Post sleeve assembly

a post sleeve and assembly technology, applied in the direction of identification means, ways, instruments, etc., can solve the problems of deterioration of wooden posts, difficult replacement of concrete anchoring posts, waste,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

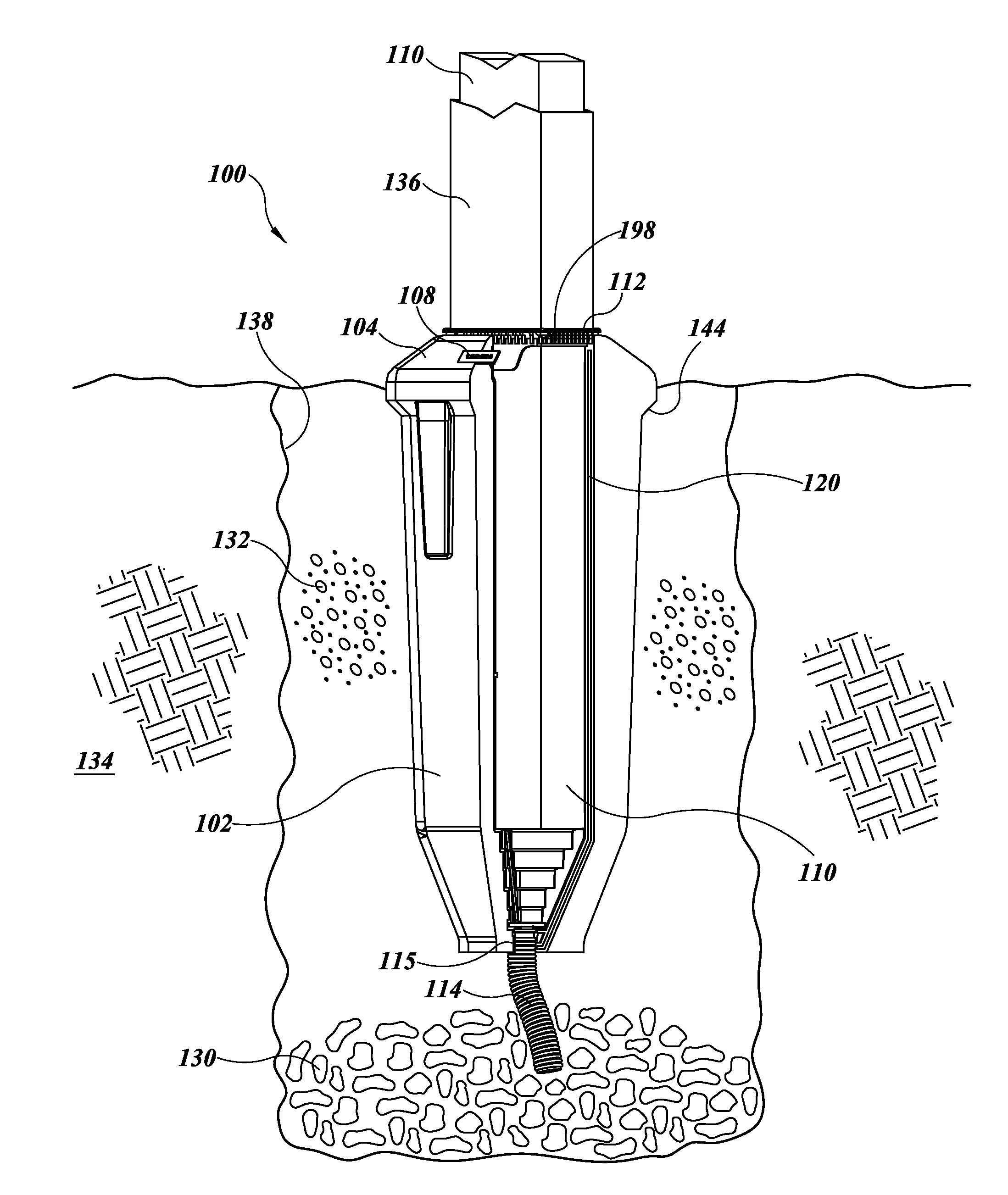

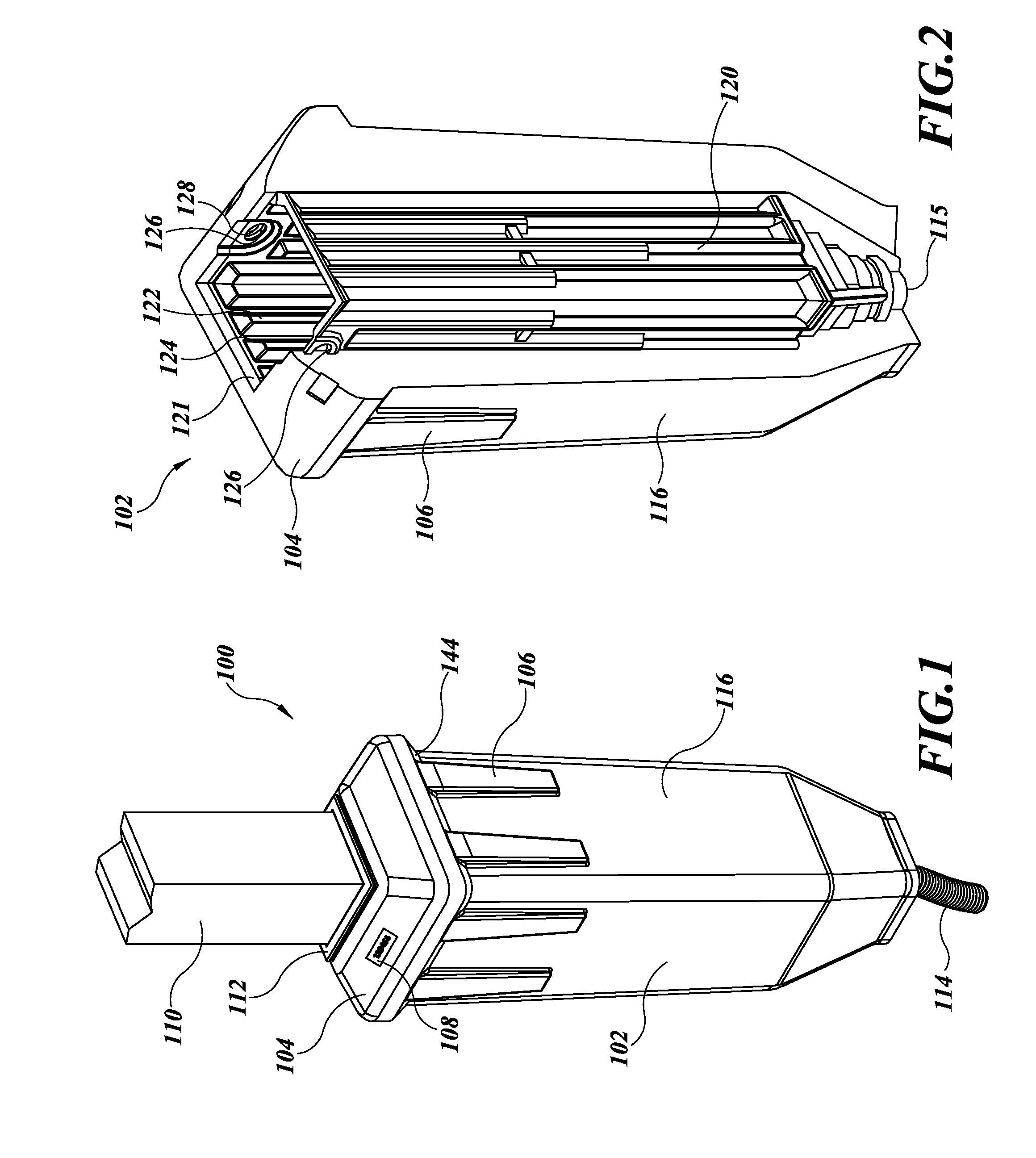

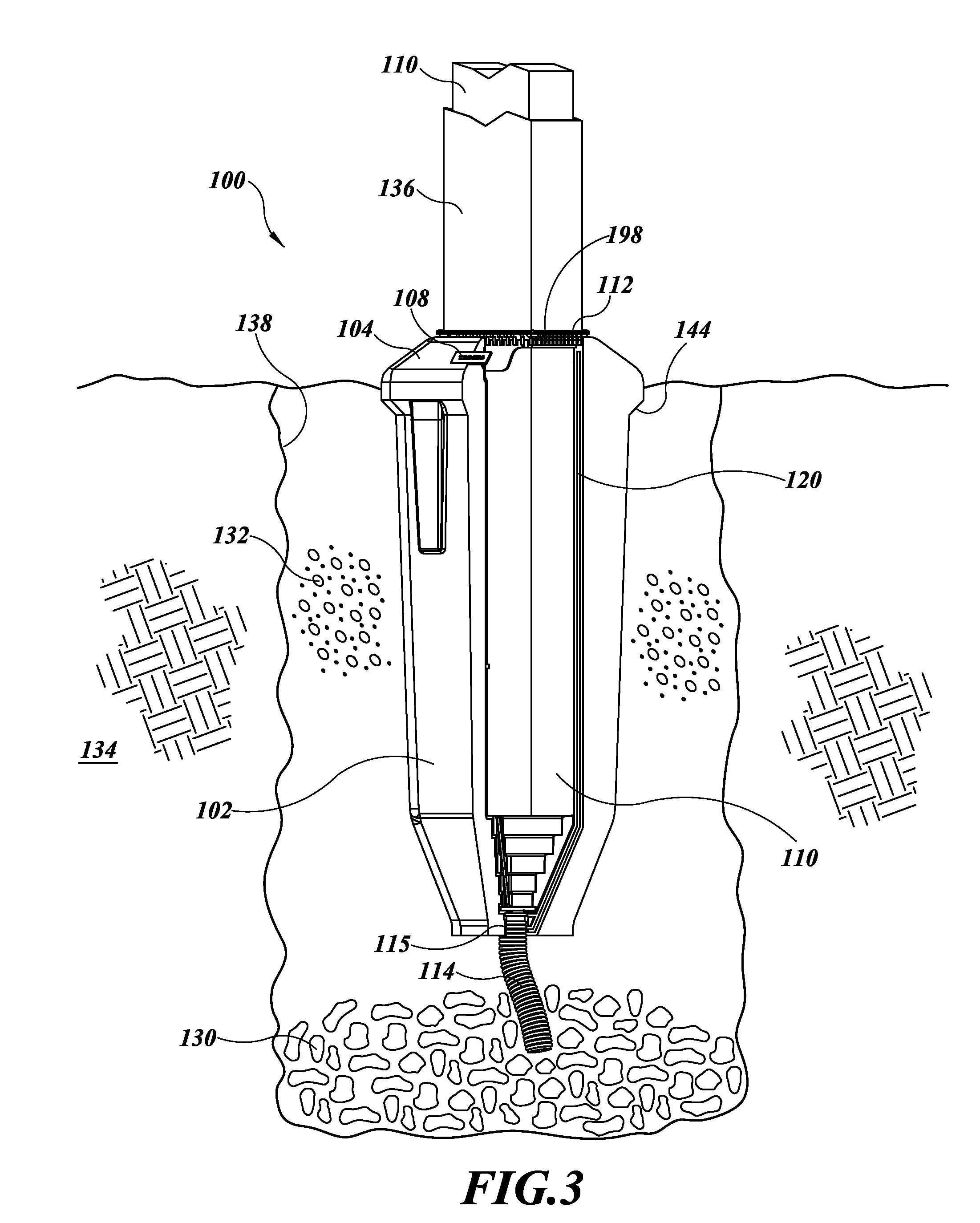

[0044]FIG. 1 shows a post sleeve assembly 100 according to a first embodiment. The post sleeve assembly 100 includes a post sleeve 102 having a body 116 with a somewhat tapered shape and a wide rim 104 extending outward from the body in each direction. Reinforcing ribs 106 extend from the body 116 to the underside or soffit 144 of the rim 104. A post 110 is shown positioned in the post sleeve 102. An upper surface of the rim 104 slopes downward, away from the post on all sides. An identification plate 108 is inset into an upper surface of the rim 104. A post collar 112 fits closely around the post and extends partway into an upper aperture 121 (see FIG. 2) of the post sleeve 102 providing a means to block insects, debris, and direct rain from infiltrating while maintaining substantial airflow to the post sleeve assembly and giving lateral support to the post from the supporting post sleeve 102.

[0045]The rim 104 is shown as having a smooth regular surface. According to other embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com