Cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

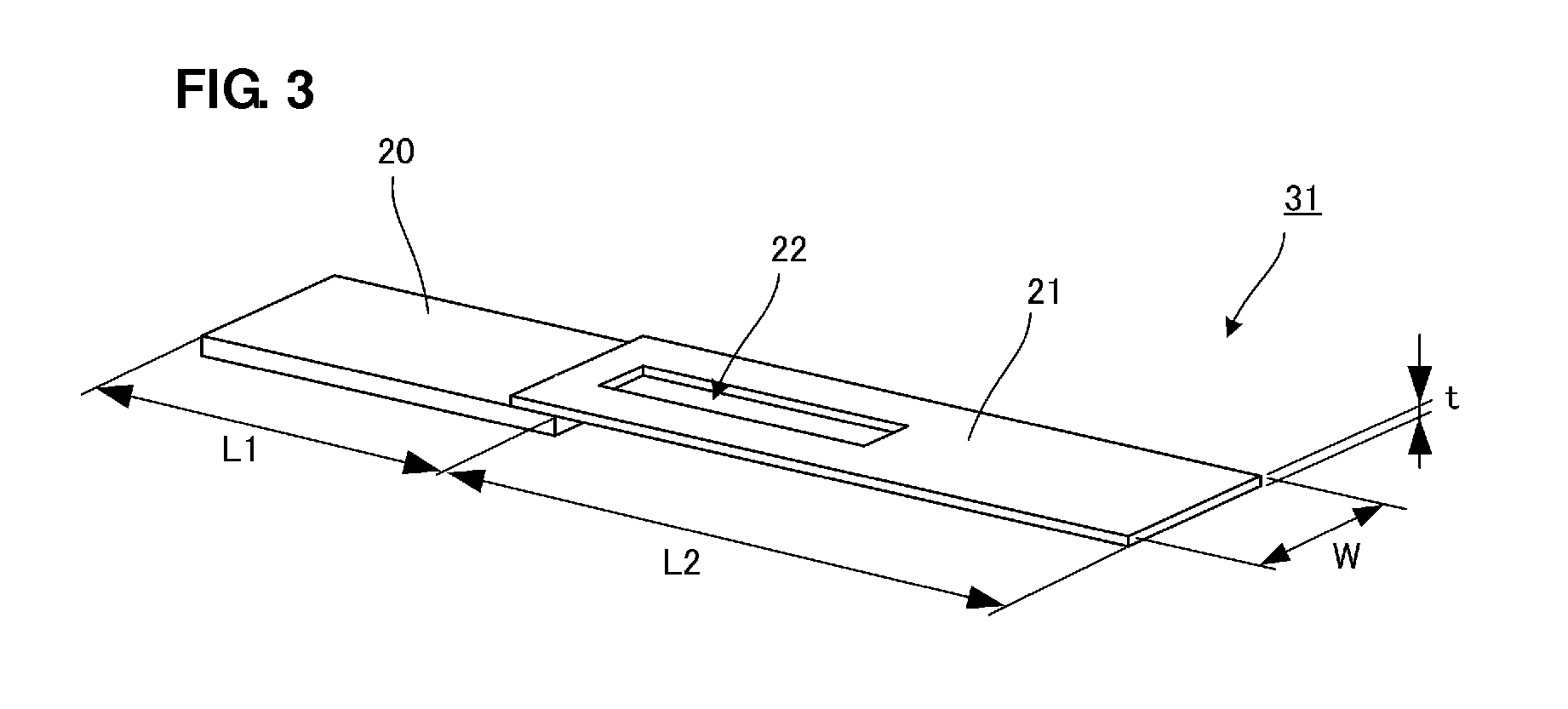

[0057]FIG. 3 is a perspective view of a piezoelectric fan for use in a cooling device according to a first preferred embodiment of the present invention. In FIG. 3, a piezoelectric fan 31 includes a blade 21 and a piezoelectric oscillator 20. The blade 21 includes a hole 22. The piezoelectric oscillator is preferably a bimorph piezoelectric oscillator in which a piezoelectric element is arranged on each of two opposed surfaces of a metal plate defining intermediate electrode. That is, each of the piezoelectric elements on both surfaces of the metal plate defining the intermediate electrode of the piezoelectric oscillator 20 includes an electrode film provided on its surface, and polarization is performed such that each of the piezoelectric elements is caused to oscillate by being bent in the longitudinal direction (L1 dimension direction) by the application of a driving voltage corresponding to a polarization direction of the piezoelectric element to the electrode and the metal plat...

second preferred embodiment

[0081]In the first preferred embodiment, the blade 21 includes the single hole 22 extending along the longitudinal direction of the blade. FIGS. 8A and 8B illustrate two configurations of a piezoelectric fan that are different from that of the first preferred embodiment.

[0082]The example shown in FIG. 8A illustrates a piezoelectric fan 32 in which the blade 21 preferably includes a cut 23 extending along the longitudinal direction of the blade 21 at an end thereof (farther from the piezoelectric oscillator 20). In the structure illustrated in FIG. 8A, the hole is arranged at the end of the blade 21. As described above, when the cut 23 is disposed at the end of the blade 21, the effect of increasing the amplitude of the blade 21 resulting from a reduction in air resistance and the effect of sweeping high-temperature air on the walls of the heat dissipating fins are obtained.

[0083]In the example shown in FIG. 8B, a piezoelectric fan is configured such that the blade 21 having a plural...

third preferred embodiment

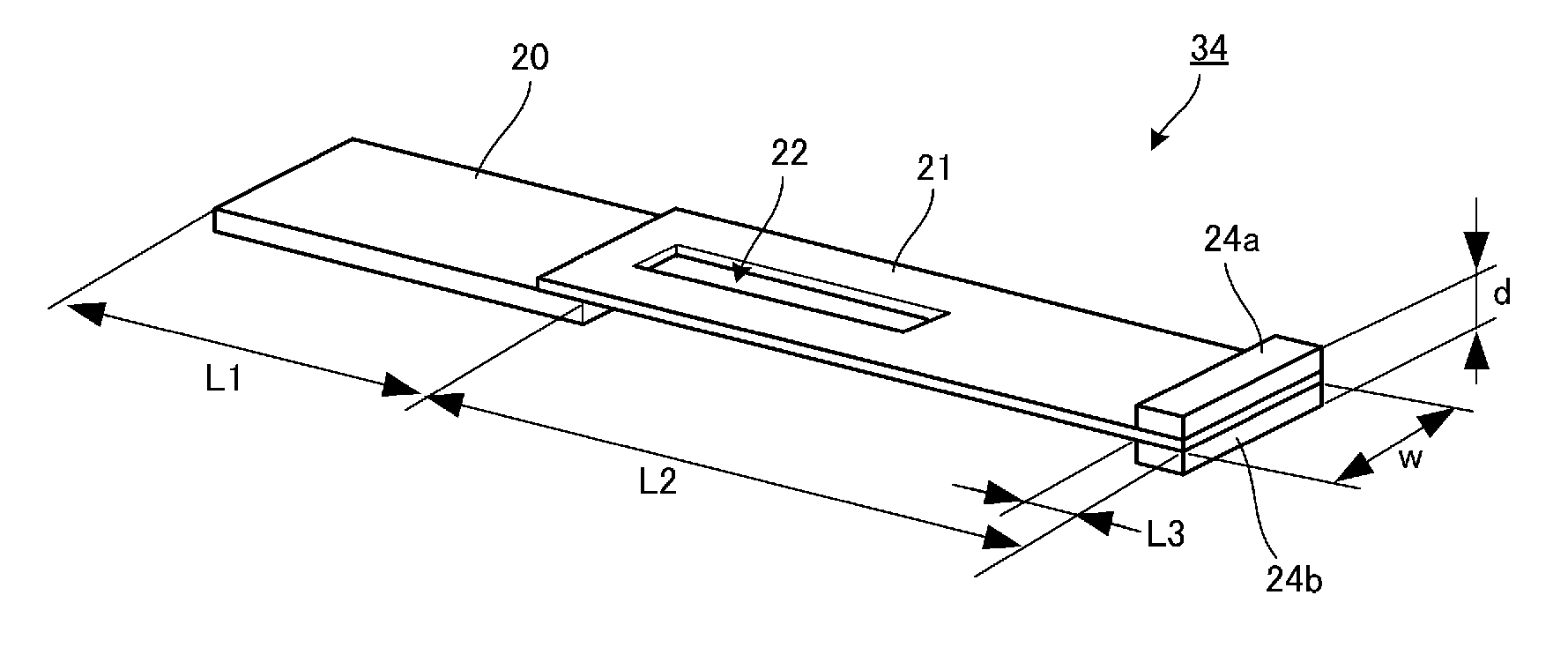

[0090]FIG. 9 is a perspective view of a piezoelectric fan for use in a cooling device according to a third preferred embodiment of the present invention. In this example, the blade 21 including the hole 22 and weights 24a and 24b disposed at the end and the piezoelectric oscillator 20 define a piezoelectric fan 34.

[0091]The weights 24a and 24b are preferably made of the same or substantially the same stainless steel as the blade 21 and are joined thereto by adhesive, for example. The dimensions L3 and d of the weights 24a and 24b illustrated in the drawing are preferably about 2 mm and about 0.5 mm, respectively, for example. The thickness dimension of the blade 21 preferably is about 100 μm, for example. The other dimensions L1, L2, and W are the same or substantially the same as in the first preferred embodiment illustrated in FIG. 3: L1=about 12 mm, L2=about mm, and W=about 6 mm, for example. The location and dimensions of the hole 22 are the same or substantially the same as in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com