Heat-curing epoxy resin composition containing non-aromatic ureas as accelerator

a technology composition, which is applied in the direction of epoxy resin coating, epoxy resin adhesive, lamination, etc., can solve the problems of great problems with the storage stability of heat-curing epoxy resin composition, and achieve good storage stability, rapid curing, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

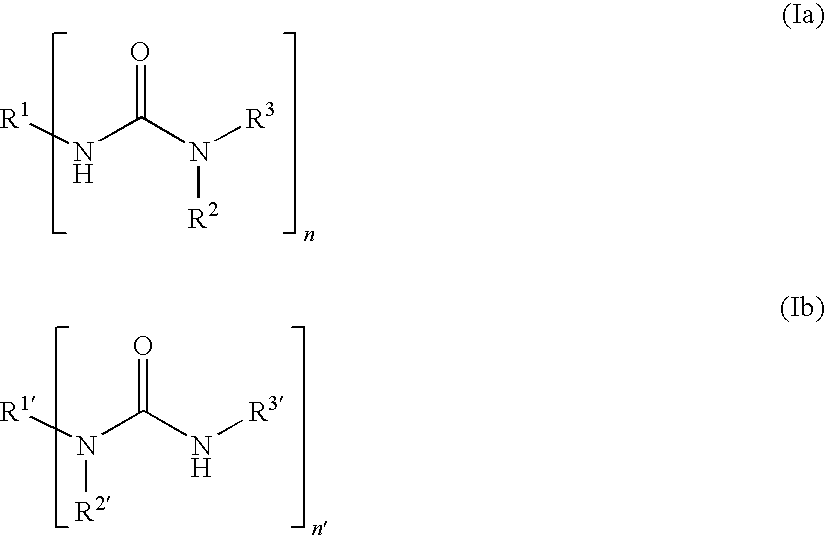

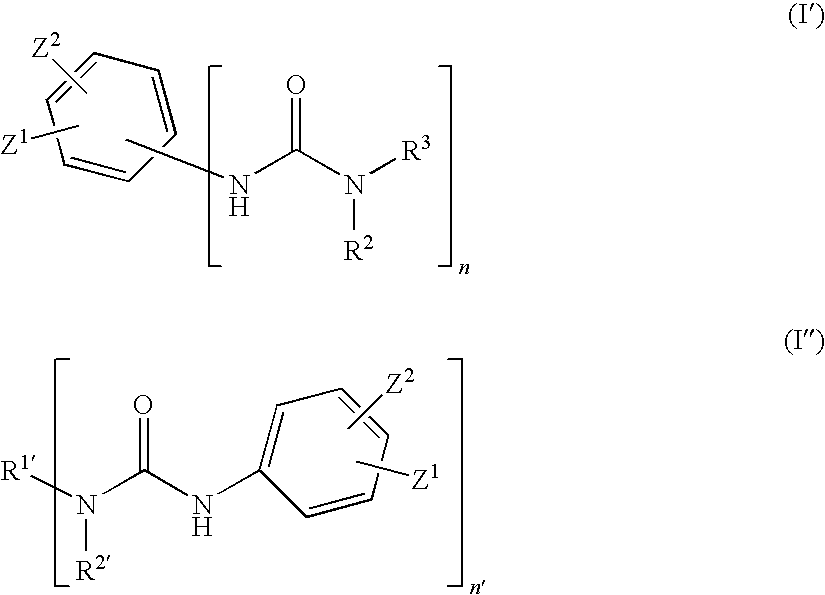

[0211]Curing Agents for Epoxy Resins

N,N-Dimethylurea (=1,1-dimethylurea) (“asym DMH”)

[0212]n=1, R1═H, R2═R3═CH3

[0213]N,N-Dimethylurea was obtained from Aldrich, Switzerland.

N′,N′-Dimethyl-N-butylurea (=3-butyl-1,1-dimethylurea) (“BuDMH”)

[0214]n=1, R1=n-butyl, R2═R3═CH3

[0215]50 ml of tetrahydrofuran (THF) and 20.0 g of an approximately 33% strength solution of dimethylamine in ethanol (Fluka) (about 146 mmol of amine) were charged to a 100 ml two-neck flask with reflux condenser. Subsequently, over 30 minutes, 14.5 g of butyl isocyanate (Fluka) (about 146 mmol of NCO) were slowly added dropwise, producing a slight exothermic response. After 3 hours of stirring at ambient temperature, the solvent was stripped off on a rotary evaporator at 80° C. under vacuum. This gave about 21.0 g of a slightly yellowish, low-viscosity liquid. The desired adduct was used further without other purification.

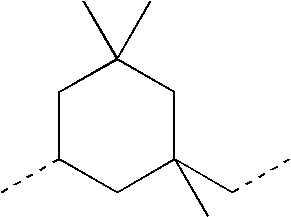

Hexamethylenebis(1,1-dimethylurea) (=1,1′-(hexane-1,6-diyl)bis(3,3-dimethylurea) (“HDIDMH”)

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com