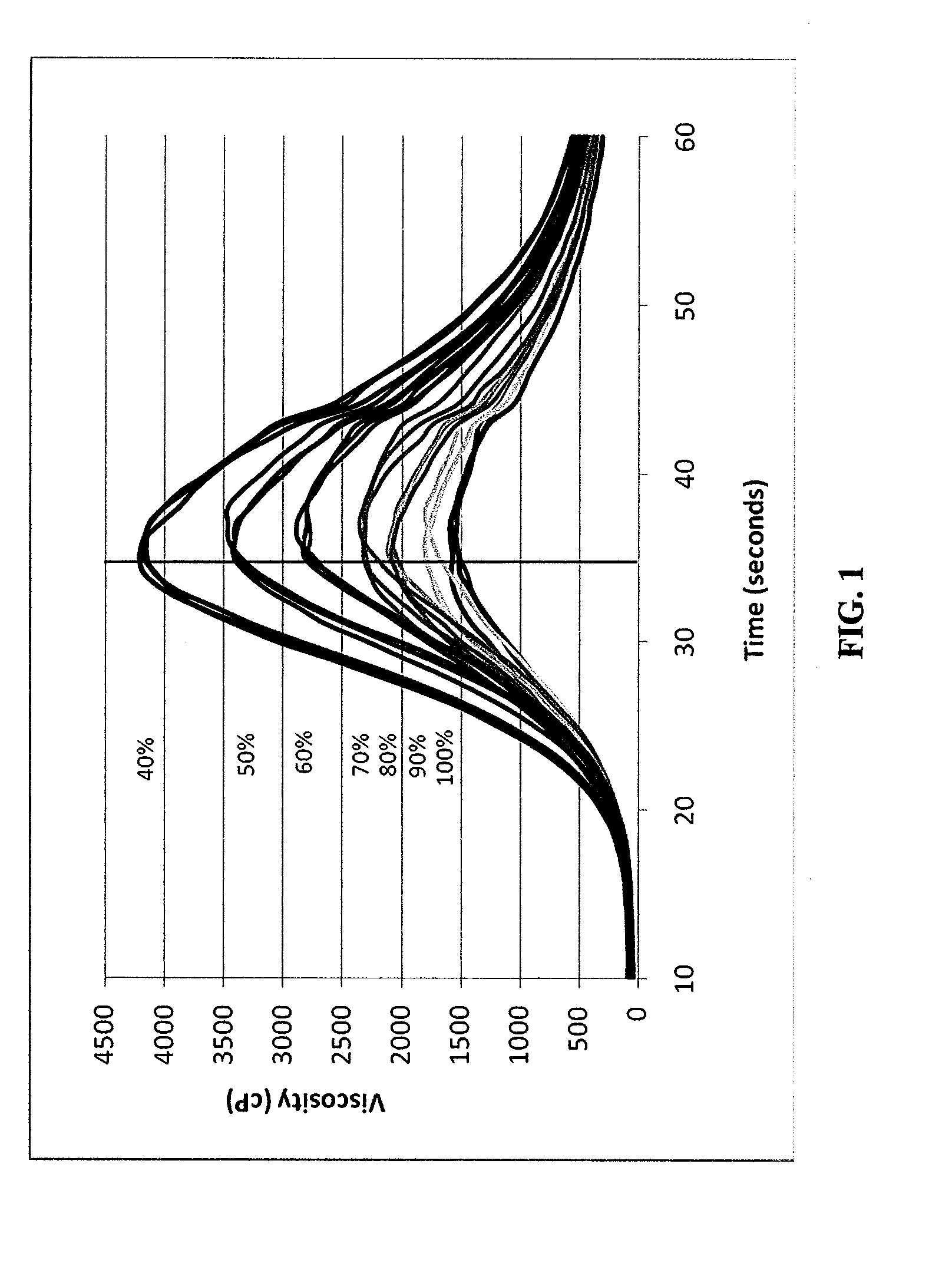

[0072]Corn Event 3272 (as described in U.S. 2006 / 0230473 comprising the thermotolerant alpha-amylase 797GL3) and commodity corn (negative background) (i.e. Yellow dent) was ground separately (i.e., dry milled) to flour in a Perten LM3600 Disc Mill (setting 0) (Perten Instruments AB; Huddinge, Sweden). Moisture content was measured using a Mettler Halogen Moisture Analyser to calculate total dry weight (data not shown). Admixtures of ground Event 3272 seed was mixed into ground commodity corn to make admixes of 40%, 50%, 60%, 70%, 80%, 90% and 100% using a calculated total dry weight of 500 g.

[0073]2) Viscosity Measurement

[0074]Approximately 9-20 grams of each admixture was weighed separately into viscometer vessels. Water was next added to each tube to create a slurry containing about 28% dry solids. Corn slurry has very good buffering capacity, so it is...

example 2

Modified Fast Assay for Corn Amylase Using a Standard Coffee Maker

[0091]1) Creation of Calibration Samples

[0092]Calibration samples were created essentially as described in (Example 1) above. Corn Event 3272 (comprising the thermotolerant alpha-amylase 797GL3) and commodity corn (negative background) (i.e. Yellow dent) were ground separately (i.e., dry milled) to flour in a Perten LM3600 Disc Mill (setting 0) (Perten Instruments AB; Huddinge, Sweden). Moisture content was measured using a Mettler Halogen Moisture Analyser to calculate total dry weight (data not shown). Admixtures of ground Event 3272 seed was mixed into ground commodity corn to make admixes of 40%, 50%, 60%, 70%, 80%, 90% and 100% using a calculated total dry weight of 500 g.

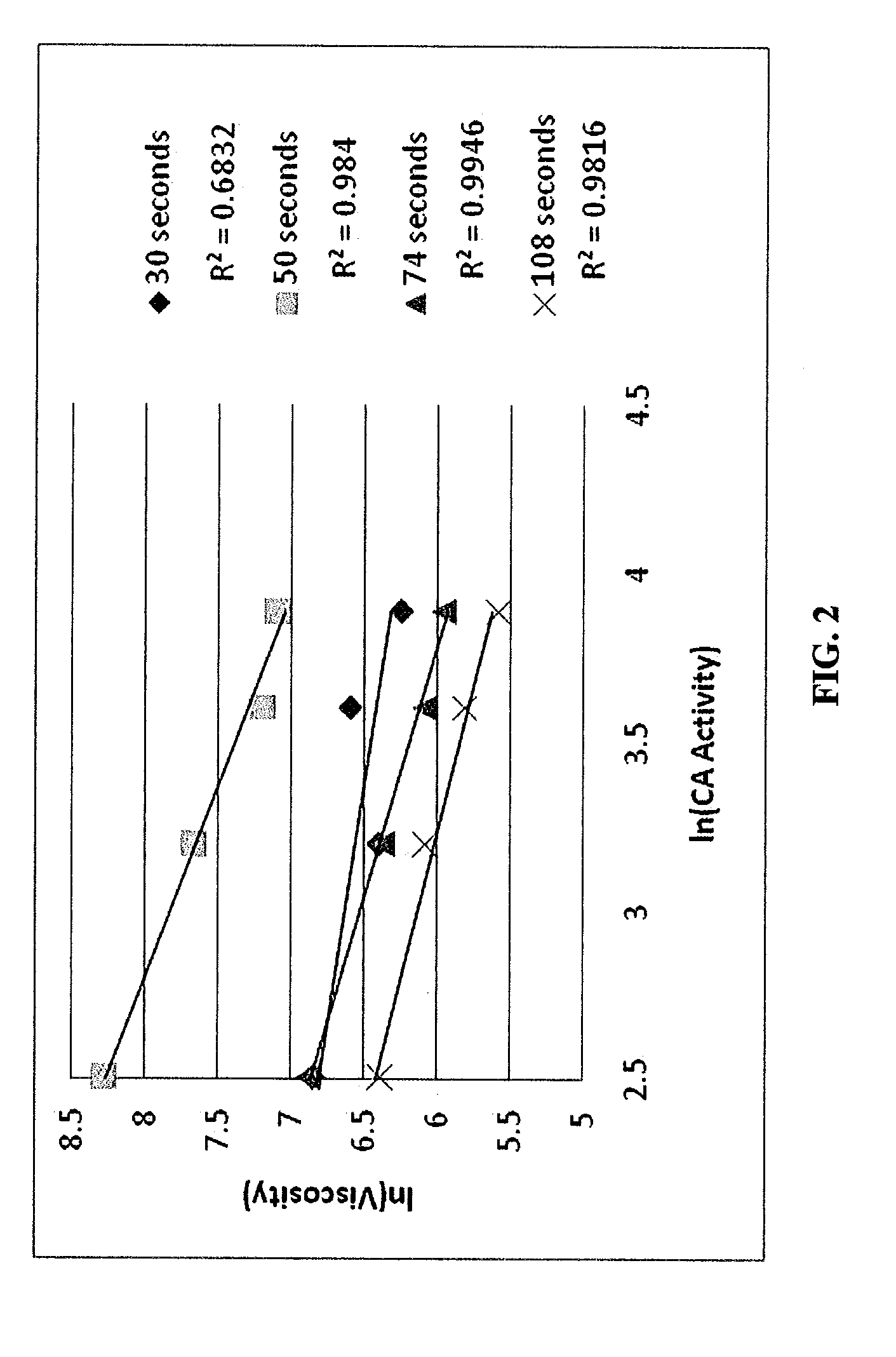

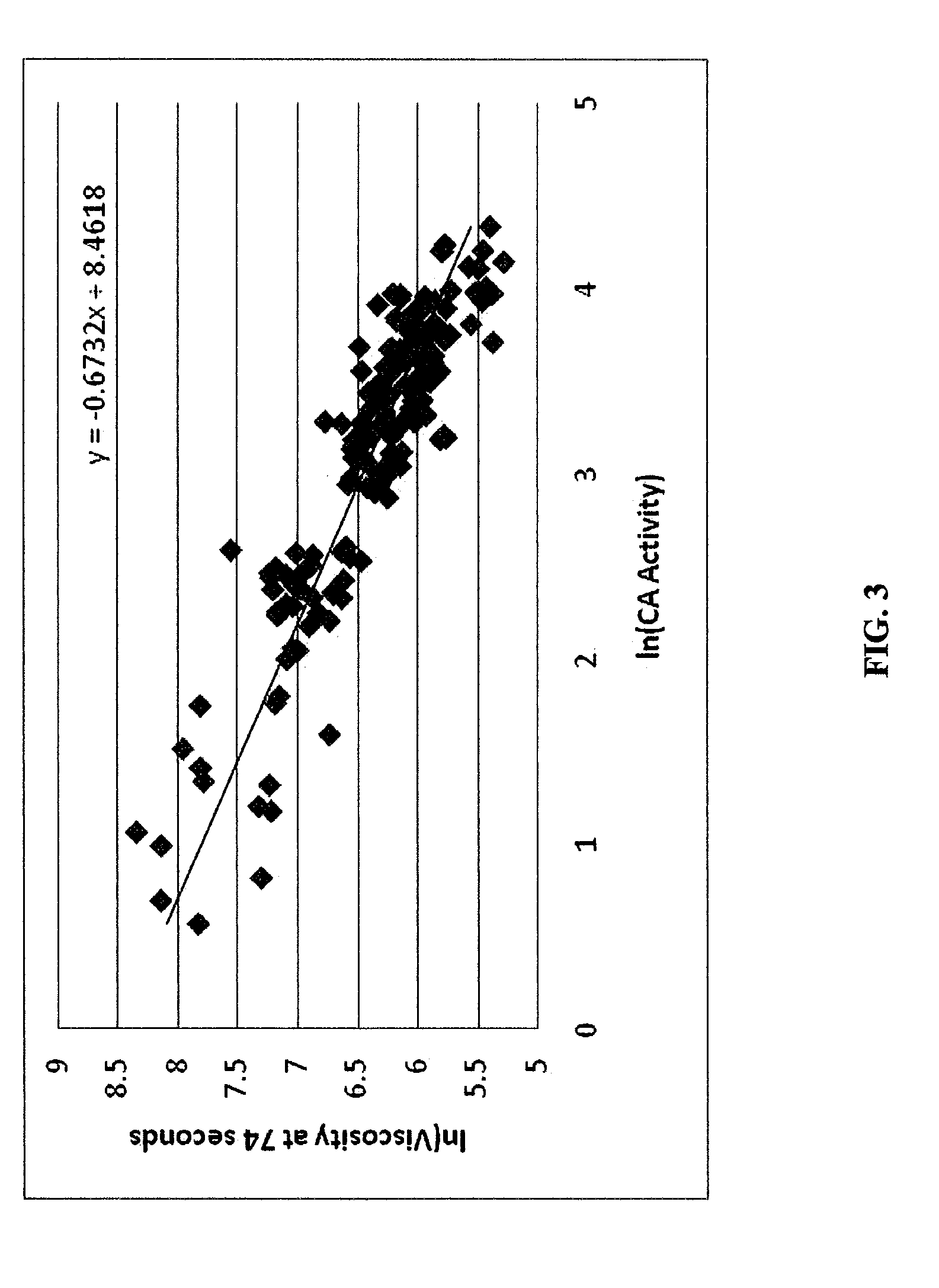

[0093]2) Generation of a Calibration Curve

[0094]Approximately 15 grams form each admix was added separately to a coffee filter fitting a standard 4 cup coffee maker such as a Mr. Coffee® 4-Cup Dispenser (Sunbeam Products, Inc.) (or any non-progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com