Apparatus for controlling integrated lighting ballasts in a series scheme

a technology of integrated lighting ballast and series scheme, which is applied in the direction of electric controllers, ignition automatic control, instruments, etc., can solve the problems of not being able to easily replace the light fixture and wall controls, not being able to tolerate many devices installed in close proximity, and not being able to achieve simple solutions for upgrading most legacy systems with plc-based lighting controls. , to achieve the effect of increasing data throughput, facilitating installation of the transmitter, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

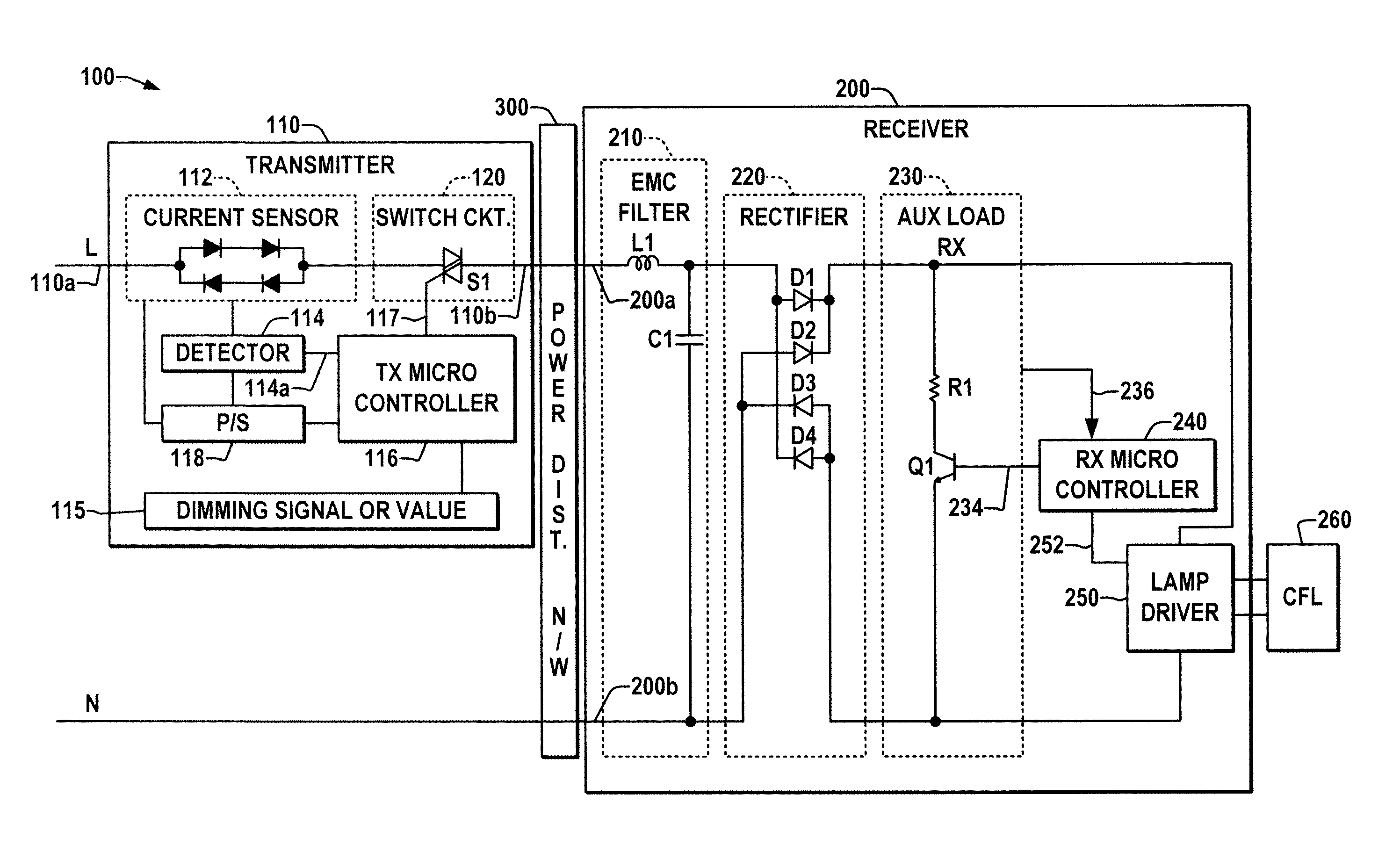

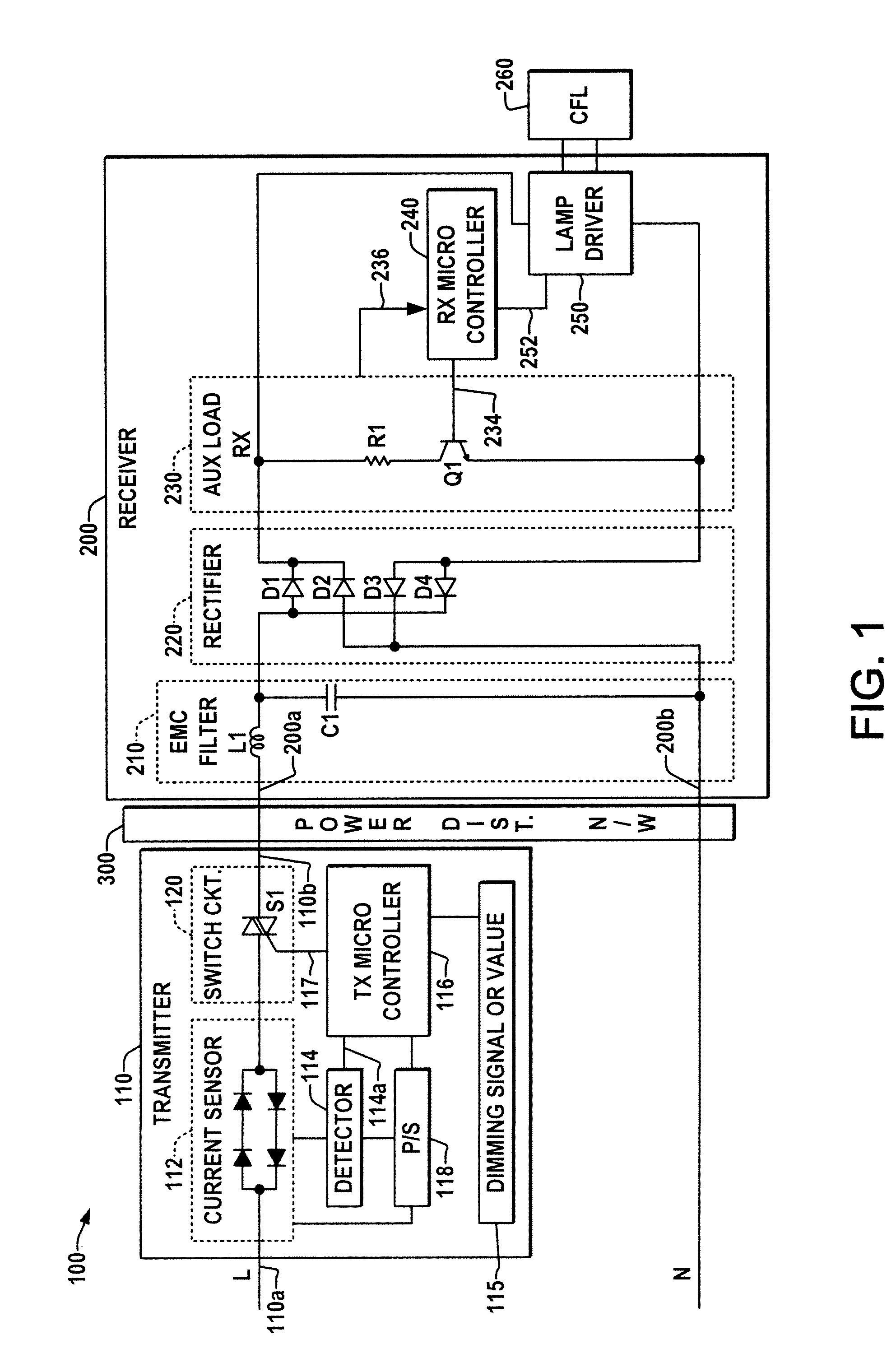

[0009]Referring now to the drawings, where like reference numerals are used to refer to like elements throughout, and wherein the various features are not necessarily drawn to scale, FIG. 1 illustrates a power line communication PLC system 100 that includes a transmitter 110 and a receiver 200 connected in series with one another by a power distribution network 300, such as legacy AC power wiring network in one example. The receiver 200 provides power to a compact fluorescent lamp (CFL) 260 via a lamp driver 250 in one example, but other forms of lighting devices may be driven by the receiver 200, including without limitation fluorescent tubes. The transmitter 110 includes an input 110a coupleable to a source of AC power, for example, such as a line (L) wire of a typical residential, commercial, industrial AC power wiring implementation, and an output 110b coupleable to a power distribution network 300, such as the wiring within walls etc. of the installation between a legacy switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com