Foldable and flexible laminated mat

a laminated mat, flexible technology, applied in the direction of knotting, braiding, knitting, etc., can solve the problems of inflexibility of hardwood chair mats, high cost, and difficult movement of chair mats, especially the larger ones, and achieve the effect of sufficient thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

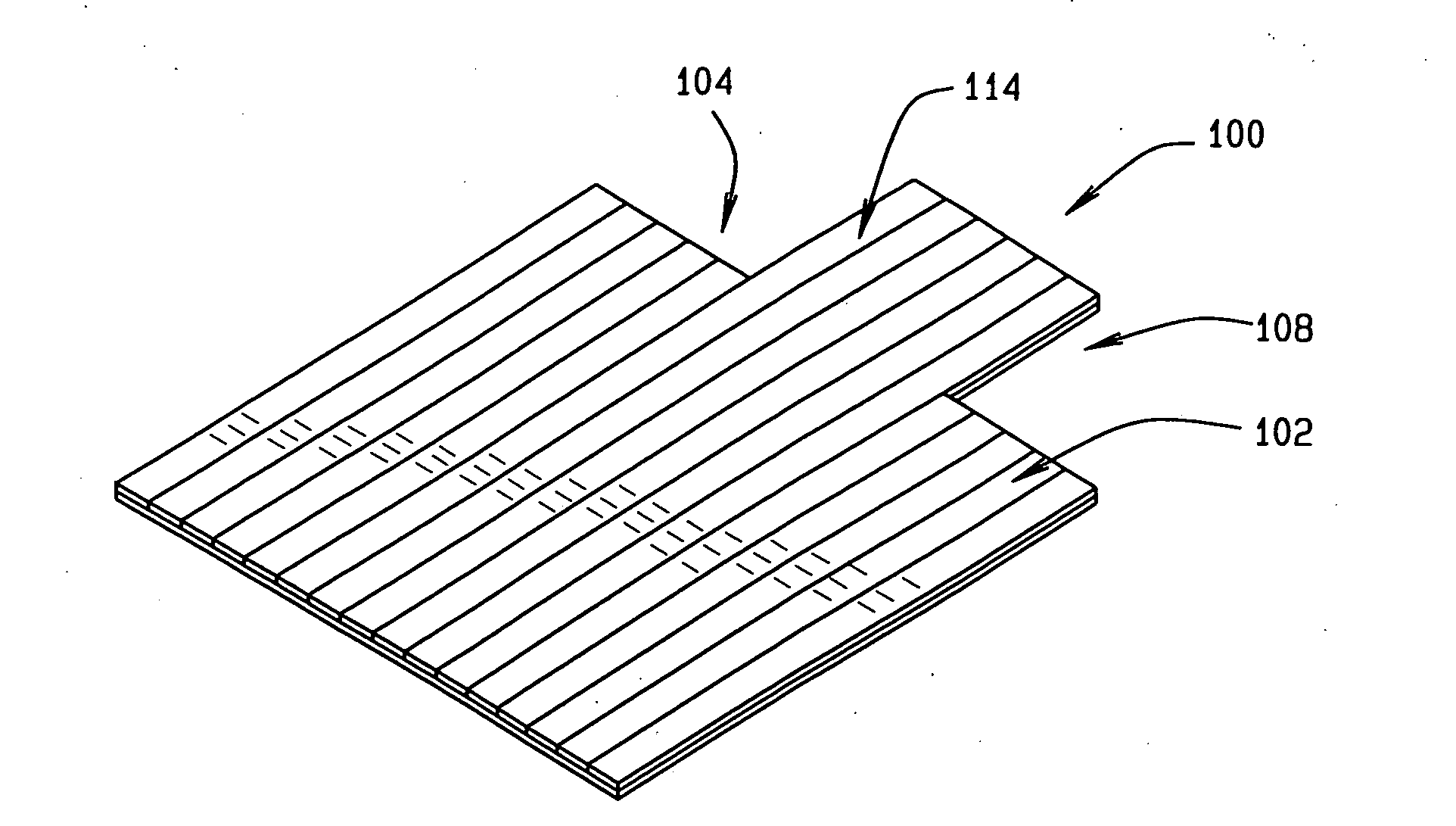

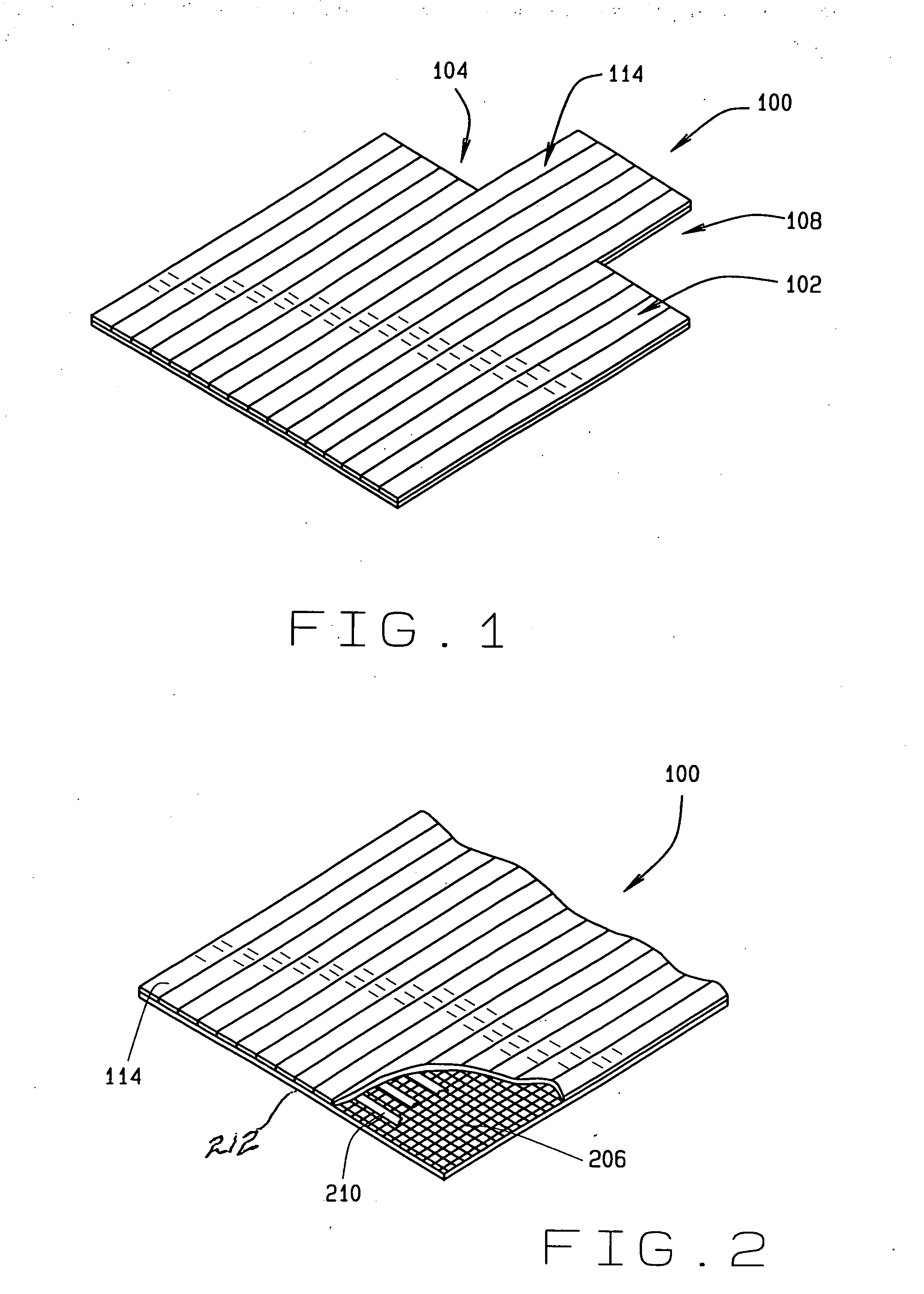

[0023]According to the present invention, various views of the foldable and flexible laminated mat or pad of this invention are shown in FIGS. 1 and 2. In the embodiment of the present invention, comprising medium density fiberboard laminated planks, these are laid in adjacency and a felt or sisal backing provides both the adherence of the planks in adjacency, and furnishes a backing for resting upon the floor, in addition to functioning as a living hinge when the mat or pad is to be rolled up, or folded, for storage or shipment. The details of the invention can be better understood by referring to FIG. 1. This is a perspective of the present pad or mat 100, and the pad is constructed including a plurality of elongated medium density fiberboard planks 102, arranged lengthwise in a side by side manner where the long side edge of each plank can be abutted against the adjacent long side edge of the adjacent planks. The abutting relationship between the planks can form a mat, as at 114....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com