Cooling Module

a technology of cooling module and cooling chamber, which is applied in the direction of semiconductor devices for light sources, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of low cooling efficiency, loud noise, and still has drawbacks, and achieve the effect of reducing disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

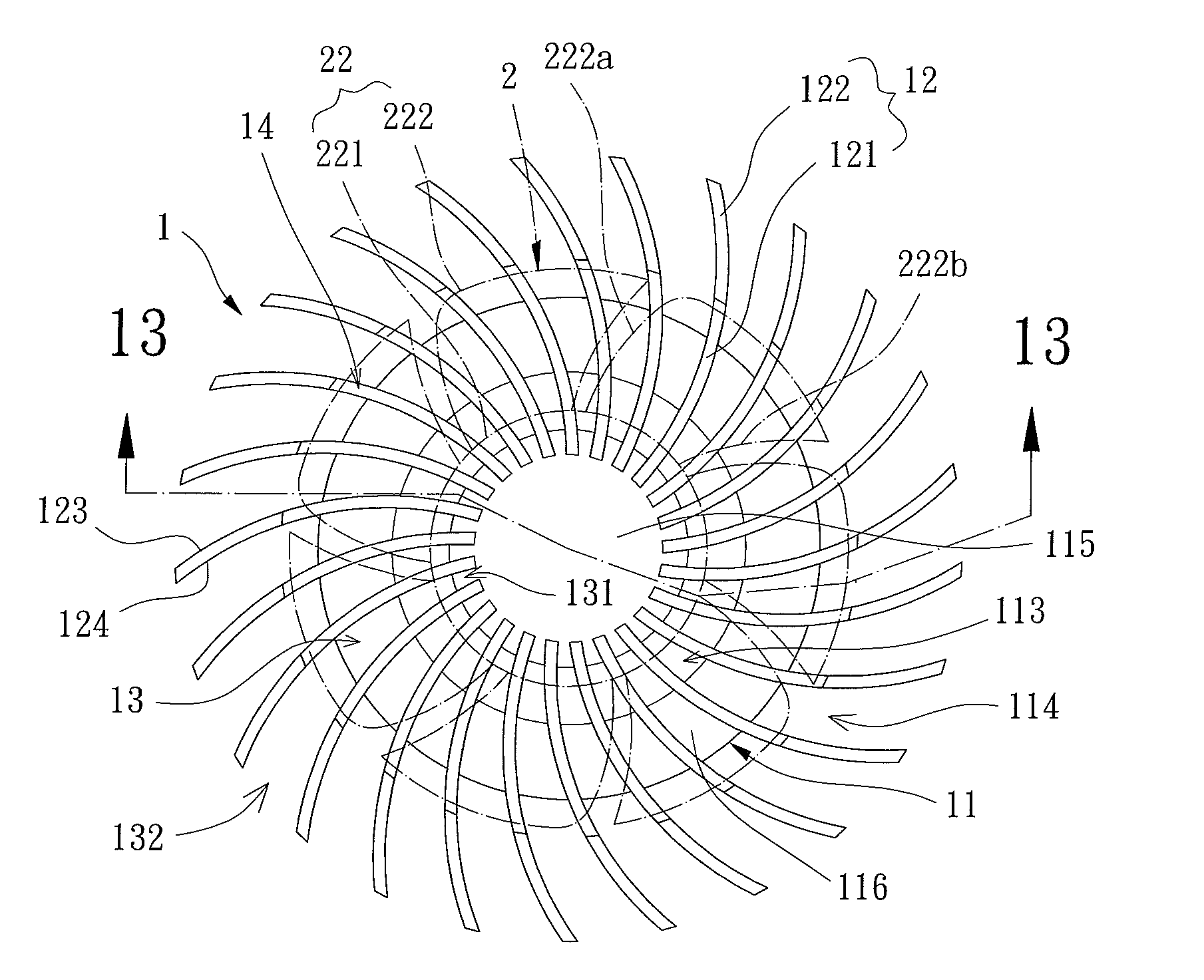

[0031]Referring to FIG. 5, a cooling module of the present invention is shown. The cooling module includes a heat sink 1 and a fan unit 2 and is used to lower the temperature of a heat-generating unit of an electronic product. The heat sink 1 is made of a material with high thermal conductivity, such as aluminum, copper, or magnesium-aluminum ally. The fan unit 2 is mounted on a side of the heat sink 1, and another side of the heat sink 1 connects with the heat generating unit indicative of the numeral “3,” with the heat generating unit 3 being a LED light in this embodiment. However, the heat generating unit 3 is not limited to the LED light; that is, a central processing unit or a chip set is also applicable.

[0032]The heat sink 1 has a base plate 11, a plurality of fins 12, and a plurality of air-guiding channels 13. The base plate 11 has a first surface 111 and a second surface 112 oppositely arranged at two sides of the base plate 11. Besides, the base plate 11 is preferably in ...

second embodiment

[0039]Accordingly, with the above-illustrated design of the base plate 11 of this second embodiment, the cool air entering the fan unit 2 can still straightly send to and contact with the base plate 11 for the heat exchange process. Moreover, areas of interfaces between the air-guiding channels 13 and the outside of the cooling module can be further increased for the inward and outward air flows to be exhausted fast.

[0040]Now turning to FIGS. 11 through 13, a cooling module of a third embodiment of the present invention is shown. In comparison with the base plate 11 of the second embodiment, the outlet 113 of the base plate 11 in the present embodiment is formed in a ring shape to separate the base plate 11 into a core portion 115 and an outer portion 116. The core portion 115 is arranged on the center of the base plate 11 and axially aligned with the hub 221 of the fan wheel 22. The outer portion 116 is radially sandwiched between the outlet 113 and the auxiliary outlet section 114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com