Femoral reaming system and method of performing trial reduction

a reaming system and femoral technology, applied in the field of surgical devices, can solve the problems of inexact reamer, series of potential problems, and laborious system, and achieve the effects of increasing accuracy, reducing the number of steps/instruments, and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

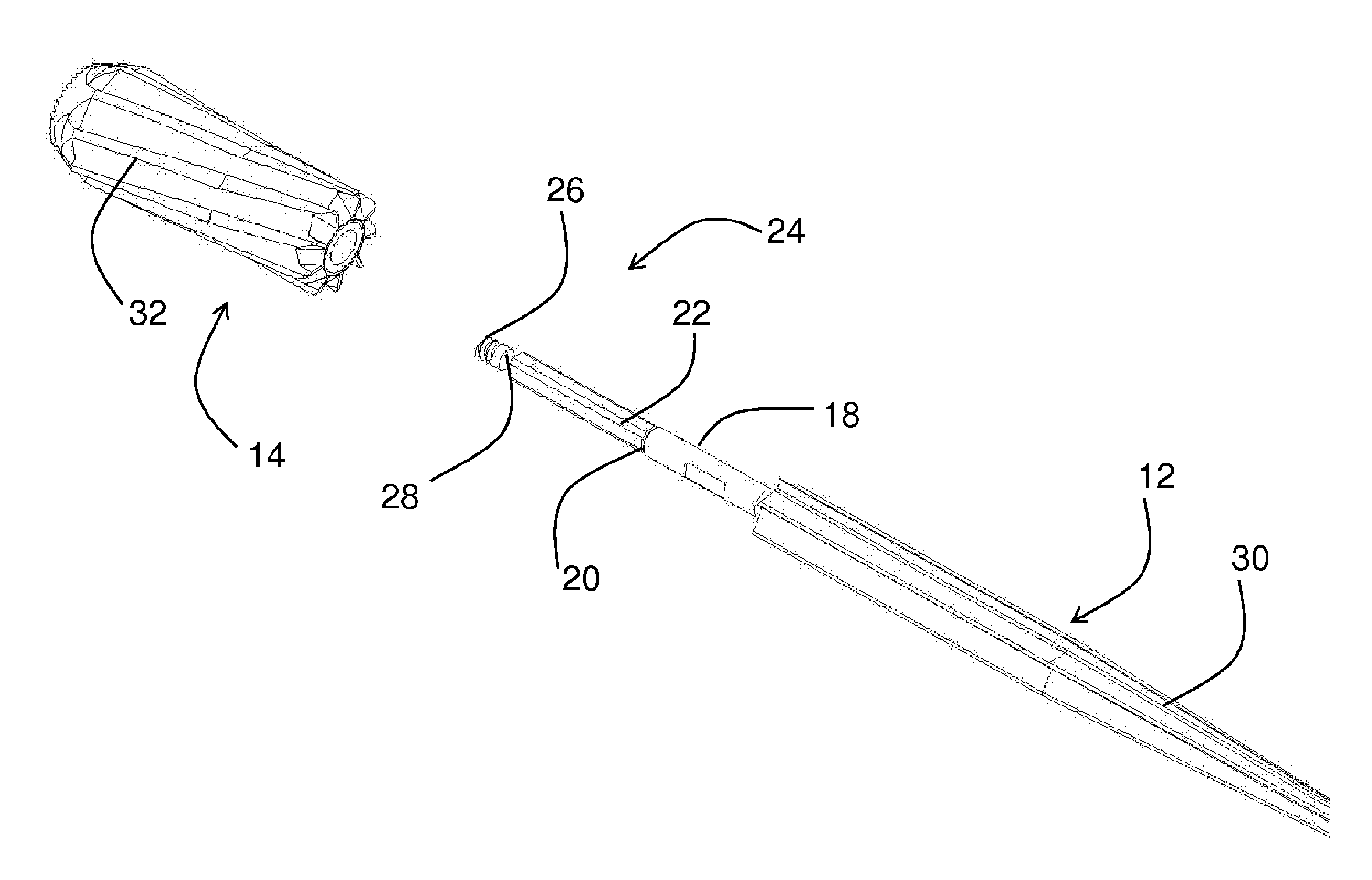

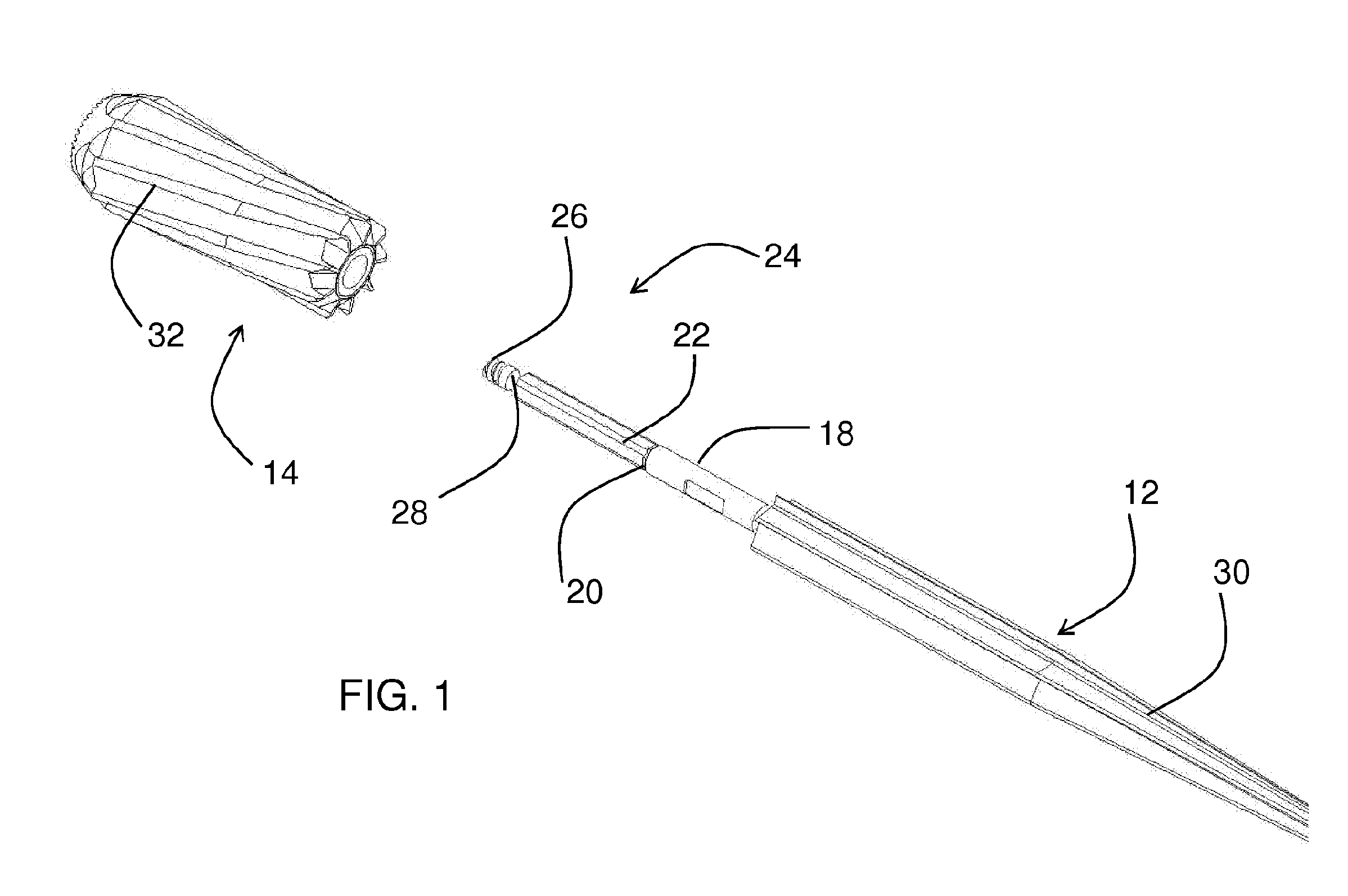

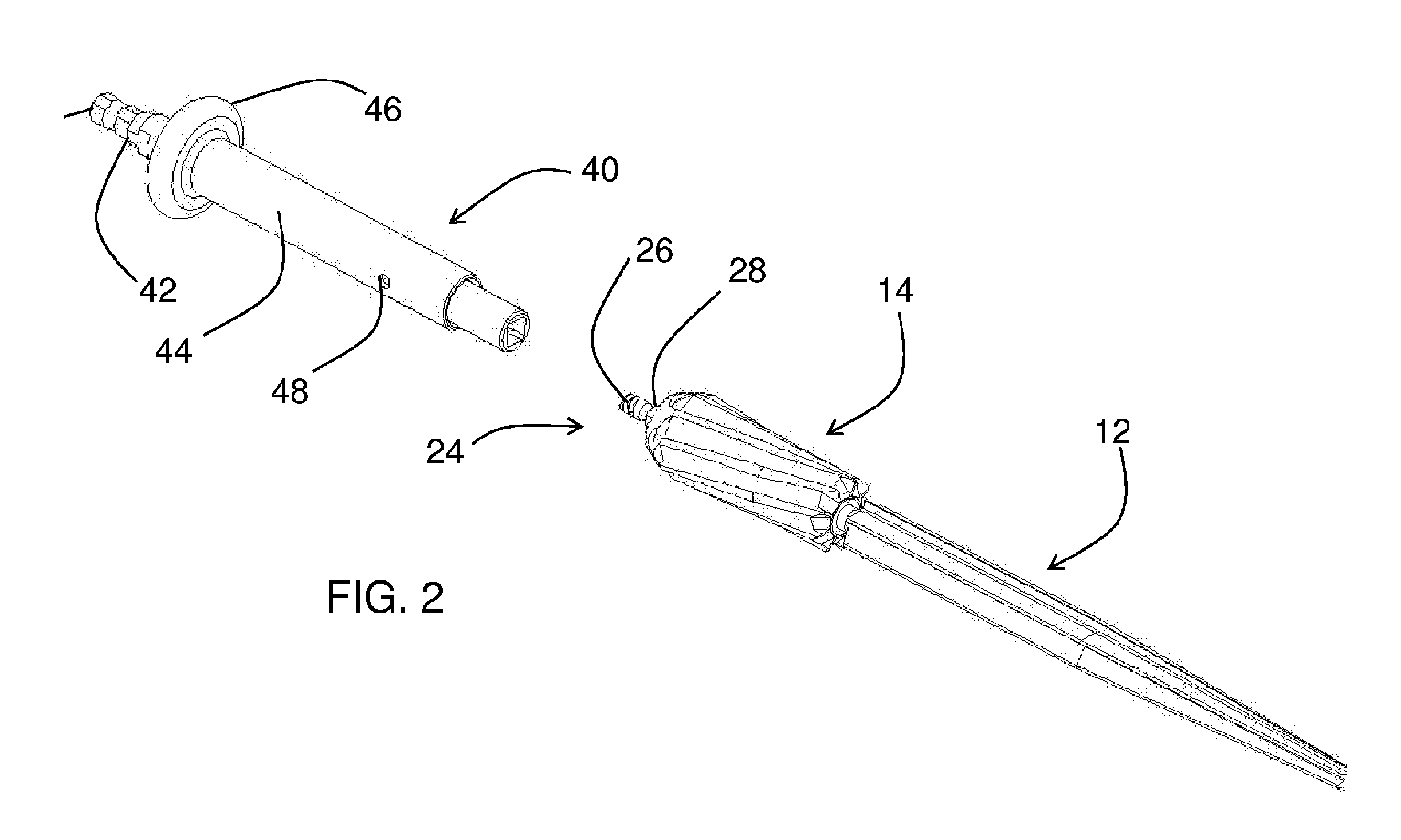

[0050]Referring to the accompanying drawings in which like reference numbers indicate like elements, FIG. 1 is an exploded view of parts of a femoral reamer 10 according to an embodiment of the invention. The femoral reamer 10 includes two major components, a distal reamer 12 and a proximal reamer 14. The distal reamer 12 prepares the femur for receiving a stem of a femoral implant and the proximal reamer 14 prepares the femur for receiving a sleeve of a femoral implant. The distal reamer 12 includes a thick depth shaft 18, a shoulder 20, a distal reamer shaft 22 and a quick connect mating portion 24. The quick connect mating portion 24 includes a mounting tip 26 and a groove 28. The quick connect mating portion 24 is attached to a drill.

[0051]The distal reamer 12 includes right-hand cutting flutes 30 while the proximal reamer 14 includes left-handed cutting flutes 32. The right-handed cutting flutes 30 have edges on the flutes that cut in a forward cutting action when the reamer 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com