Generation of high octane hydrogen gas from acetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

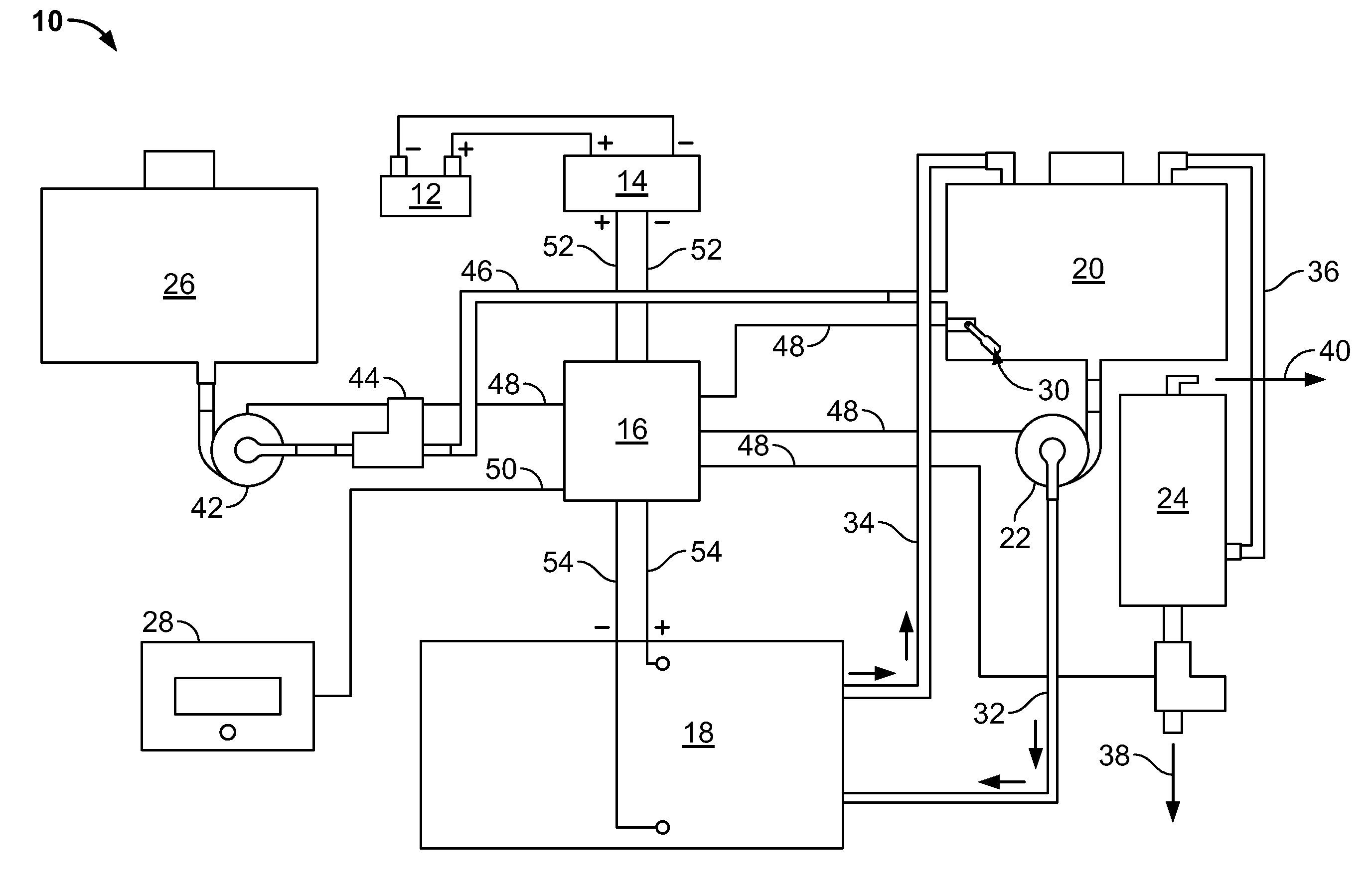

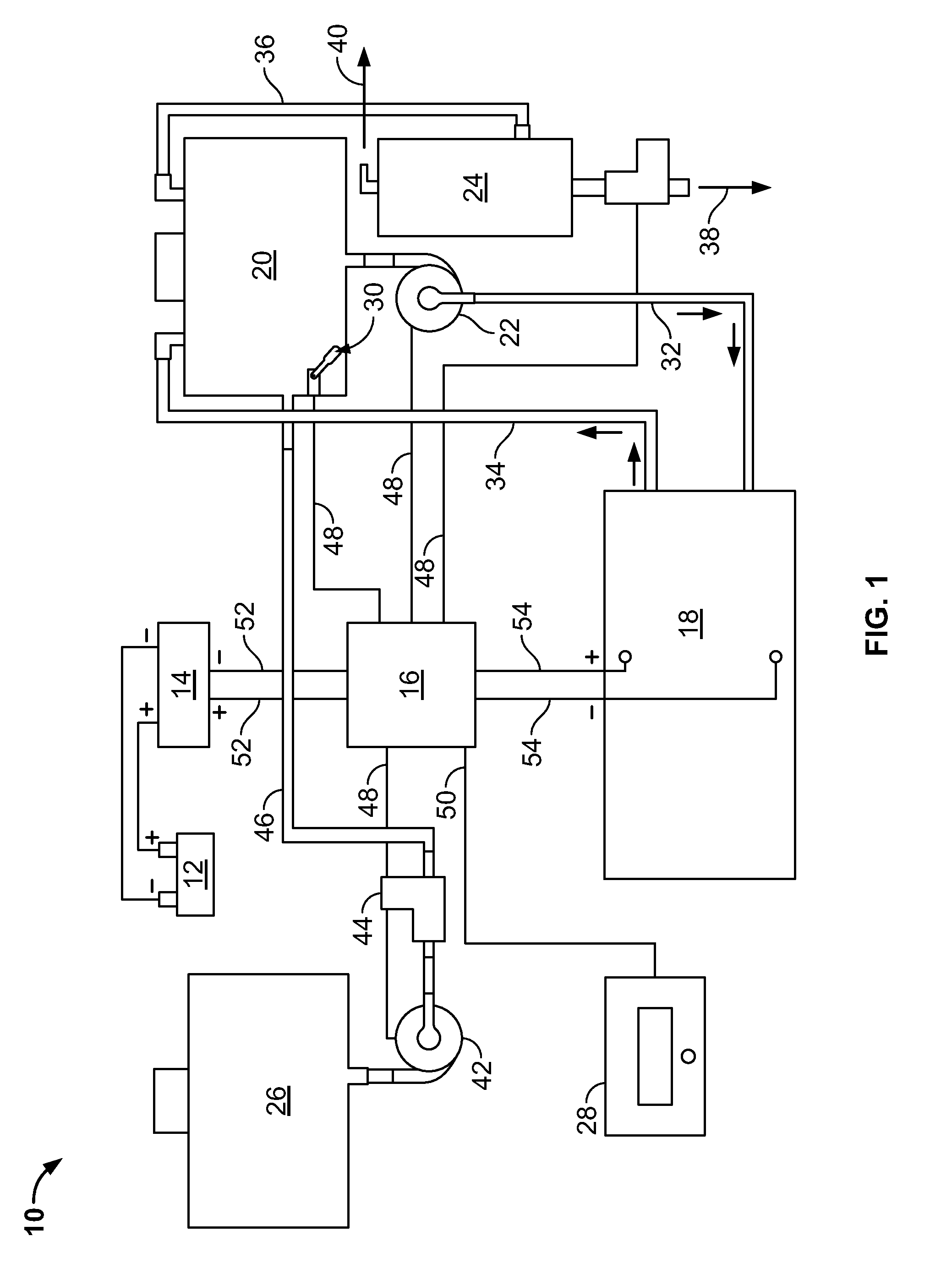

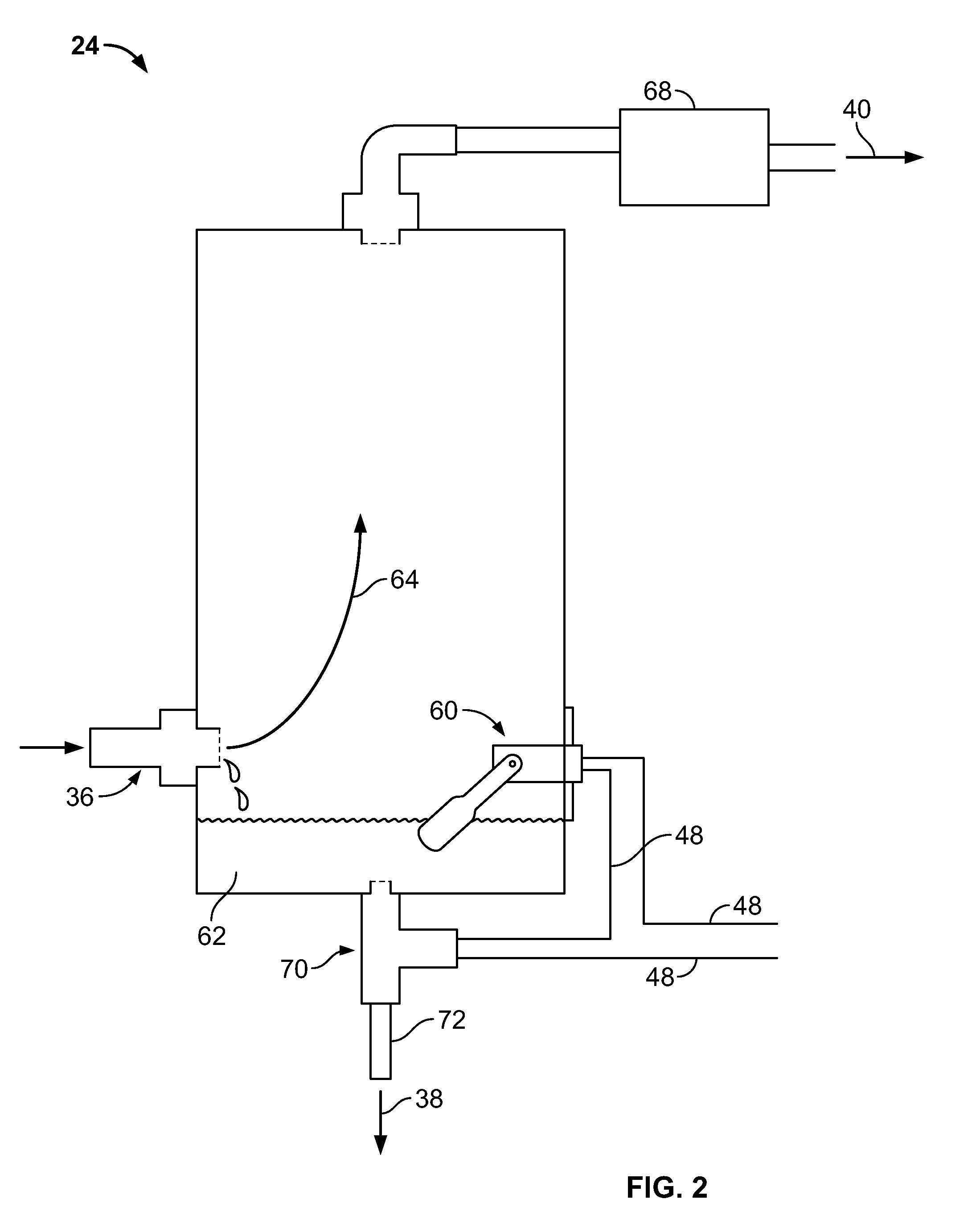

[0016]The preferred embodiment and other embodiments, which can be used in industry and include the best mode now known of carrying out the invention, are hereby described in detail with reference to the drawings. Further embodiments, features and advantages will become apparent from the ensuing description, or may be learned without undue experimentation. The figures are not necessarily drawn to scale, except where otherwise indicated. The following description of embodiments, even if phrased in terms of “the invention” or what the embodiment “is,” is not to be taken in a limiting sense, but describes the manner and process of making and using the invention. The coverage of this patent will be described in the claims. The order in which steps are listed in the claims does not necessarily indicate that the steps must be performed in that order.

[0017]An embodiment of the present invention generally generates high-octane hydrogen gas from acetic acid. Embodiments may provide, for exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com