Apparatus and method for monitoring and regulating cryogenic cooling

a technology of cryogenic cooling and apparatus, applied in the direction of domestic cooling apparatus, container discharge method, instruments, etc., can solve the problems of inability to contact-based temperature measurement, difficult direct sensing of workpiece surface temperature and tool surface temperature in metalworking applications, and inability to achieve contact-based temperature measuremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

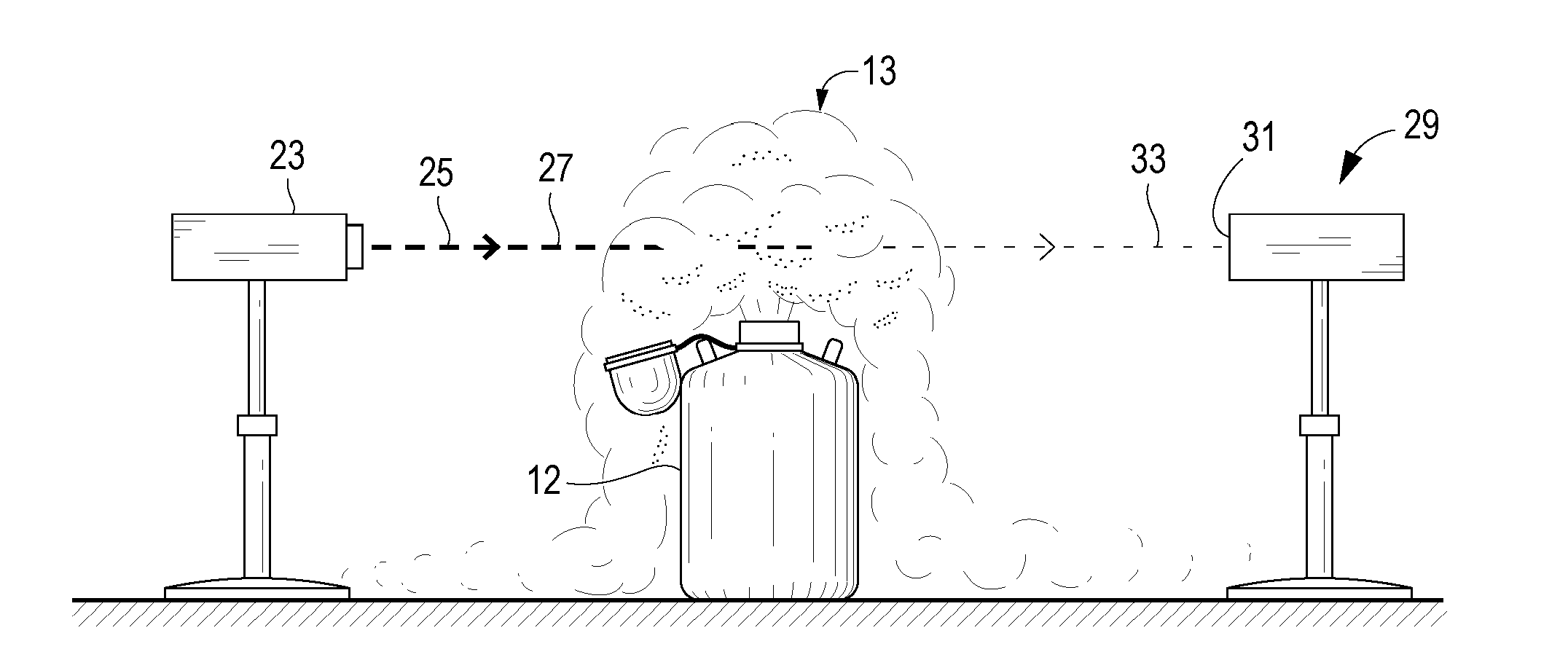

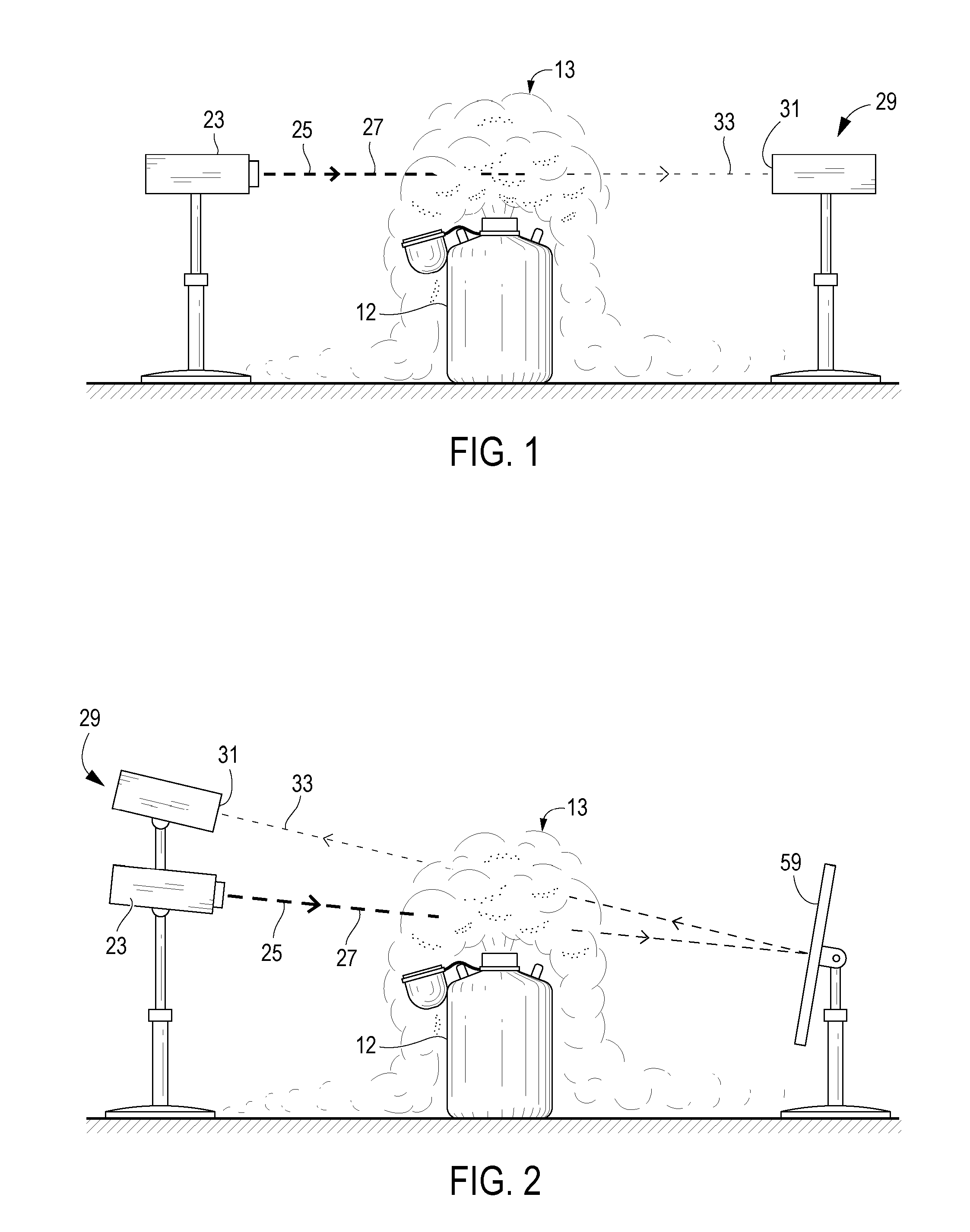

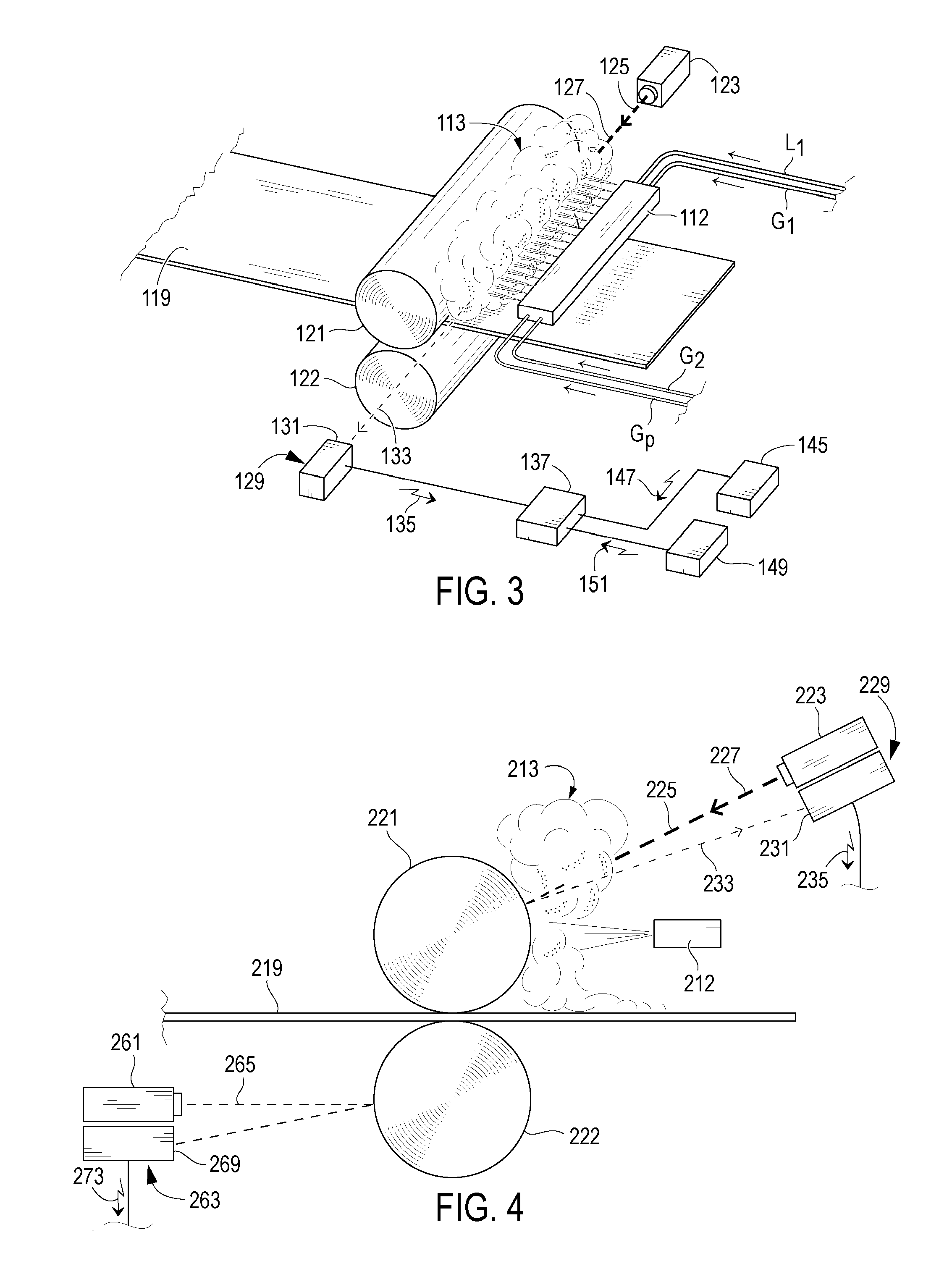

[0014]The present invention is an apparatus for use with a system having a cryogenic cooling component that generates a vapor cloud when operating. Systems that have a cryogenic cooling component may include, but are not limited to, metal rolling and machining operations such as lathe turning, boring, milling, thermal spray coating applications, and food freezing applications.

[0015]“Cryogenic vapor” is a suspension of microscopic water ice crystals which forms when water contained in ambient air comes in contact with a cryogenic spray, such as liquid nitrogen (hereinafter “LIN”), gaseous nitrogen, argon and carbon dioxide or a mixture of two or more of these liquids and / or gases. Cryogenic vapor is typically white and opaque or semi-opaque.

[0016]During experiments relating to the development of the present invention, it was observed that the amount of “cryogenic vapor” evolving from an area in which a cryogenic spray is being directed onto a substrate, e.g. workpiece and / or tool are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com