Acoustic resonance device

a technology of acoustic resonance and acoustic pressure, which is applied in the direction of vehicle arrangement, transportation and packaging, flooring, etc., can solve the problems of inability to demonstrate a high sound-absorbing effect at the seat position, and difficulty in sufficiently reducing low-frequency sound owing to engine sound of a vehicle, so as to reduce the sound pressure, and increase the particle velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

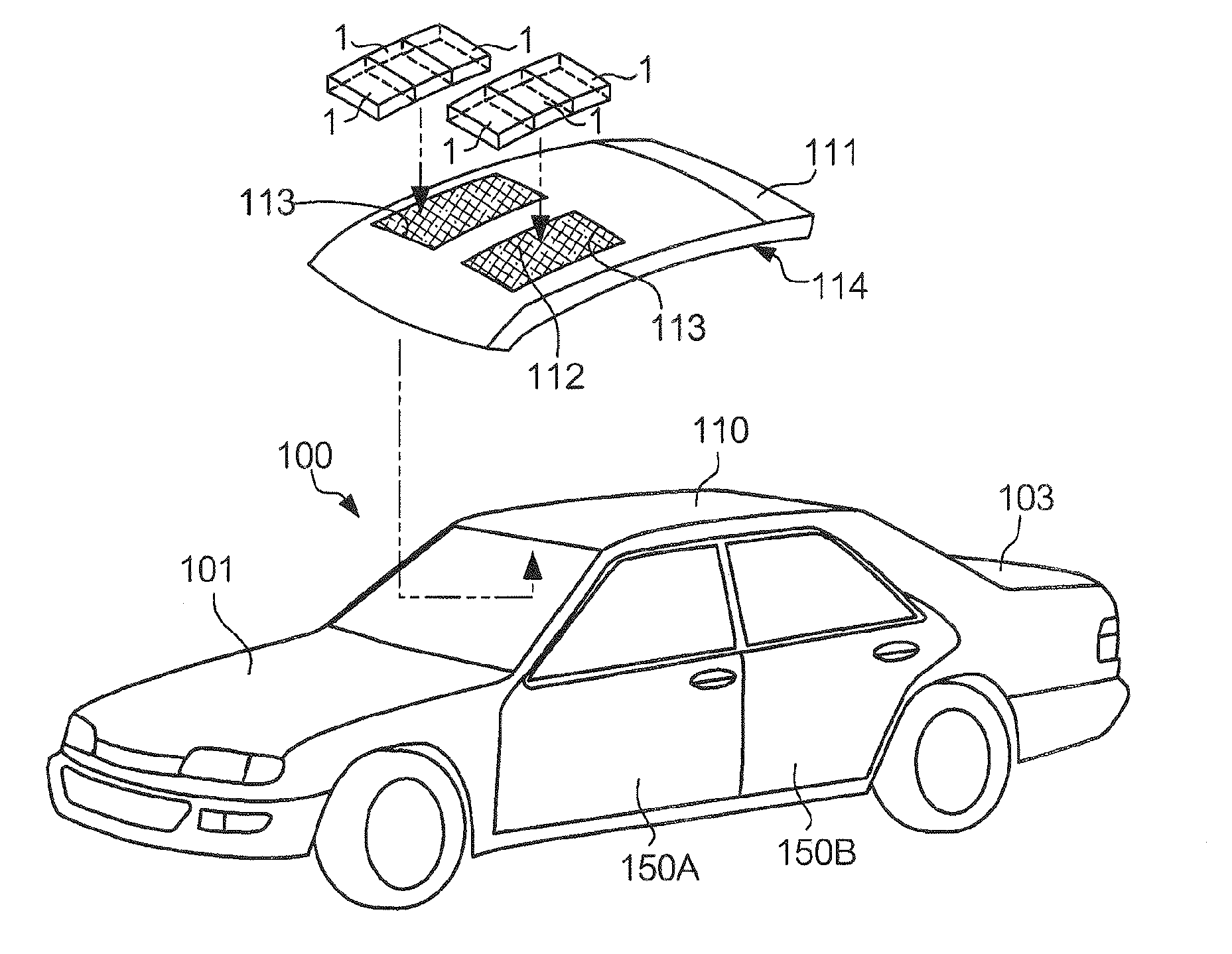

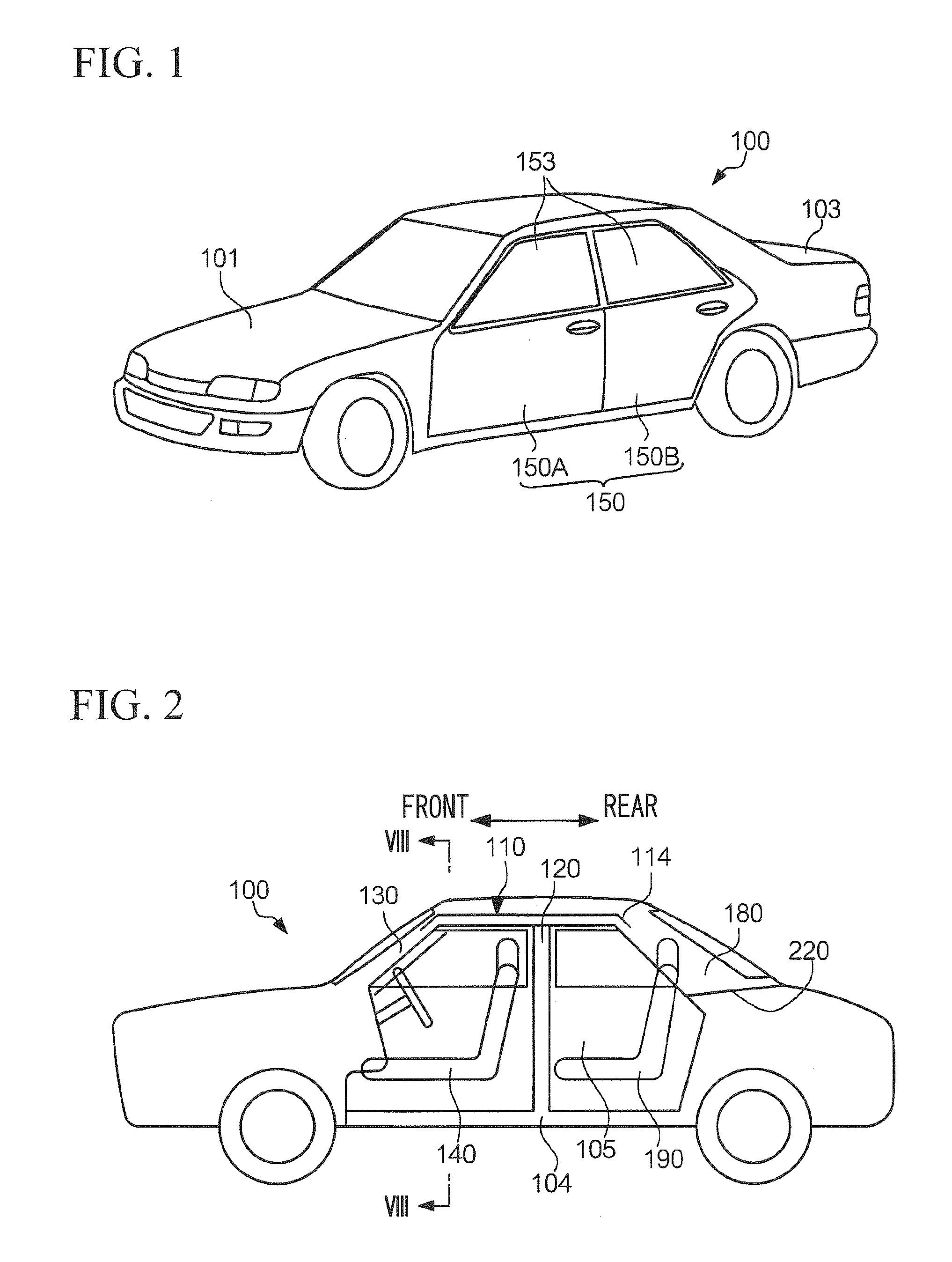

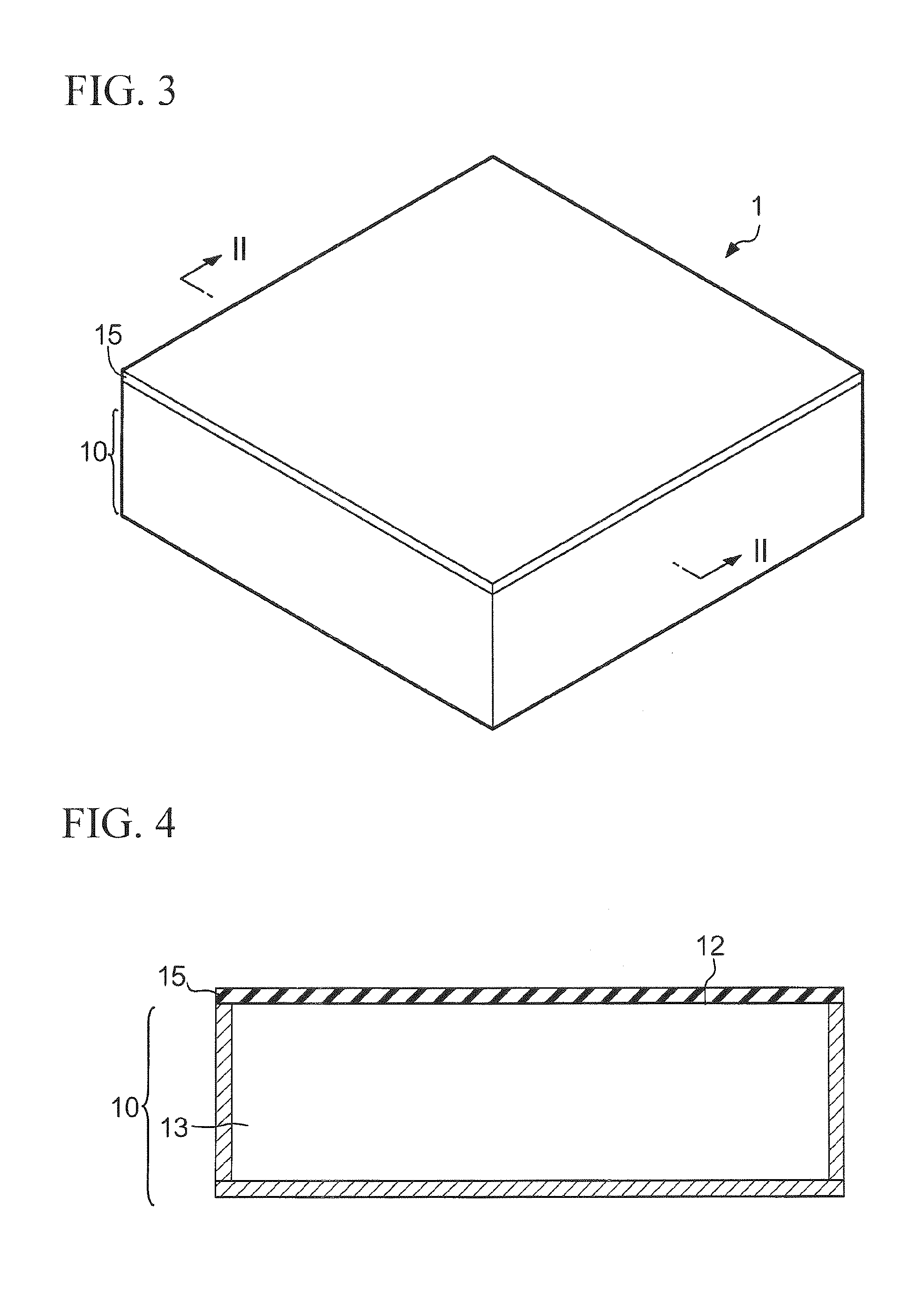

[0051]FIG. 1 is a perspective view showing the exterior appearance of a vehicle 100, i.e. a four-door sedan, equipped with an acoustic resonance device according to a first embodiment of the present invention. FIG. 2 diagrammatically shows a cabin / compartment 105 of the vehicle 100. Herein, a bonnet (hood) 101, four doors 150 (which serve as entrance doors of the compartment 105), and a trunk door 103 are fixed to a chassis (serving as a skeletal structure of the vehicle 100) in an open / close manner. The chassis of the vehicle 100 includes a base 104, center pillars 120 (which extend upwards from the base 104), front pillars 130, and rear pillars 180 as well as a part of a roof 110 (which is supported by those pillars). The compartment 105 is circumscribed by the doors 150 in the vehicle 100. The compartment 105 is a room space accommodating a driver / passenger who gets into the vehicle 100. A rear package tray 220 is installed in the rear side of the vehicle 100. ...

second embodiment

2. Second Embodiment

[0099]Next, a second embodiment of the present invention will be described with respect to an acoustic resonance device installed in the vehicle 100, which is constituted of a resonance pipe unit 2 including resonance pipes.

[0100]FIGS. 14A and 14B show the constitution of the resonance pipe unit 2. FIG. 14A shows the exterior appearance of the resonance pipe unit 2, which is constituted of five resonance pipes 21 (i.e. 21-1 through 21-5). The resonance pipes 21 are aligned in an alignment direction perpendicular to their longitudinal direction, wherein they are unified together via fixing measures or adhesive. The resonance pipes 21 are each composed of a metal or a synthetic resin, which is shaped in a pipe form. Each of the resonance pipes 21 is constituted of a closed end 22, an open end 23 and a hollow space 25; hence, it is a closed pipe having one open end and one closed end. The open ends 23 of the resonance pipes 21 are linearly aligned so as to adjoin to...

third embodiment

3. Third Embodiment

[0119]A third embodiment of the present invention is characterized by using a Helmholtz resonator 3, which is installed in the compartment 105. The third embodiment is similar to the first embodiment with respect to the overall structure of the vehicle 100 and the installation positions of resonators in the compartment 105, wherein the same constituent elements are designated the same numerals accompanied with a subscript “b”; hence, a detailed description thereof will be omitted.

[0120]The Helmholtz resonator 3 is employed as an acoustic resonance device of the third embodiment. FIG. 20A is a perspective view showing the exterior appearance of the Helmholtz resonator 3, and FIG. 20B is a cross-sectional view taken along line E-E in FIG. 20A. The Helmholtz resonator 3 is constituted of a body 31 and a tubular portion 32. A hollow space is formed inside the body 31 and the tubular portion 32 and communicates with an opening 33 of the tubular portion 32.

[0121]A cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com