Quiet hair dryer

a quiet, hair dryer technology, applied in the field of hair dryers, can solve the problems of fan blades creating substantial aerodynamic noise in combination with the surrounding structures, vibration of the motor to the housing, and inlet openings of hair dryers, and achieve the effect of suppressing the noise of air turbulen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

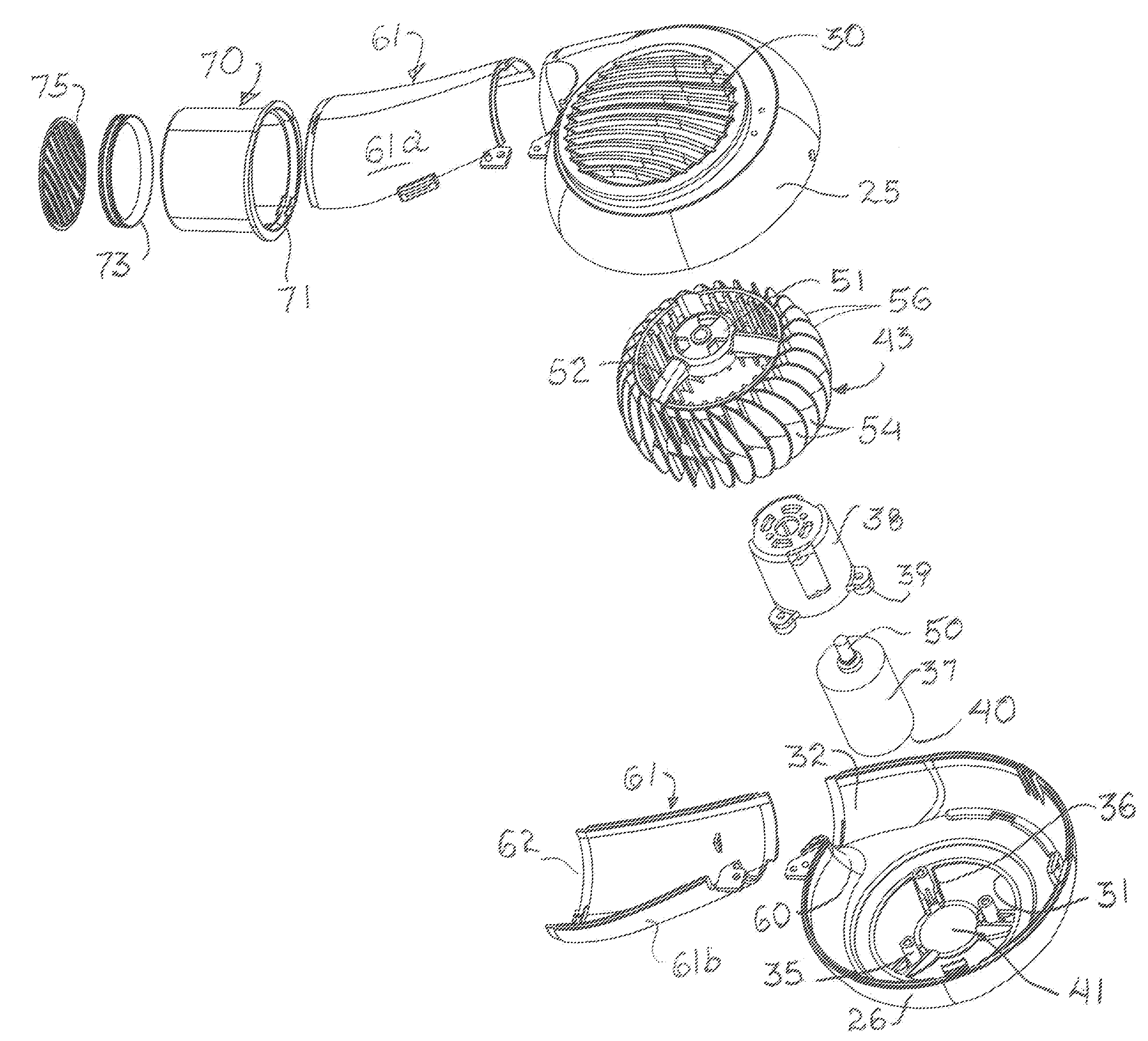

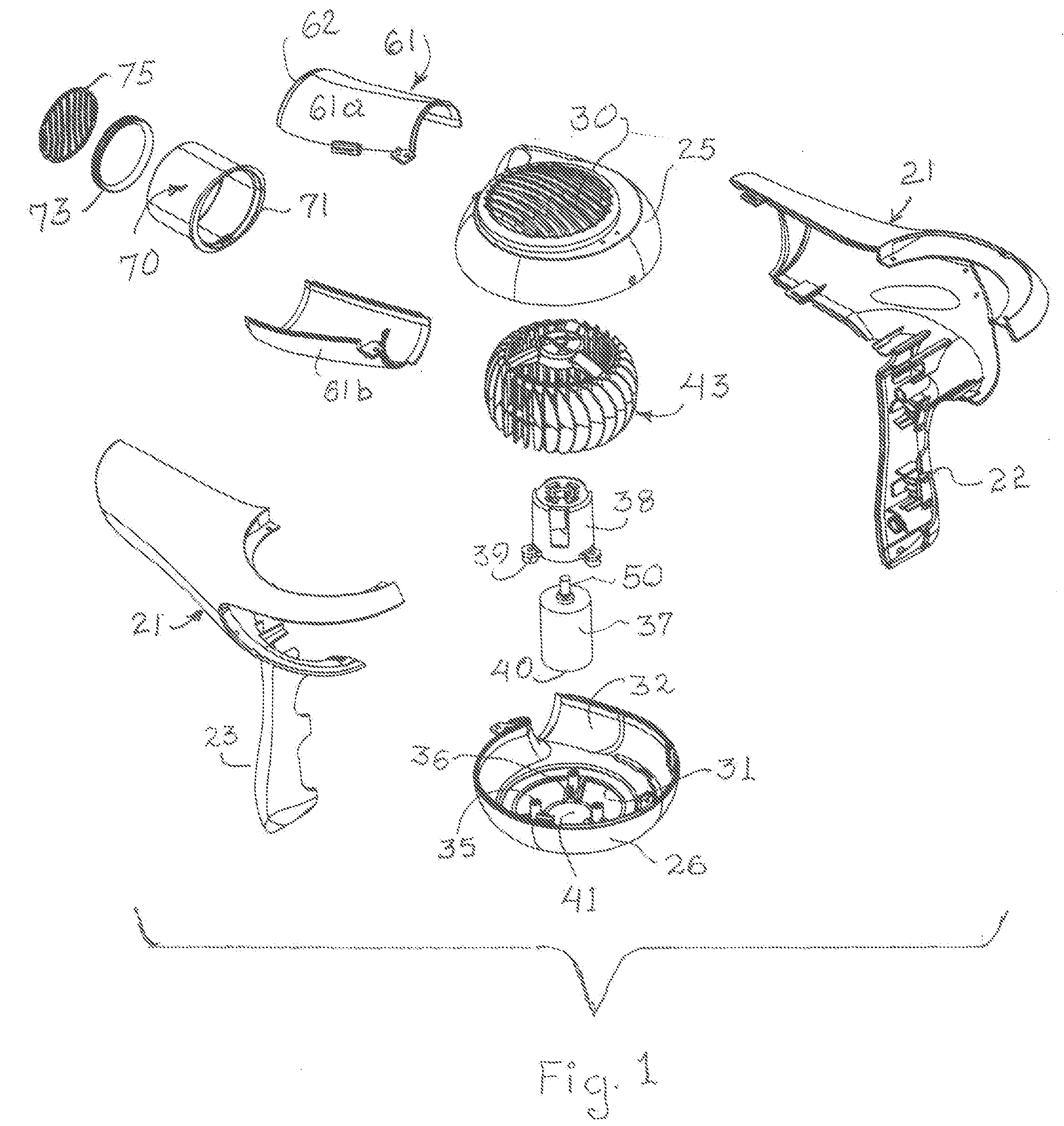

[0026]In FIG. 1, the major components of the quiet hair dryer 20, according this invention, are illustrated. A majority of its parts can be constructed of plastic or pressed metal. It has a handle assembly 21 consisting of a left shell 22 and a right shell 23 that inter lock to create a pistol like cradle for the blower (fan) assembly 24, shown in FIG. 2. This handle also includes recesses for the electrical switches and the electrical cord attachment (the switches and cord are not shown). The handle is designed so as not to impede balanced air flow into the blower assembly from both its top unit 25 and bottom unit 26, as discussed herein. It is important that the inflow of air to the blower assembly be balance from the top and from the bottom of the fan to eliminate aerodynamic noise which would, other wise, be generated from discordant air flows entering the blower assembly.

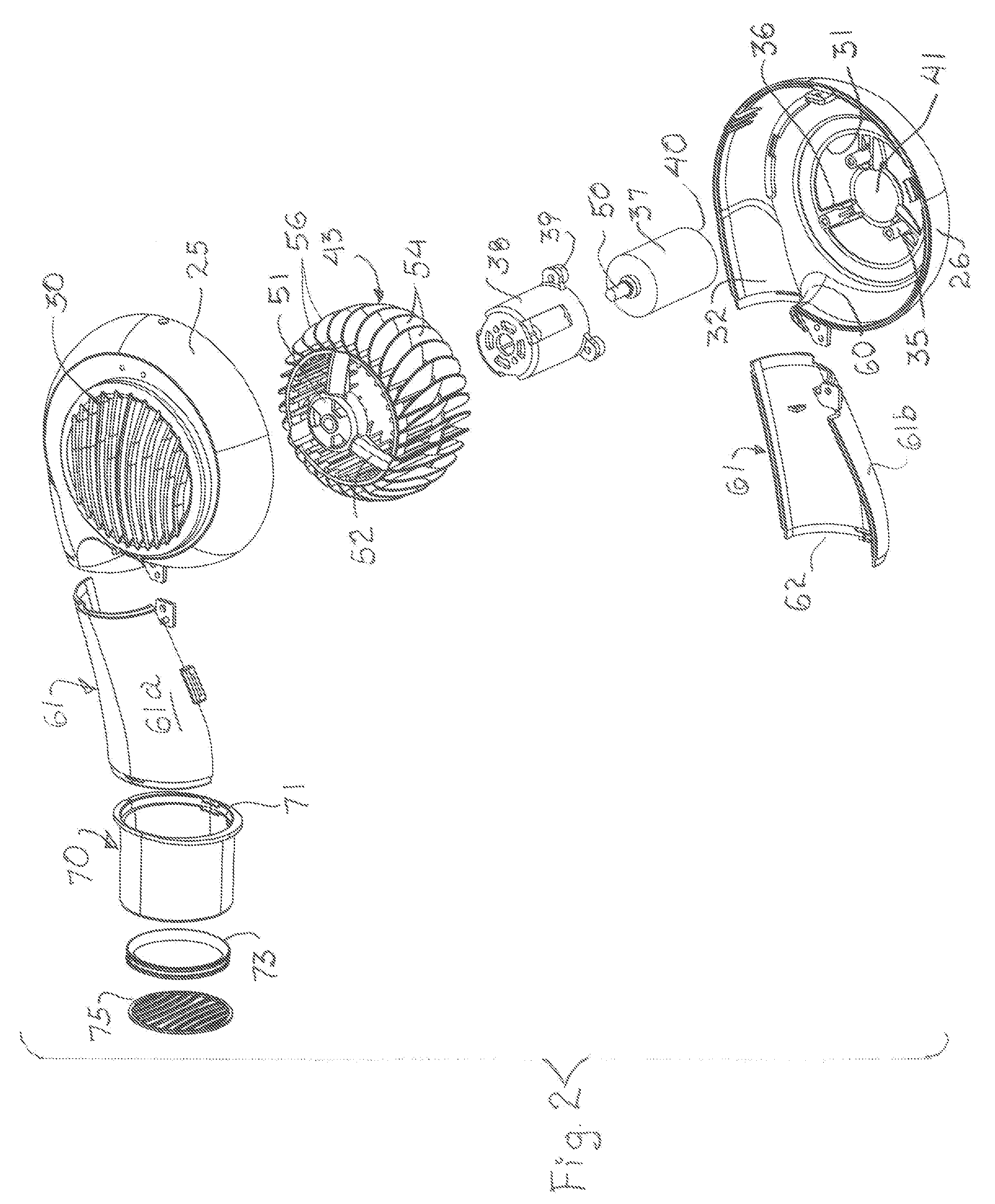

[0027]More particularly, the blower assembly 24 (refer to FIG. 2) is composed of the cupped top unit 25 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com