Non-Modal Interplate Microwave Heating System and Method of Heating

a microwave heating and non-modal technology, applied in microwave heating, electric heating, electric/magnetic/electromagnetic heating, etc., can solve the problems of troublesome constraints on specimen orientation and placement, power and voltage requirements, and complex control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

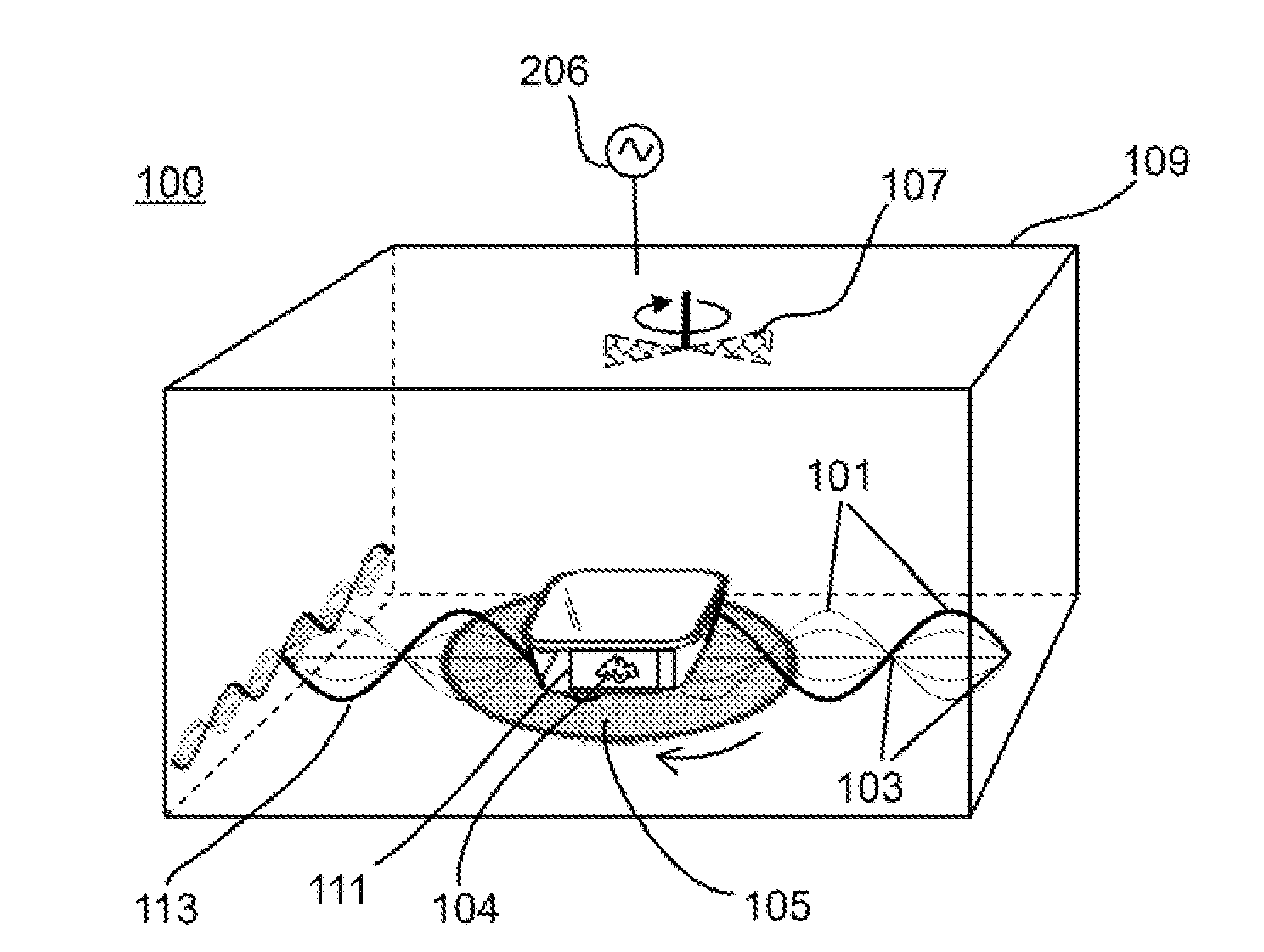

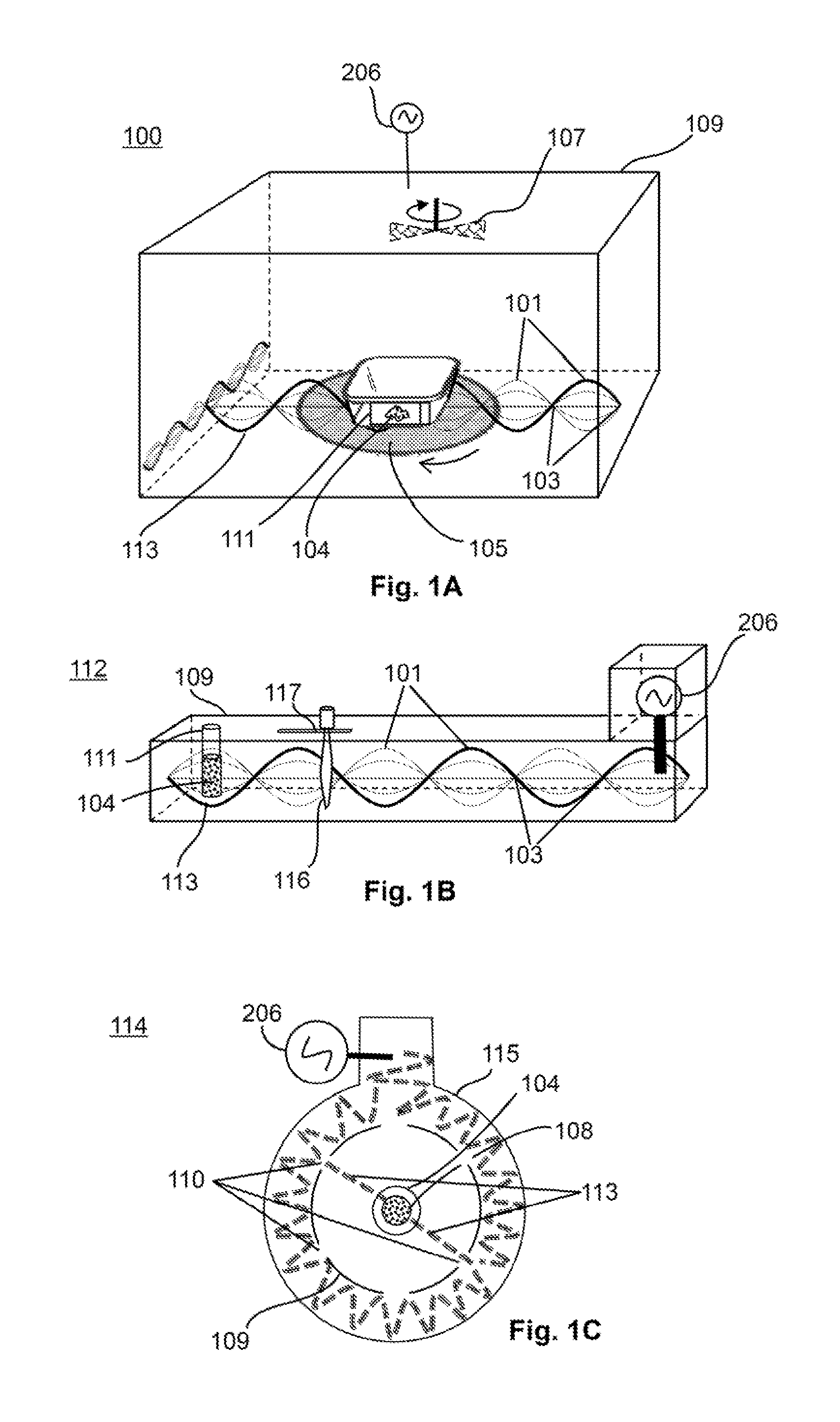

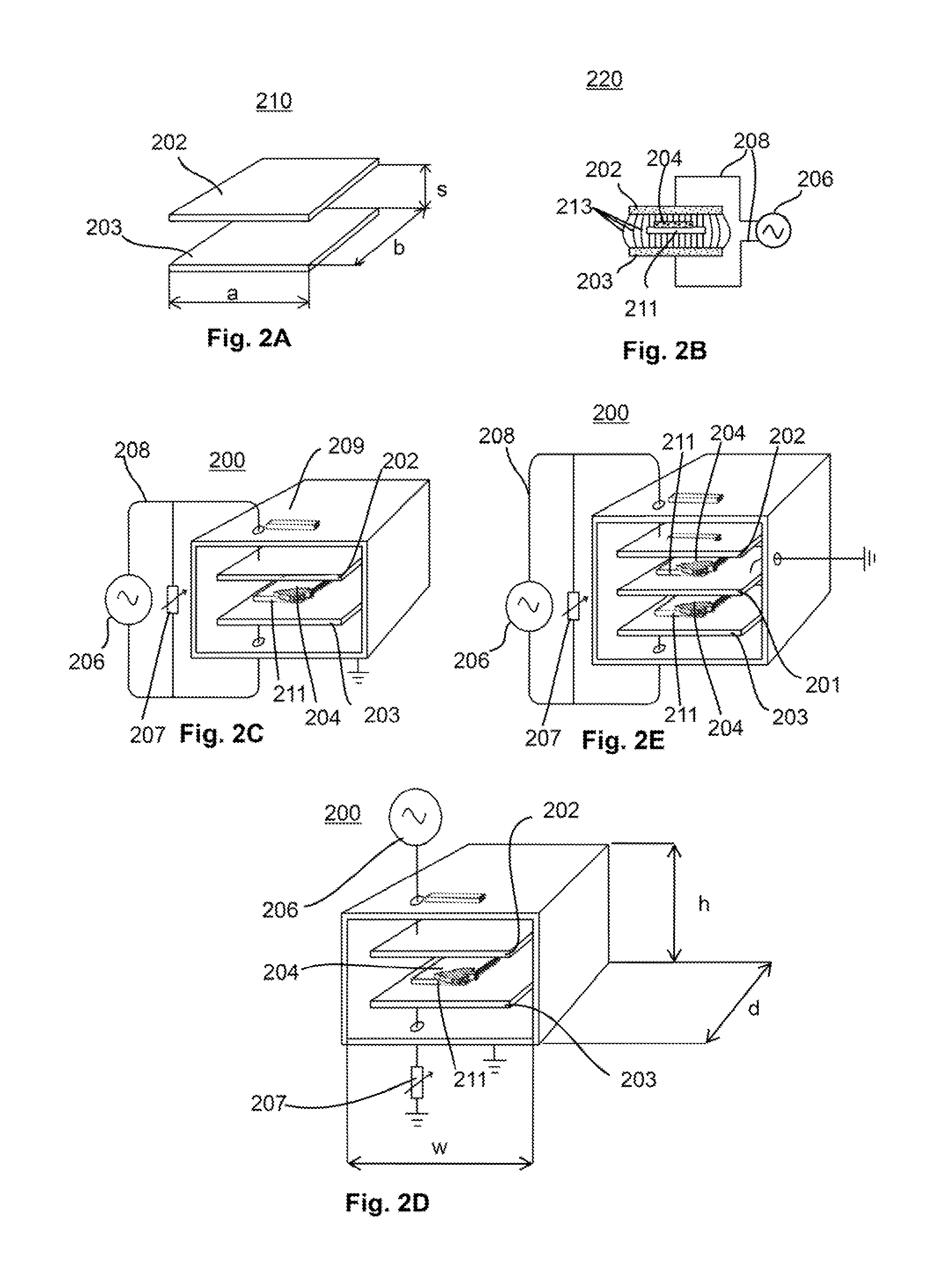

[0056]The various embodiments of the invention presented herein illustrate how to practice the invention and the various advantages the invention has over existing methods.

[0057]By directly heating a load using a non-modal interplate microwave applicator as described herein or equivalent variations thereof, a number of beneficial effects may be achieved including that the non-modal interplate microwave applicator may be made very small, it may require only a very low power while providing uniform, well-controlled heating of loads positioned between the plates; the non-modal interplate microwave applicator may be formed automatically by bringing the plates together automatically which enables a load to be inserted in or removed from between the plates of the applicator; the non-modal interplate microwave applicator may be built into load holders that move from station to station; independent applicators for a plurality of loads may be grouped together in a compact manner to heat tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com