Photochromic optical article

a photochromic and optical article technology, applied in the field of optical articles, can solve the problems of not being the best carrier to allow particular photochromatic dyes to achieve sufficiently fast color change and color fading rates, and inability to be used, etc., and achieve the effect of enhancing photochromic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Before the present invention is described in greater detail, it should be noted that the same reference numerals have been used to denote like elements throughout the specification.

[0019]The photochromic optical article of the present invention may be a lens (such as an eyeglass lens), a screen, a window, a protective plate, etc., and may be an element having a special function, such as a photochromic film / coating, a polarized lens, or a colored lens. The photochromic optical article of the present invention is not limited to the aforesaid disclosure.

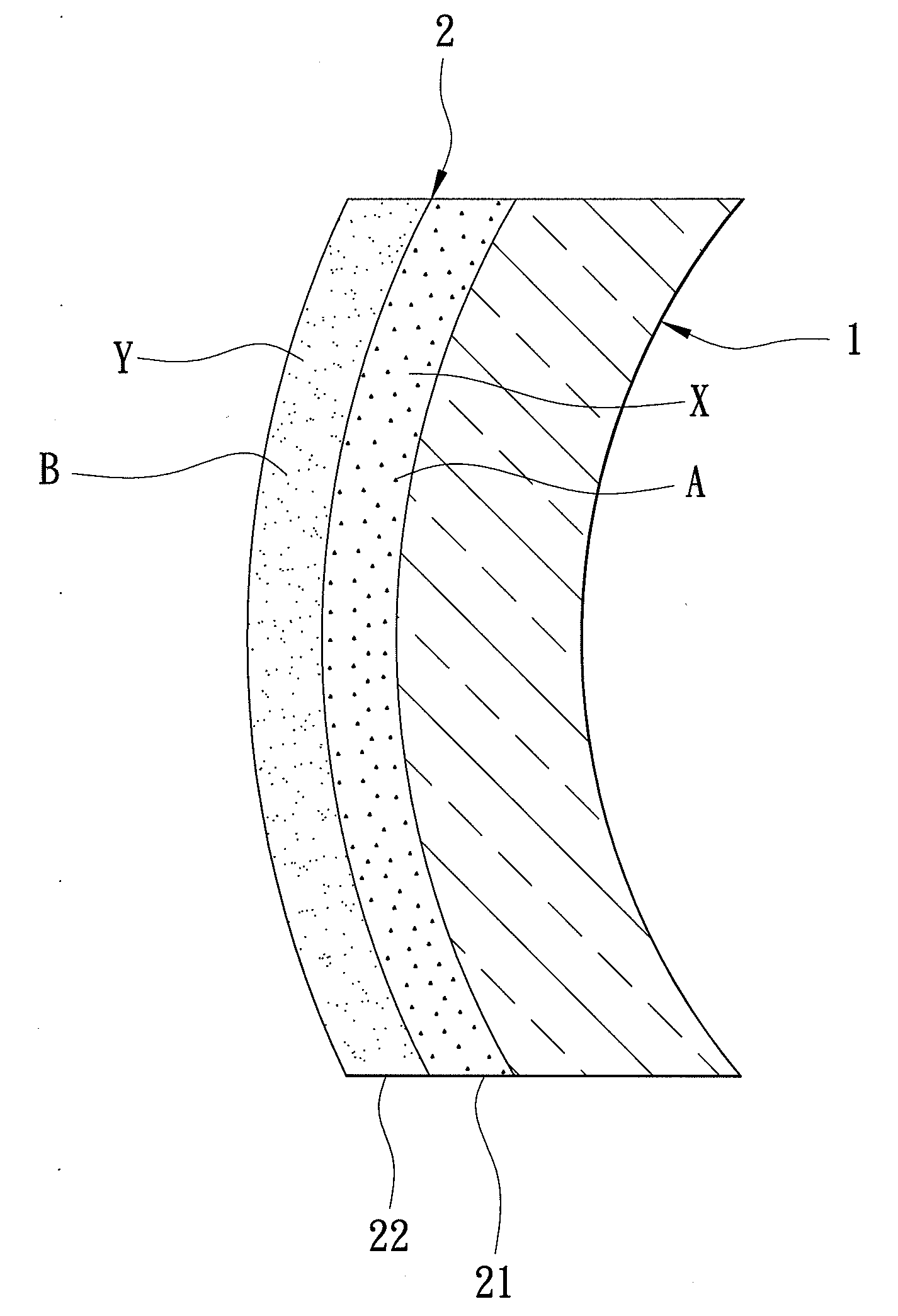

[0020]Referring to FIG. 3, a photochromic optical article according to the first preferred embodiment of the present invention is shown to comprise a substrate 1 and a photochromic coating 2.

[0021]The substrate 1 is a transparent or semi-transparent optical element, and may be made of a glass material, a ceramic material, or a plastic material, such as polycarbonate (PC), polymethylmethacrylate (PMMA), allyl diglycol carbonate res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photochromic | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| photochromic effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com